SdAufKla

Active member

Well, I haven't posted anything here on MA in a really (really!) long time, mostly because I haven't done any personal modeling work in a couple of years. However, after I finished up the last project that I was working on (a very large, 1/72 scale diorama of Vietnam Fire Support Base RIPCORD which can now be seen in the atrium of the SC State Museum at the entrance the the SC CRR&MM), I decided to build something that had absolutely zero olive drab on it!

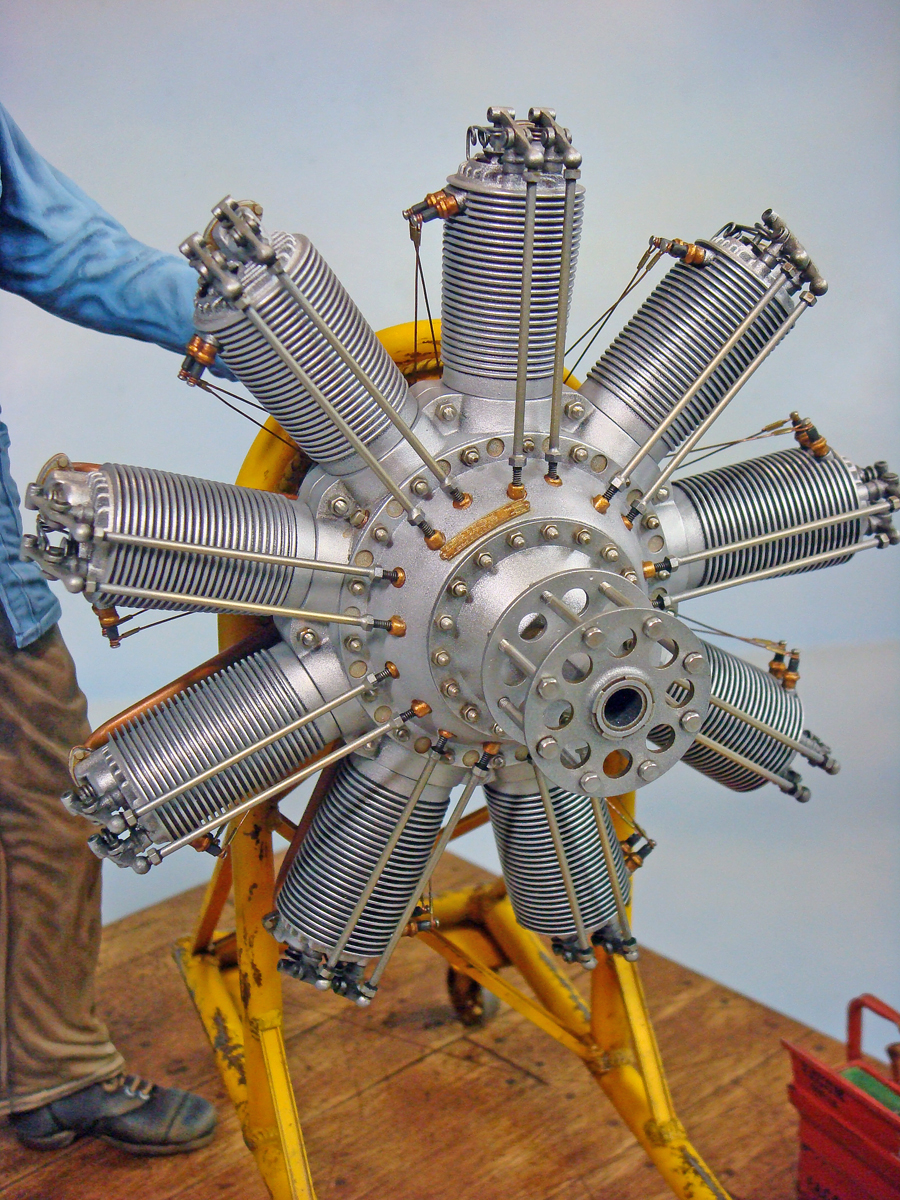

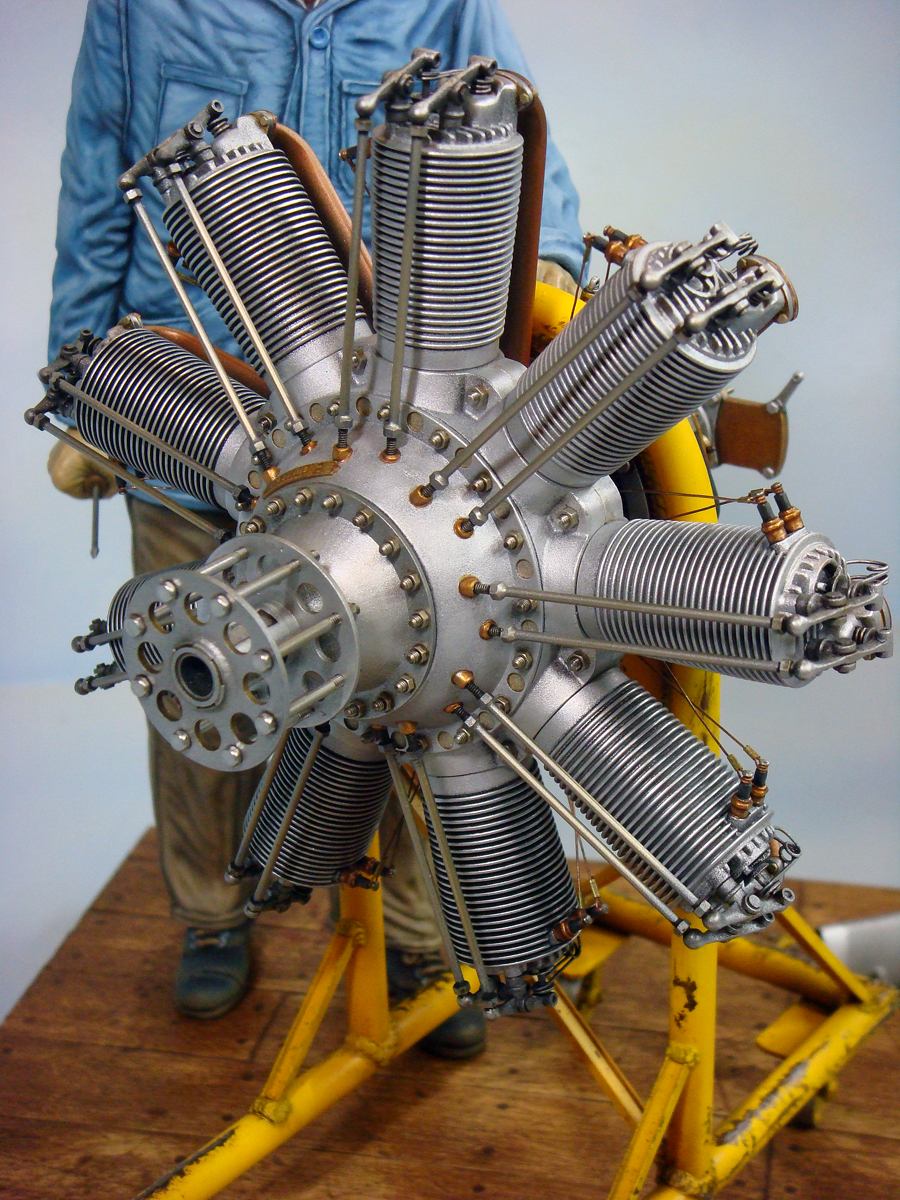

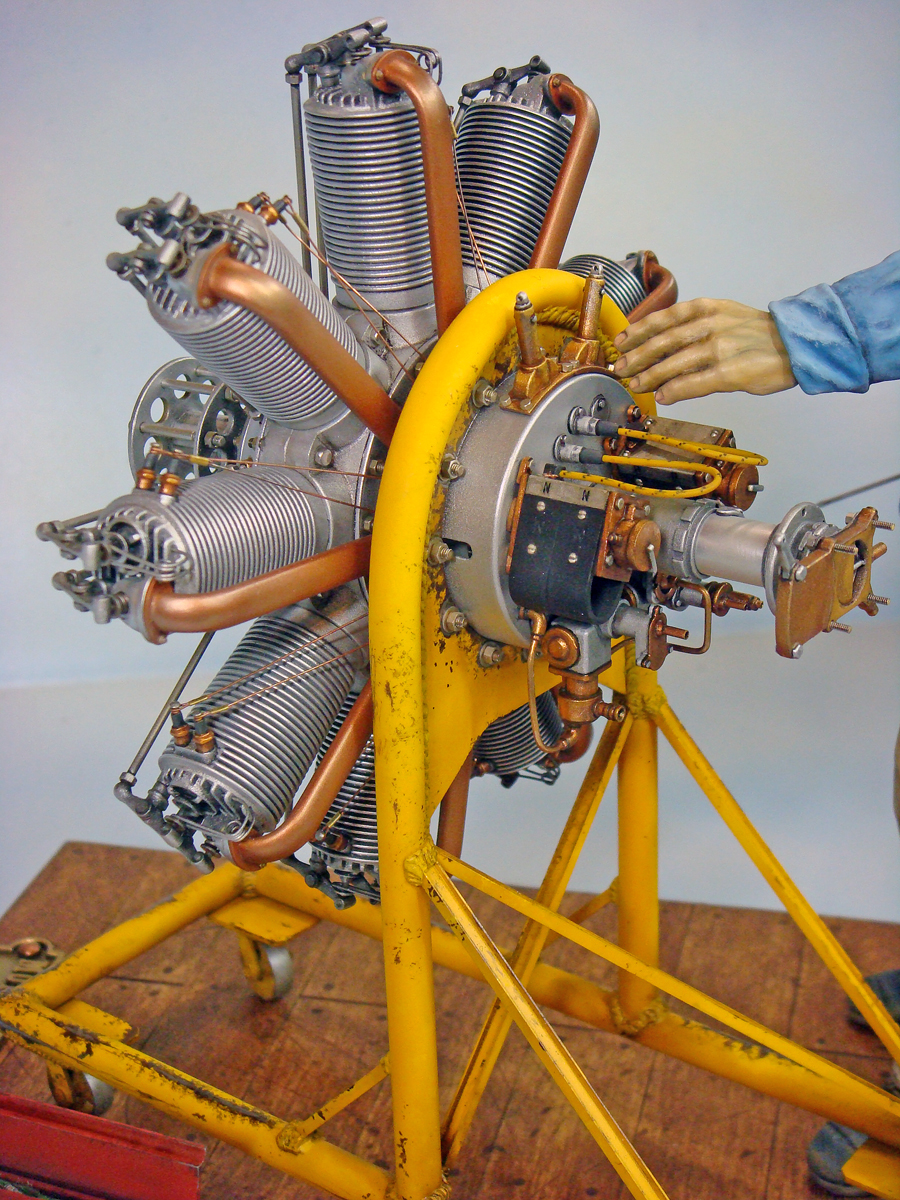

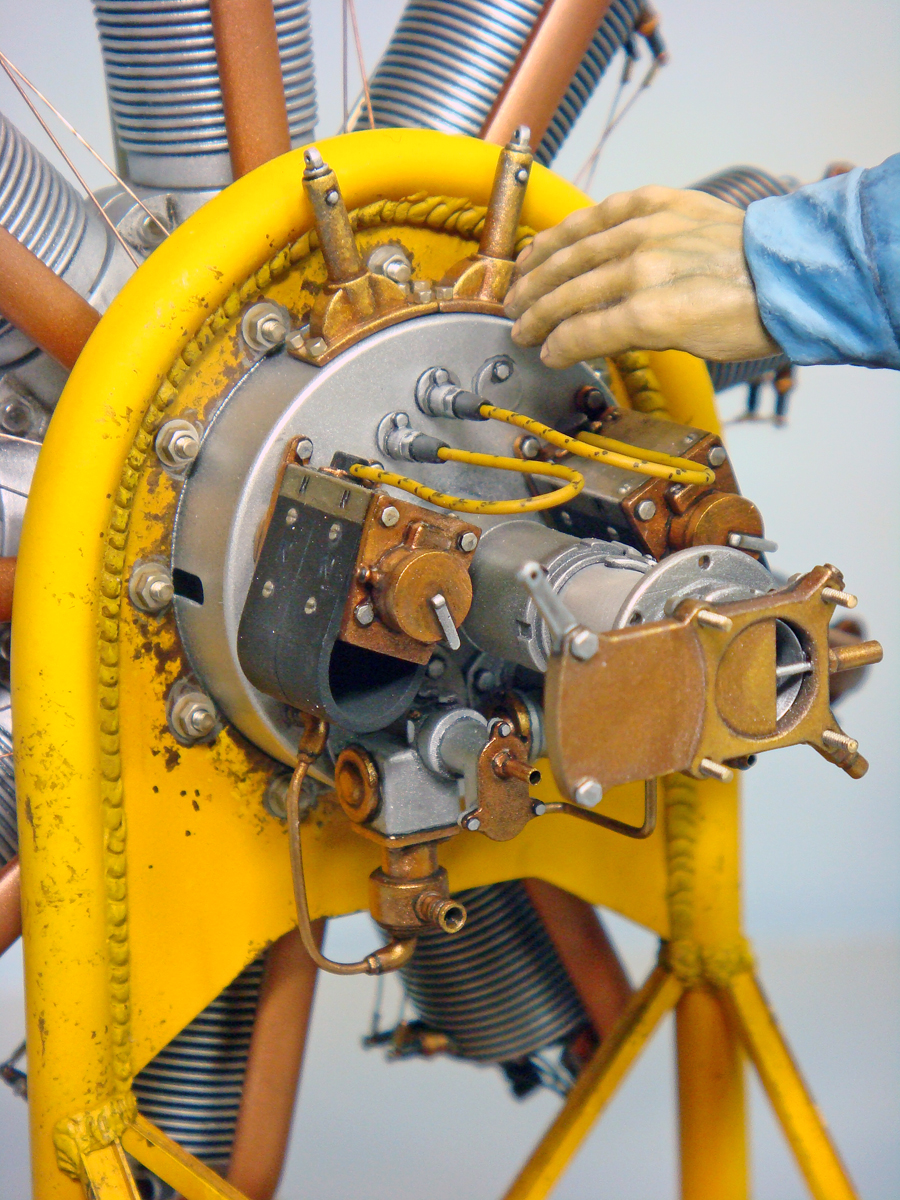

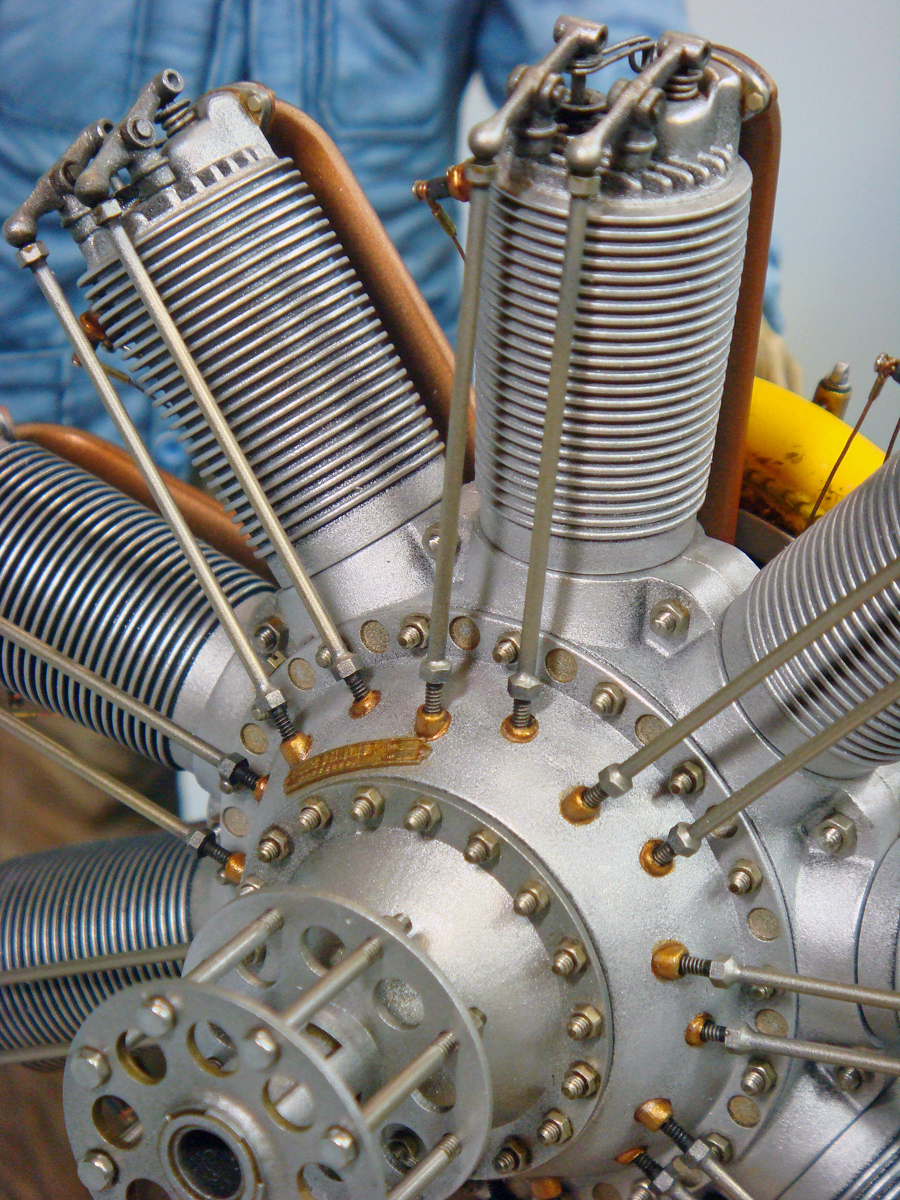

This is the Hasegawa 1/8 Clerget 9B Rotary Engine in a Clerget-Blin & Cie. factory setting. I admit to swallowing the red-blue pill and taking a rather deep dive down into the ol' research rabbit hole. The engine build features a lot of 3D parts that I designed and printed myself along with replacing most of the nuts and bolts with miniature hardware. I made new valve springs from brass wire and did a ton more scratch-building on various details. I'll spare you the boring blow-by-blow and tedious repetition of "and then I added ____ ..." The kit needs a lot of work. Out of the box it's a fair representation, but most of the details on the accessory case side are missing, and the details that are there are... well, let's just say... "questionable" in regards to accuracy.

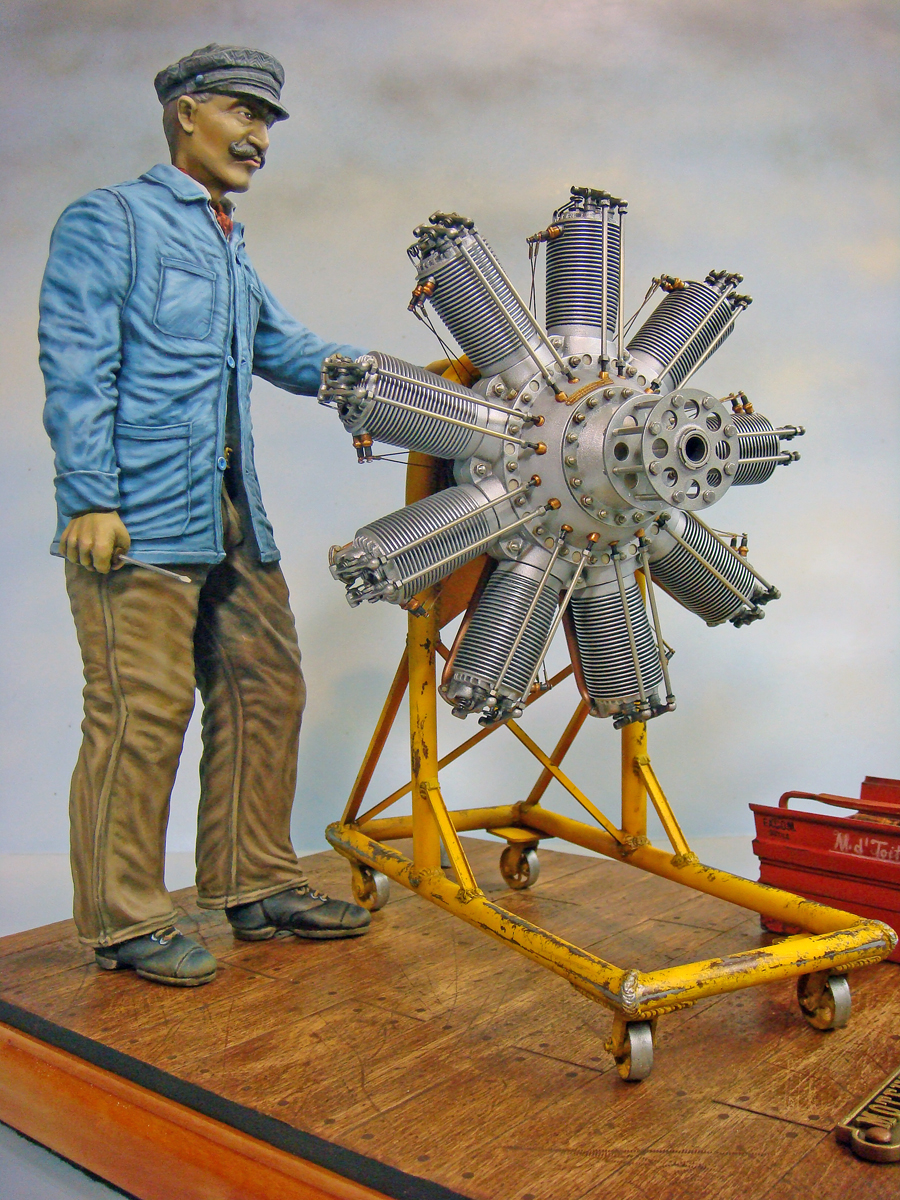

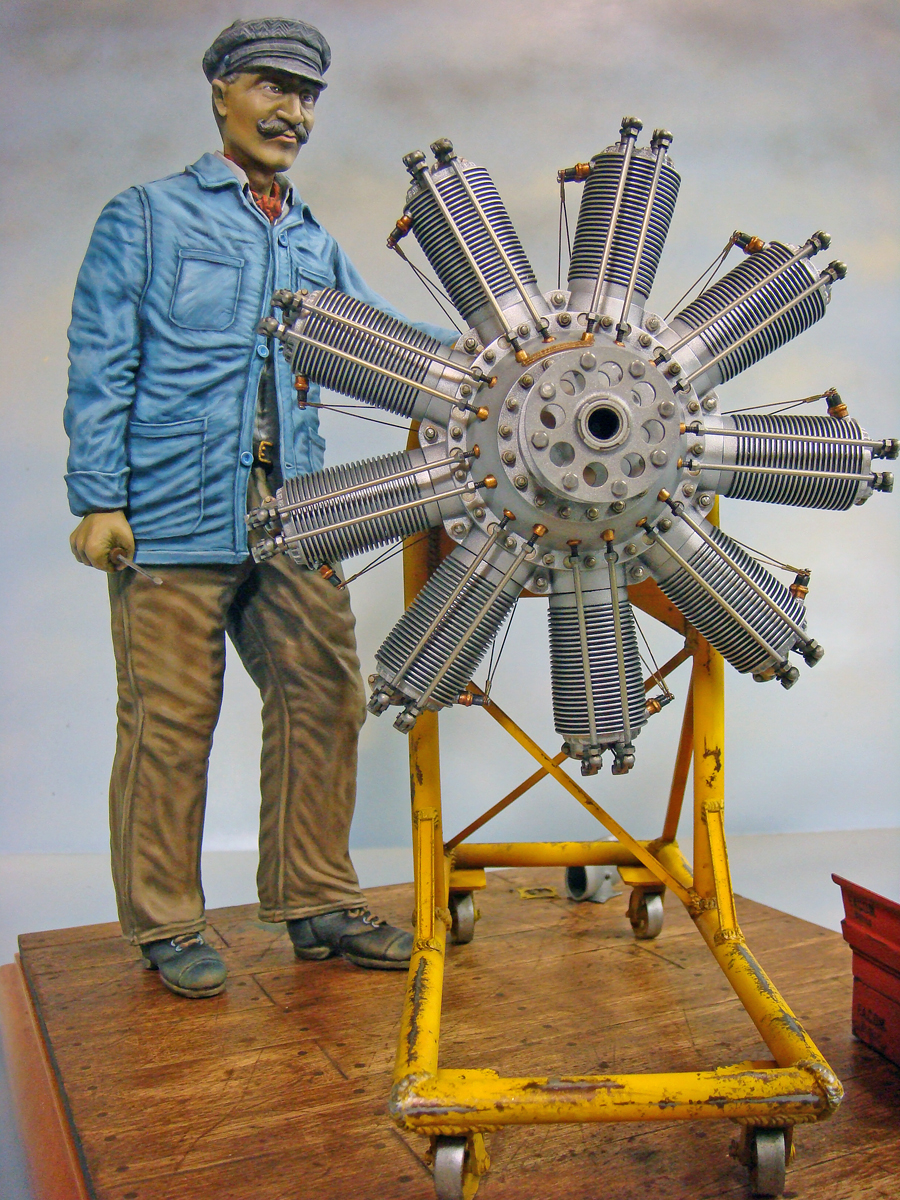

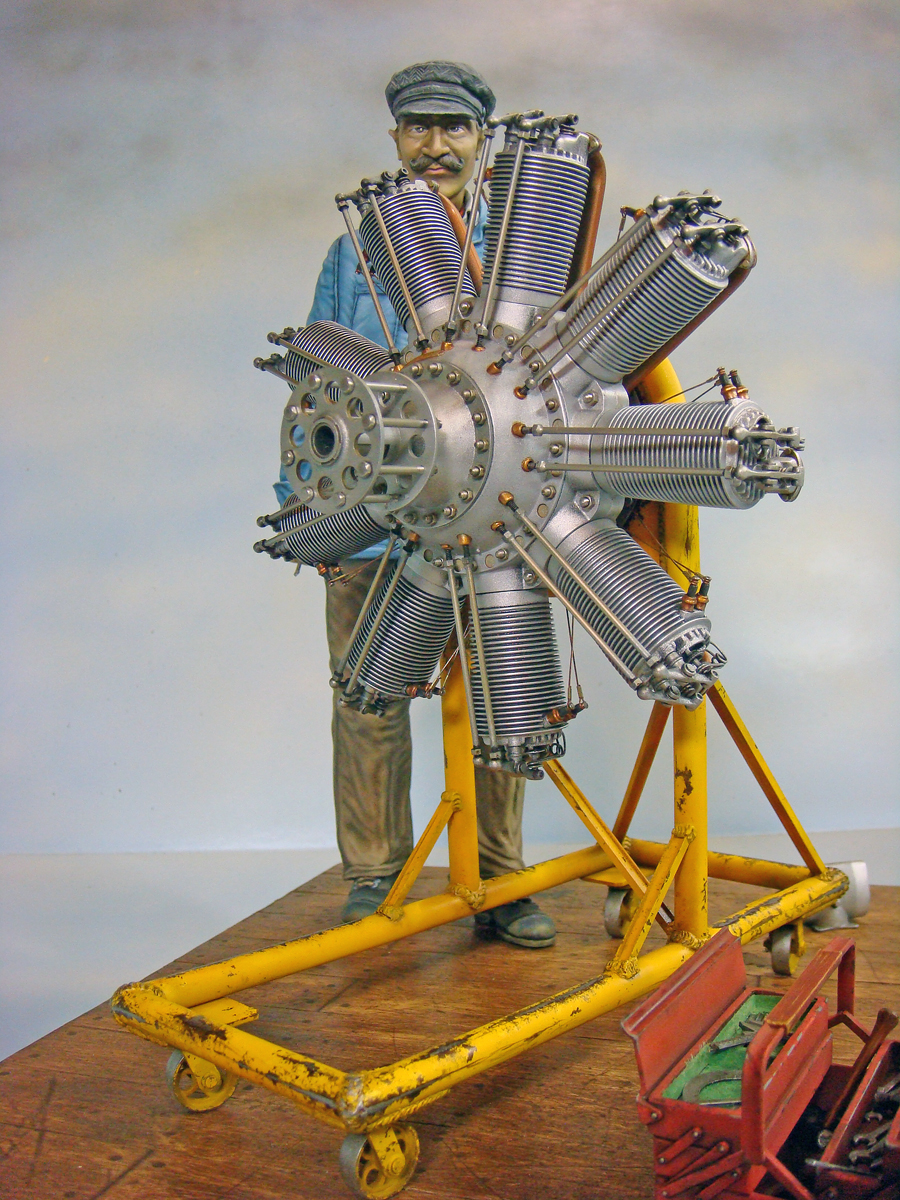

The engine stand is scratch-built out of Evergreen styrene stock with home designed and 3D printed castor wheels. I used two-part epoxy putty to replicate the weld beads. The kit provided engine stand sort of represents something that might be seen in a museum and is not a proper work-assembly type stand.

The toolbox and tools are 3D designs I downloaded from a website called TinkerCad. It features 2D and 3D designs that have been uploaded by their creators who want to share them. I did do some re-mixing (i.e. design modifications) on the toolbox and tools to get what I was looking for, but I can't claim credit for the original CAD work on those. I did print them on my desktop 3D printer, though.

The 1/8 scale French factory worker is an original 3D sculpt and print by a friend of mine, Luis Hidalgo (aka "Holden8702" on FaceBook). Luis does all sorts of custom 3D designs and prints, mostly figures though, in all scales and subjects. I did a little work making some minor changes and additions, all the normal kinds of stuff you might do with any figure. I painted the figure in artist oils over acrylic undercoats. He's mostly there to add a sense of scale for the viewer. The prototype engine is about 40" in diameter which translates into 5" in diameter in 1/8 scale. That is, it's ginormous! Without the figure (which is over 8" tall), the engine model lacks anything that puts its real size into context for the viewer. Anyway, that's Michel's job!

The base is made of strips of wood veneer that's sold to edge plywood (usually for making shelves or cabinets). It's hot-glued down to a piece of 1/4" plywood. I drilled holed and inserted pegs made of wooden toothpicks to simulate the fastening of the factory floor boards. After sanding, I finished up the raw edges of the thin plywood with Durham's Water Putty and stained and distressed the "floor." The title plate is a copy of the prototype brass engine data plate. I had made a 1/8 scale copy to go on the engine (a detail conspicuously missing from the kit), so I scaled that up to fit on the base and printed it out.

This is the Hasegawa 1/8 Clerget 9B Rotary Engine in a Clerget-Blin & Cie. factory setting. I admit to swallowing the red-blue pill and taking a rather deep dive down into the ol' research rabbit hole. The engine build features a lot of 3D parts that I designed and printed myself along with replacing most of the nuts and bolts with miniature hardware. I made new valve springs from brass wire and did a ton more scratch-building on various details. I'll spare you the boring blow-by-blow and tedious repetition of "and then I added ____ ..." The kit needs a lot of work. Out of the box it's a fair representation, but most of the details on the accessory case side are missing, and the details that are there are... well, let's just say... "questionable" in regards to accuracy.

The engine stand is scratch-built out of Evergreen styrene stock with home designed and 3D printed castor wheels. I used two-part epoxy putty to replicate the weld beads. The kit provided engine stand sort of represents something that might be seen in a museum and is not a proper work-assembly type stand.

The toolbox and tools are 3D designs I downloaded from a website called TinkerCad. It features 2D and 3D designs that have been uploaded by their creators who want to share them. I did do some re-mixing (i.e. design modifications) on the toolbox and tools to get what I was looking for, but I can't claim credit for the original CAD work on those. I did print them on my desktop 3D printer, though.

The 1/8 scale French factory worker is an original 3D sculpt and print by a friend of mine, Luis Hidalgo (aka "Holden8702" on FaceBook). Luis does all sorts of custom 3D designs and prints, mostly figures though, in all scales and subjects. I did a little work making some minor changes and additions, all the normal kinds of stuff you might do with any figure. I painted the figure in artist oils over acrylic undercoats. He's mostly there to add a sense of scale for the viewer. The prototype engine is about 40" in diameter which translates into 5" in diameter in 1/8 scale. That is, it's ginormous! Without the figure (which is over 8" tall), the engine model lacks anything that puts its real size into context for the viewer. Anyway, that's Michel's job!

The base is made of strips of wood veneer that's sold to edge plywood (usually for making shelves or cabinets). It's hot-glued down to a piece of 1/4" plywood. I drilled holed and inserted pegs made of wooden toothpicks to simulate the fastening of the factory floor boards. After sanding, I finished up the raw edges of the thin plywood with Durham's Water Putty and stained and distressed the "floor." The title plate is a copy of the prototype brass engine data plate. I had made a 1/8 scale copy to go on the engine (a detail conspicuously missing from the kit), so I scaled that up to fit on the base and printed it out.

Last edited: