Finally got some bench time...

Thanks you guys for the kind remarks

Bob, you are correct, usually start with a paper template then shape it to a final fit. Those scribe marks on the cab where to help me bend both sides the same.

Update...

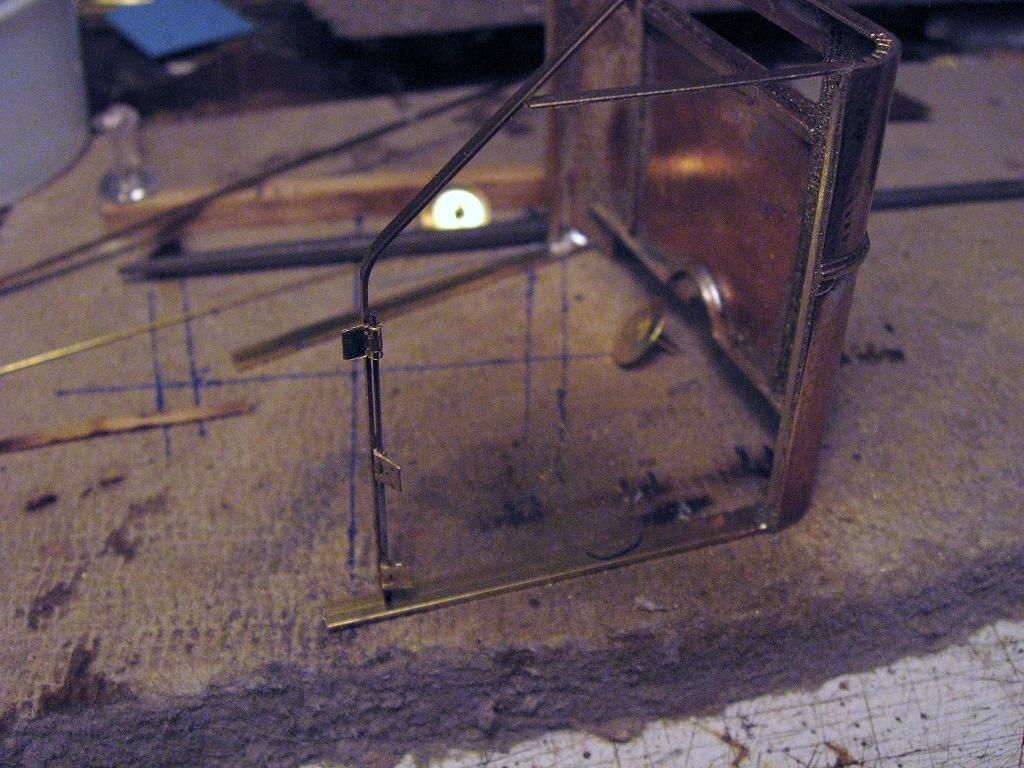

Mock up.......

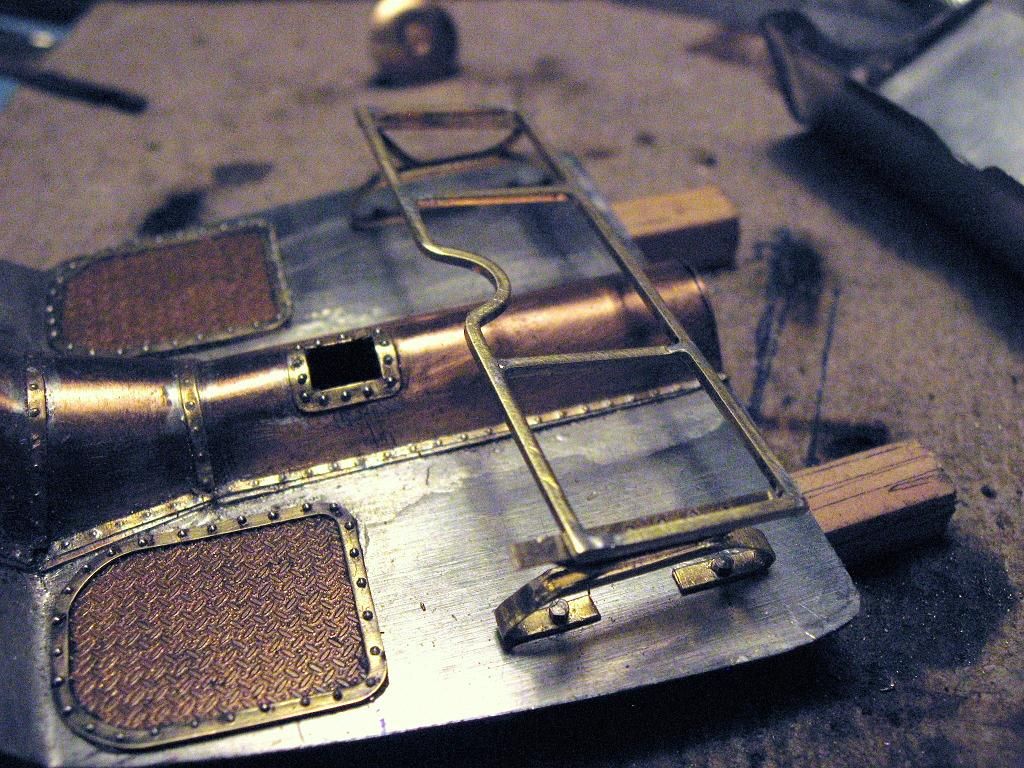

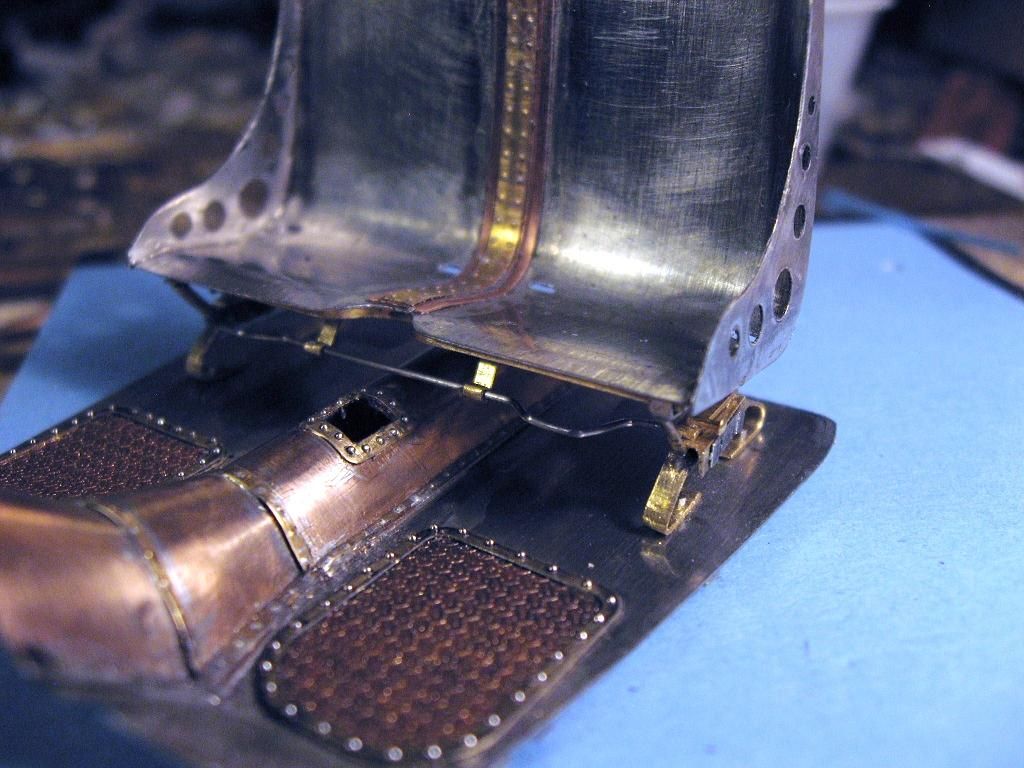

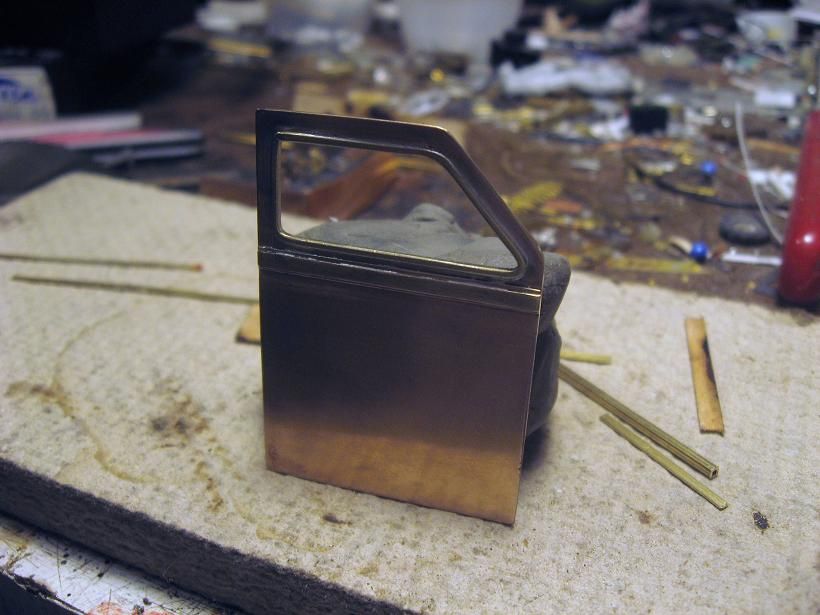

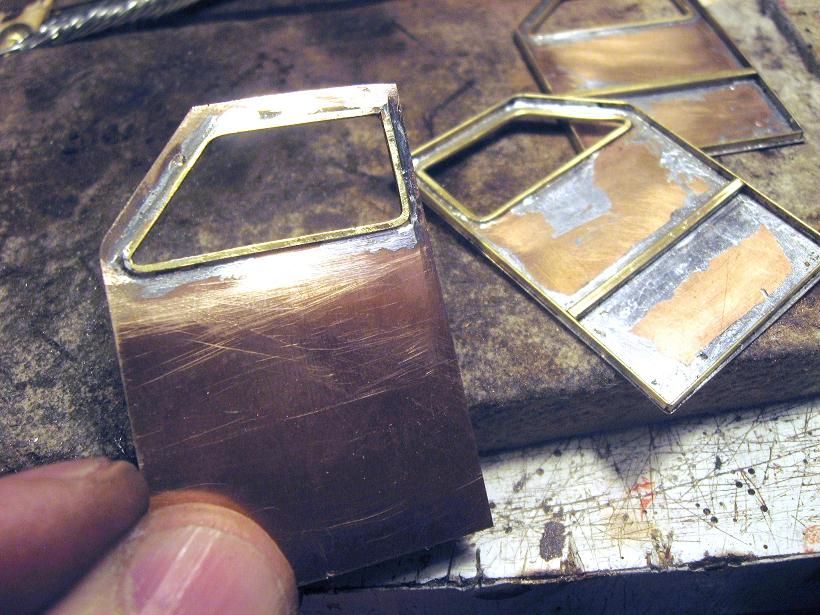

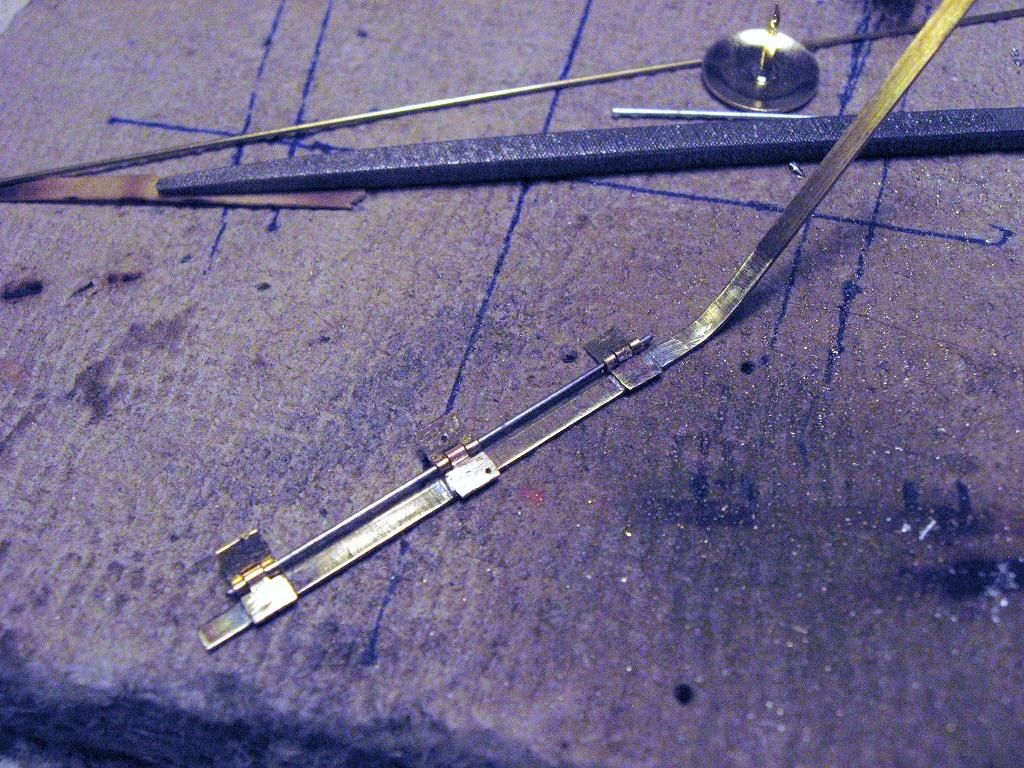

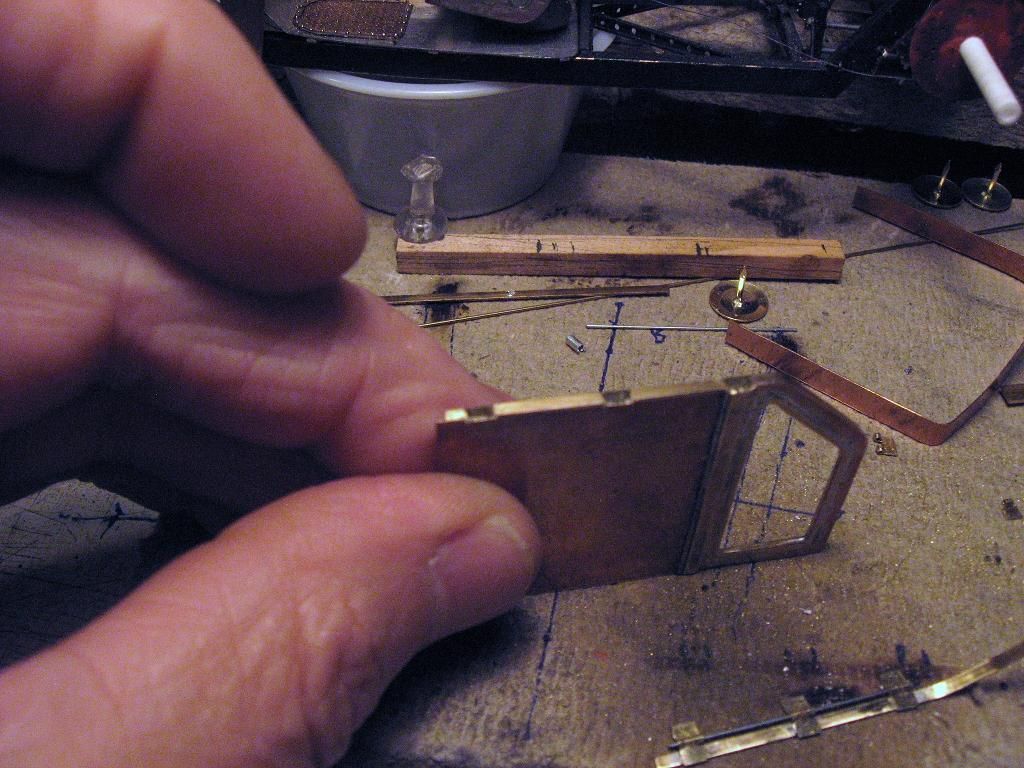

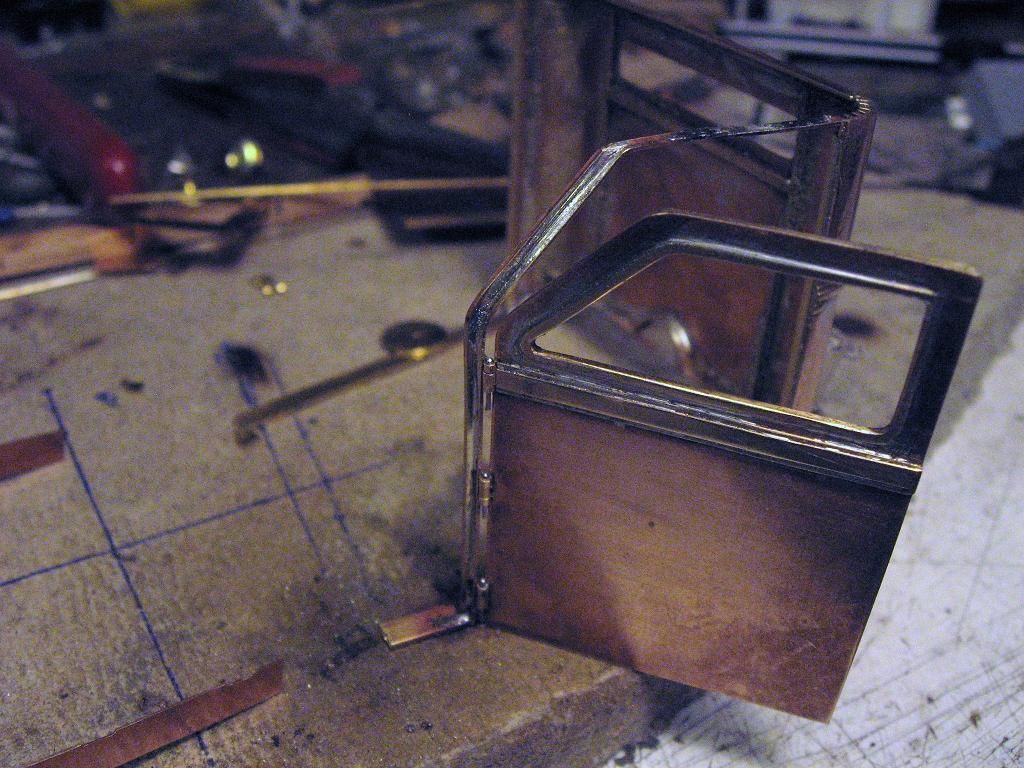

Inner door skins....

Stuck on some plastic door handles to see what it will look like..

The doors are not soldered together yet, still need some glass...

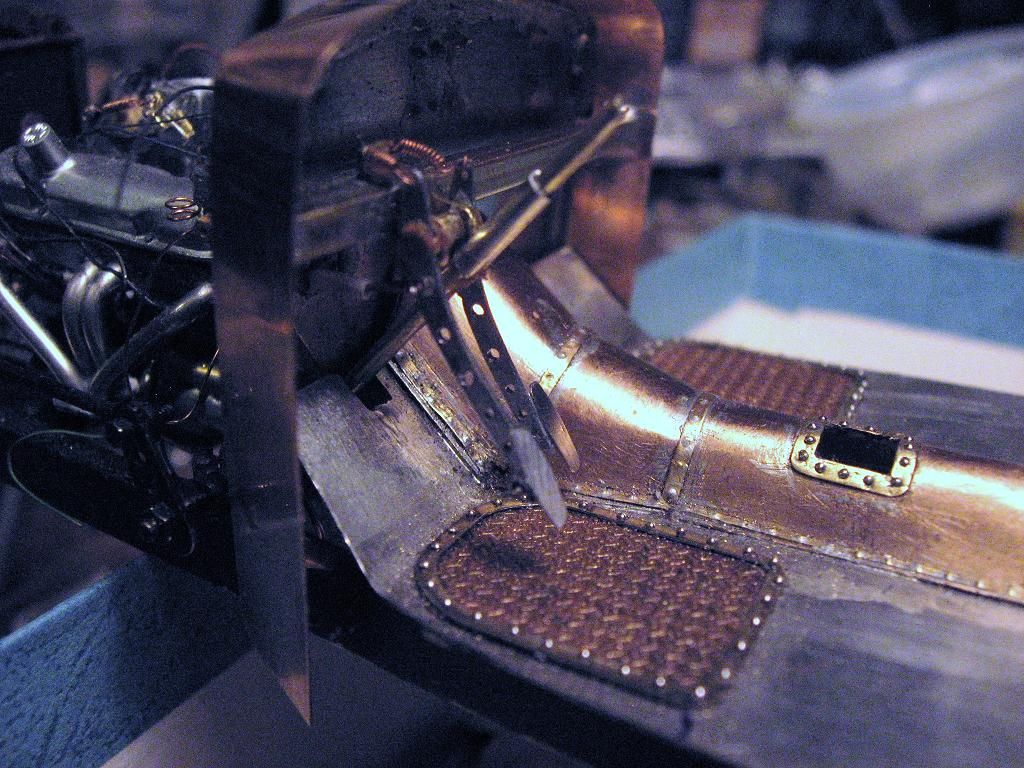

Working on more of the cab, adding interior framing...

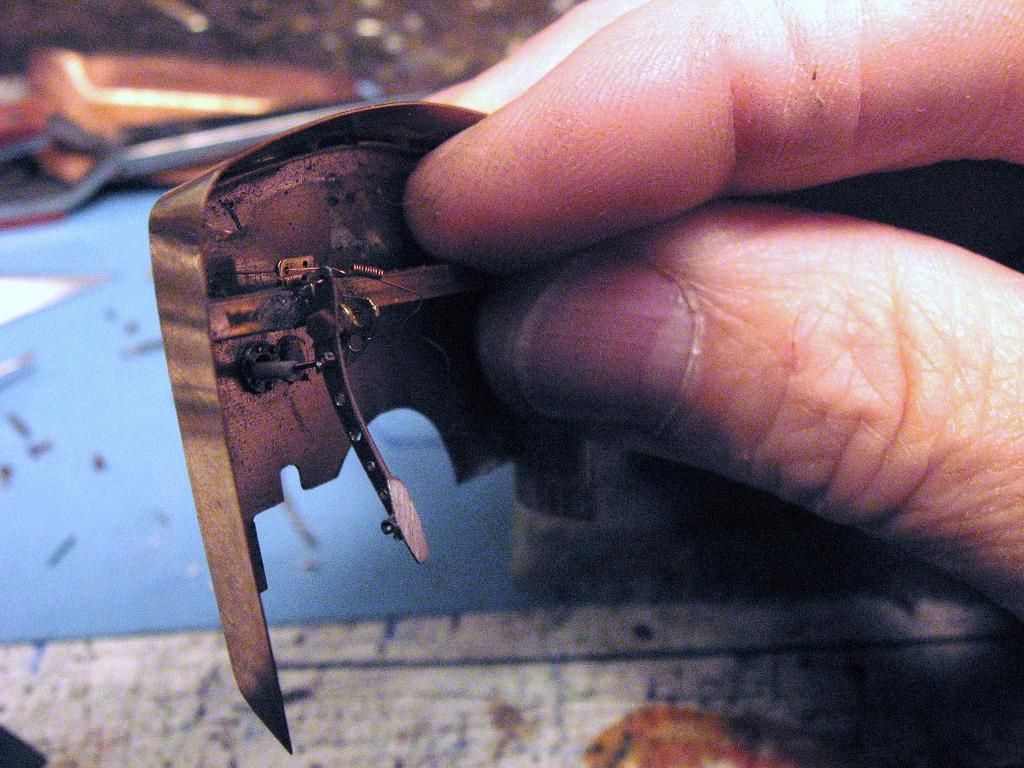

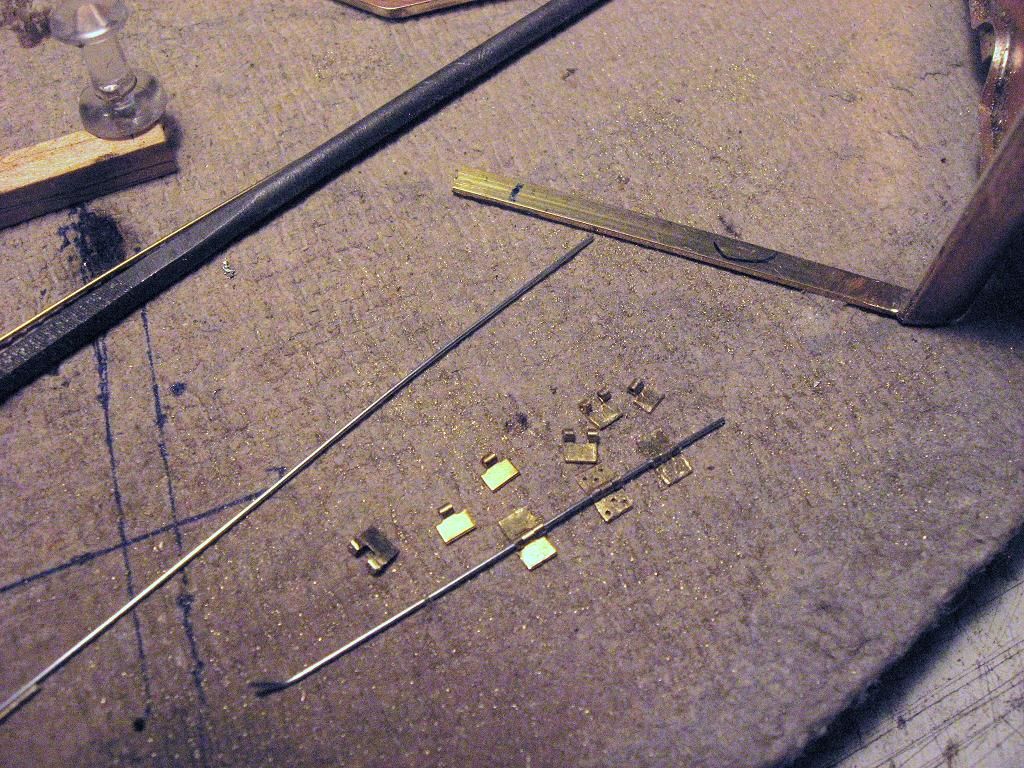

cut down some small hinges from 'Micro- Mark'....

Mock up time, the cowling piece is not attached yet....

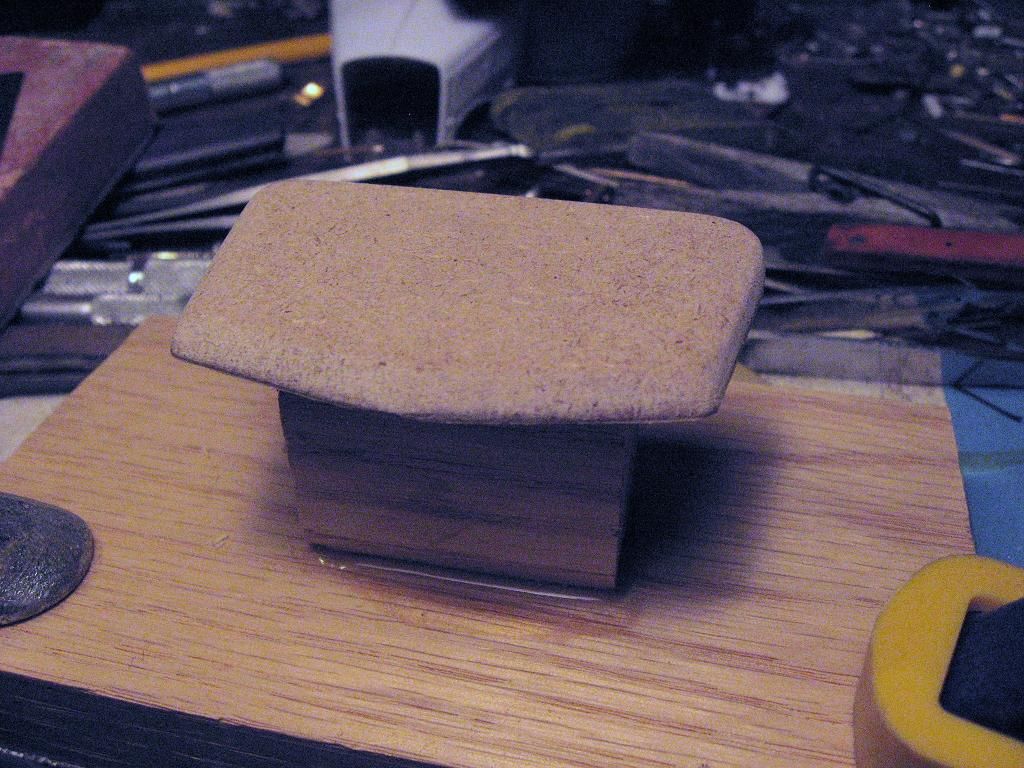

Here is the final version of the roof form, MDF from a piece of laminate flooring.

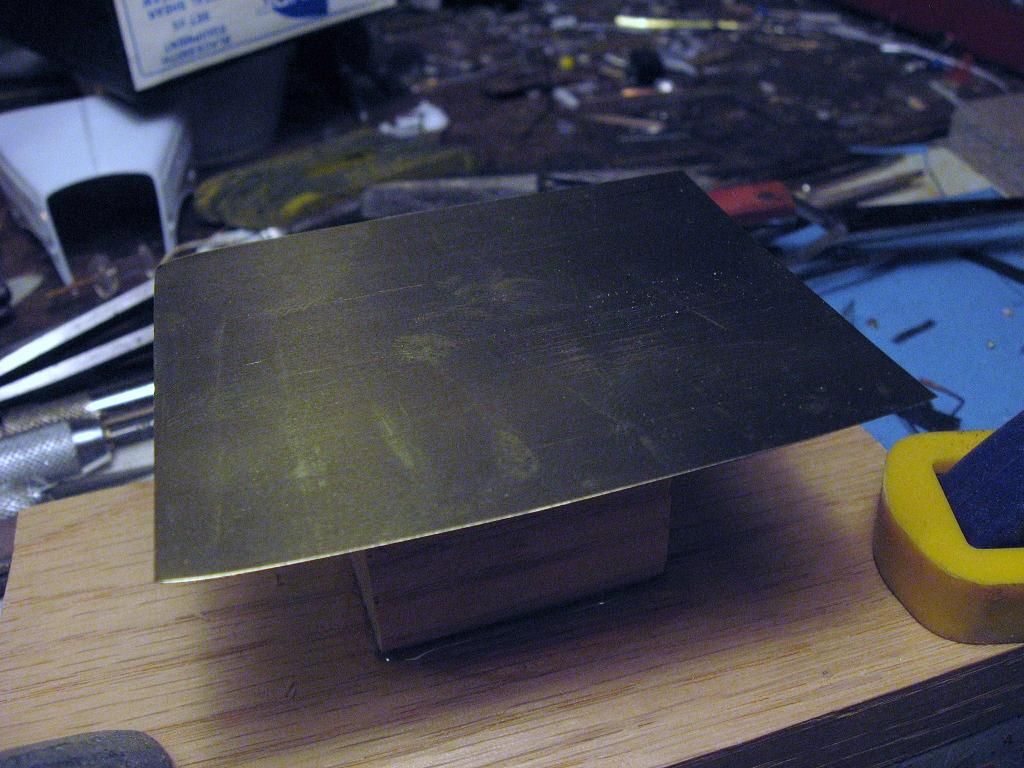

Roof is .005 brass sheet ....

Heated to cherry red add beat to fit...

since this will get painted I was able to 'pie cut' the corners and fill with solder...

That is all for now, thanks for looking in!!

Randy

OK, you got some cool daddy tools. What's that thing you beat the roof into submission with? is it pneumatic> (I didn't take metal shop in school)

How do you keep the solder from running up in the hinge pin?

Stunning work Randy!