-

Modelers Alliance has updated the forum software on our website. We have migrated all post, content and user accounts but we could not migrate the passwords.

This requires that you manually reset your password.

Please click here, http://modelersalliance.org/forums/login to go to logon page and use the "Forgot your Password" option.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Adventures from Woodland

- Thread starter jeaton01

- Start date

jeaton01

Well-known member

I'm far enough along on my new workshop that I can start decongesting what will become the dedicated plastic model building area in my first workshop. I moved out the big table that was optimised for large R/C model building and built a new bench that extends my plastic modeling bench 80 more inches, 33 inches deep as is the existing bench. It is topped with ceiling tile and then glass. I have plenty of glass as I years ago took on the remaining inventory from a company that was going out of the pay phone booth business. Still have 4 or 5 unused panes of 1/4 inch tempered glass. Probably I will use the rest as shelves for future display cases. The old bench served both R/C and plastic models and was also where my photo backdrop was, and it seemed like every time I had set up for photos that I needed to do something requiring that space. The new bench setup makes it so I can have 3 or 4 model projects going at once and the photo setup is now on the wall so I can just roll it up if I need the bench space.

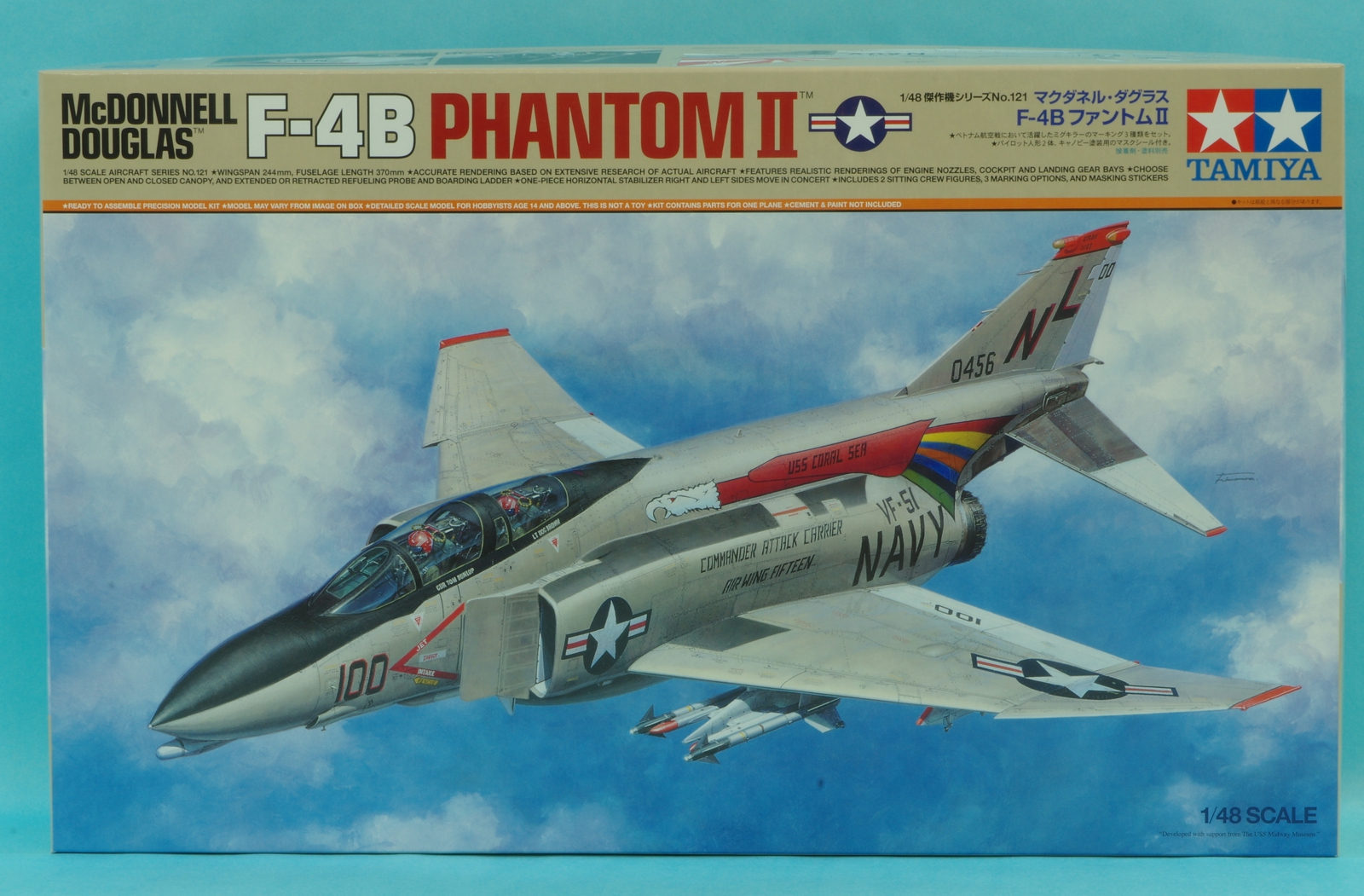

I've already used the new photo setup. Yesterday a box came in the mail and I had no idea what it might be. Turned out to be the 1/48 Tamiya F-4 which I had ordered in the last week of December, just now arriving. I had forgotten all about it.

I think pretty soon I may be able to finish up some models. Laid out on the bench are the nearly done figures from the Airfix Hurricane Ready For Battle set, the 1/72 Italeri B-26K awaiting decals, two Eduard 1/48 Yak 3's, a Hobbycraft Sea Fury my grandson is building, the Hobbycraft 1/48 Arrow, and a Pegasus Martin Baker MB.5.

I've already used the new photo setup. Yesterday a box came in the mail and I had no idea what it might be. Turned out to be the 1/48 Tamiya F-4 which I had ordered in the last week of December, just now arriving. I had forgotten all about it.

I think pretty soon I may be able to finish up some models. Laid out on the bench are the nearly done figures from the Airfix Hurricane Ready For Battle set, the 1/72 Italeri B-26K awaiting decals, two Eduard 1/48 Yak 3's, a Hobbycraft Sea Fury my grandson is building, the Hobbycraft 1/48 Arrow, and a Pegasus Martin Baker MB.5.

jeaton01

Well-known member

Progress report. The windows I ordered in December are now set to arrive after May 1. I put on the roof underlayment myself but after doing that it seemed easier to write the check to a roofing company to nail on the shingles. I decided to put on James Hardie planking as the quote I got for the wood to match my house was north of $8,000. Yeeowww! The planking was a quarter of that. It will look similar but will have a 4 inch pitch instead of 2 1/2. Putting on the house wrap now.

Really nice John, you're going to be done with a stick built shop before I finish tricking out roll off shop.

Heavens Eagle

Well-known member

The construction is coming along very well John! Thanks for the update.

jeaton01

Well-known member

We had our twelfth annual Helicopter Scale Masters this weekend at my club and I took way too many pictures. Many of these models are powered by gas turbine engines, the rest are electric. Nobody was flying an IC engine in in any of them. This is a pretty well attended event with people coming from as far as Germany and Chile.

I've put some pictures on my website, here is the link:

http://www.yolo.net/~jeaton/WDA/20220513hsm/20220513hsm.html

I've put some pictures on my website, here is the link:

http://www.yolo.net/~jeaton/WDA/20220513hsm/20220513hsm.html

Oh come on John, that's someone with a remote standing in front of the sheriff's chopper. Right???We had our twelfth annual Helicopter Scale Masters this weekend at my club and I took way too many pictures. Many of these models are powered by gas turbine engines, the rest are electric. Nobody was flying an IC engine in in any of them. This is a pretty well attended event with people coming from as far as Germany and Chile.

I've put some pictures on my website, here is the link:

http://www.yolo.net/~jeaton/WDA/20220513hsm/20220513hsm.html

Wow! thanks for sharing this John.

jeaton01

Well-known member

Another adventure in Woodland, sort of... My gas water heater gave up the ghost last week after 17 years, so I spent the last week or so getting it out of the basement. I bought an electric water heater and relocated it to the end of the basement that is closest to where we use the most hot water, which is maybe 30 feet away from where it was. The house was built in 1915 and a lot of the water pipe must have been installed near then, it was mostly 3/4 inch galvanized. I took out about 70 feet of that and replaced it with 3/4 inch copper. I thought about Pex but by the time I would have bought the tools nneded to work with that it would have cost more, so I went with copper. I had one joint out of maybe 15 that had a leak, so I feel pretty good about my workmanship. I hired an electrician to help with the wiring, that was installed in metal conduit. Modeling? Is that a thing?

17 years huh, I'd say you got your money's worth out of the old tank.

Good job on the soldering. Always a good skill to keep honed in.

Good job on the soldering. Always a good skill to keep honed in.

jeaton01

Well-known member

Getting near the finish, or closer, anyway. Ready for the rough plumbing inspection and another framing inspection, all the siding is on and the solar installation is next. PG&E is coming on March 28 to hook up the electrical. The trench is to run power from the new main panel on the garage to the house, the meter panel on the house is being replaced with a sub panel. One good thing about all the rain we have had, it was easy digging, The little room framed up inside is the bathroom.

jknaus

Administrator

Thats so cool. My Dad ran the first World RC Helicopter contest back in the early 70s and was the North American distributor for Schluter Helicopters until an unfortunate event. I miss RC helicopters but too expensive to get into now adays. Would love to go and watch a show though.We had our twelfth annual Helicopter Scale Masters this weekend at my club and I took way too many pictures. Many of these models are powered by gas turbine engines, the rest are electric. Nobody was flying an IC engine in in any of them. This is a pretty well attended event with people coming from as far as Germany and Chile.

I've put some pictures on my website, here is the link:

http://www.yolo.net/~jeaton/WDA/20220513hsm/20220513hsm.html

James

Wow, you mean you don't have to use the bushes??

jeaton01

Well-known member

Nope!Wow, you mean you don't have to use the bushes??

Steve Ski

Well-known member

Sweet, looks great, john. I was surprised to see actual plywood sheet on the walls, most have been using OSB due to cost over the past few years. Plywood is always the better choice, if affordable. My kid works at a plywood plant, $4/sheet for end runs, that's 3/4" 4x8 plywood with one minor blemish on each sheet. Oh dear, whatever will I do? HA!

Lots of potential for a space like that and its good to see it up and running so quickly. Ruck On!

Lots of potential for a space like that and its good to see it up and running so quickly. Ruck On!

jeaton01

Well-known member

Thanks, Steve. I don't do OSB no matter what. The plywood was pretty dear when I bought it, all right. 5/8 tongue and groove on the roof, 1/2 inch sheathing on the walls. The 2X8 roof joists were the real pain, all that was available was kiln dried, but in the end it was great to work with such nice wood.

Gator

Well-known member

Nice space John. Two weeks ago I pulled almost everything out of my storage building, cleaned and reorganized. Now I can walk in, get to stuff including kits and tools and not have to take anything out. I have a table saw and a compound miter saw, both on rolling stands that don't have to be moved unless I roll them out to use them. We bought a small 3 x 5 shed for the garden tools. Me and the pups put that together.