Trumpeter has been known to release kits of lesser-known vehicles which have appeared as resin kits. Several of these, such as Pit Road’s JGSDF IFV, and On Track Models’ 12,8cm Sf. have already appeared as kits with very good detail, fit, and finish. When Trumpeter announced their ‘Dicker Max’, Dragon announced theirs as well and the race was on to be the first to release the kit. Sadly, this kit shows the effects of rushing to production. While not credited, Mr. Lam, of On Track Models, provided assistance to the research and this kit supposedly is an improvement on the original On Track Models kit.

During 1938/39, Krupp announced that they had started on a design of a self-propelled 10,5cm K/ L/52 gun. The next year, the design was completed and a contract awarded to Krupp-Grusonwerk to produce two trial vehicles in armor. Completed in January of 1941, the vehicle was demonstrated to Hitler at the end of March and sent to the front. Arriving too late for its intended role as a Maginot Line bunker buster, it was on strength with Panzerjaeger-Abteilung (Sfl.) 521. One of the two vehicles was destroyed when its ammunition apparently blew up. Several photos were taken of it turned turtle in a barren area. Later photos show it abandoned by a road near a light wooden bridge in a wooded area. Was the recovery abandoned due to the light nature of the bridge?

What about the name ‘Dicker Max’? The unit’s commander, Oberleutnant Kurt Hildebrandt relates that the surviving 10.5cm Sf. was called Brummbär. (6) So where did 'Dicker Max' come from?

The Kit

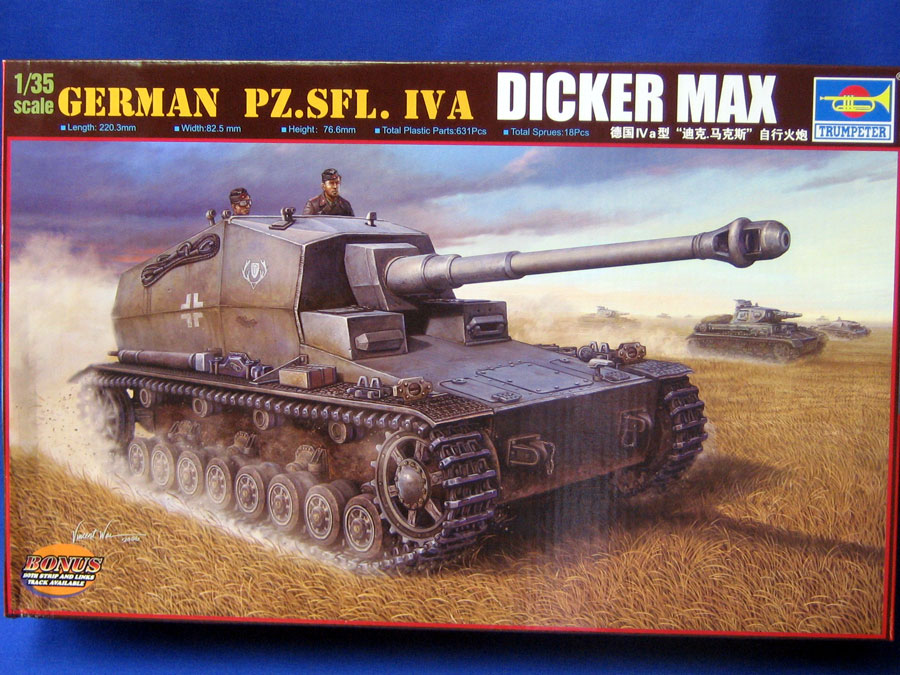

Box Art

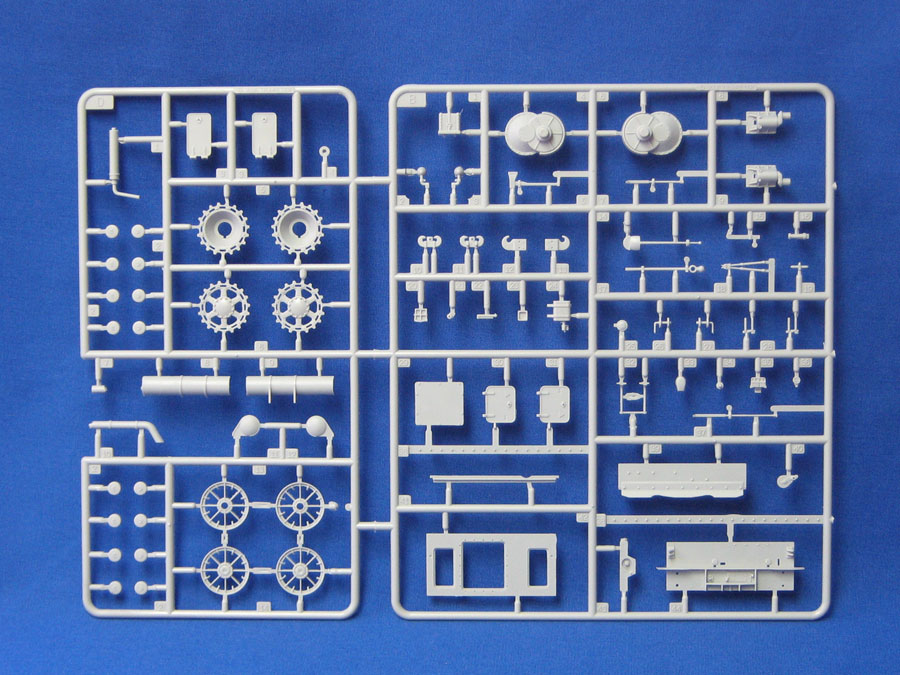

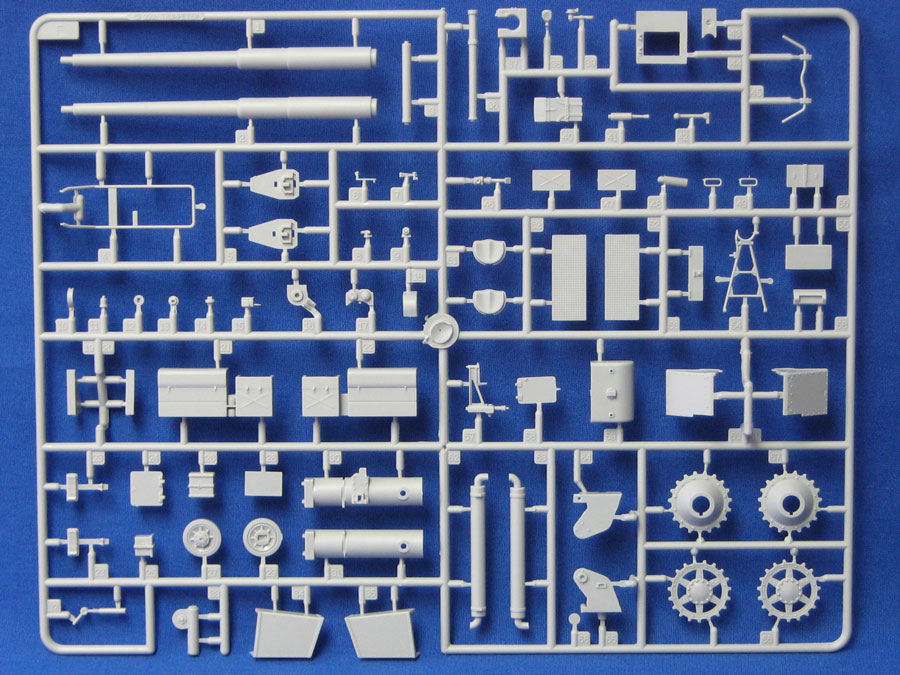

Sprue A

Sprue D

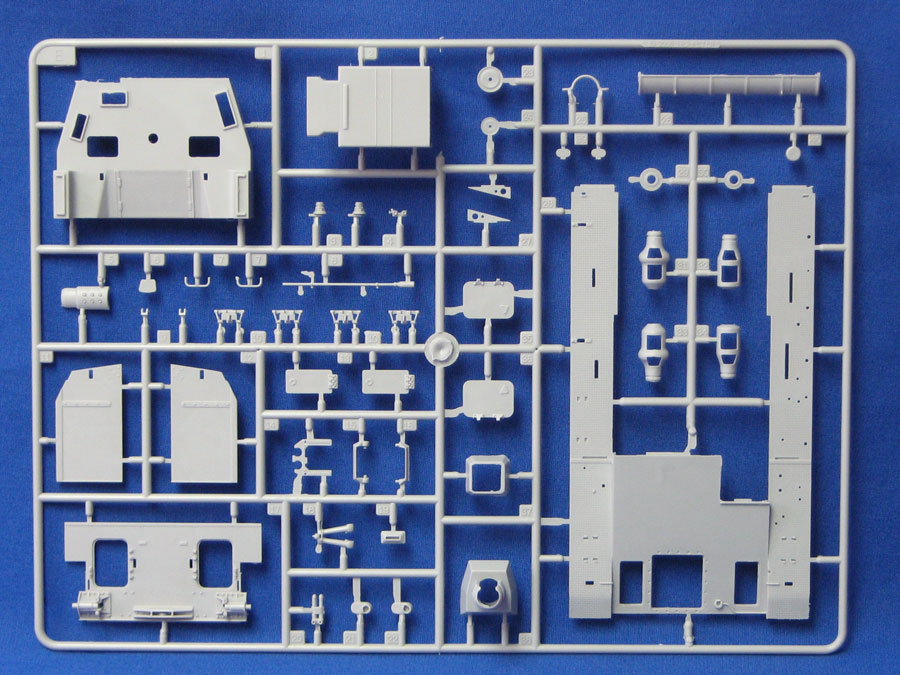

Sprue E new tool for Pz.Sfl. IVa

Sprue F new tool Pz.Sfl. IVa

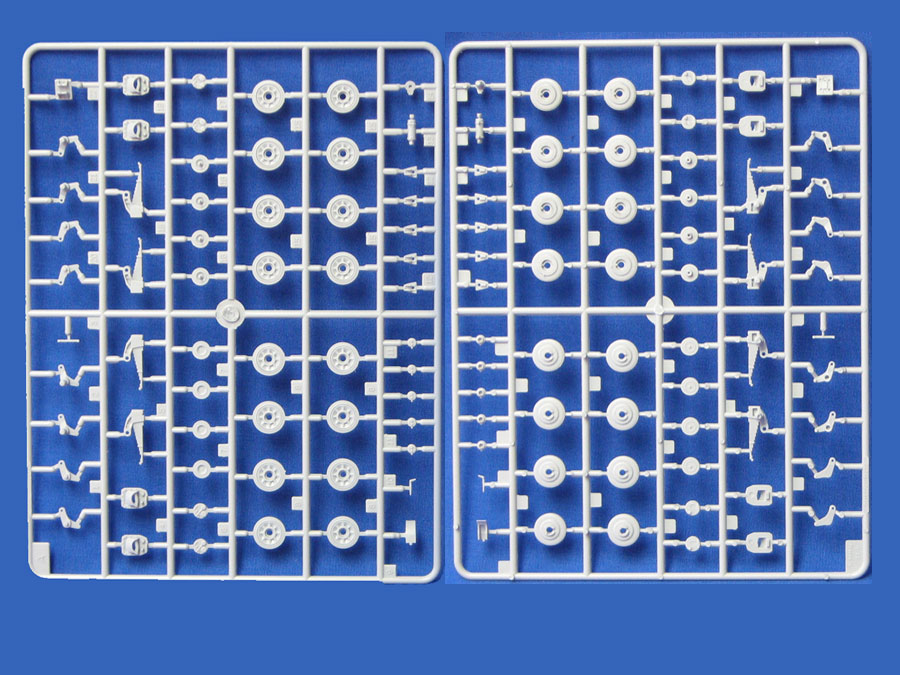

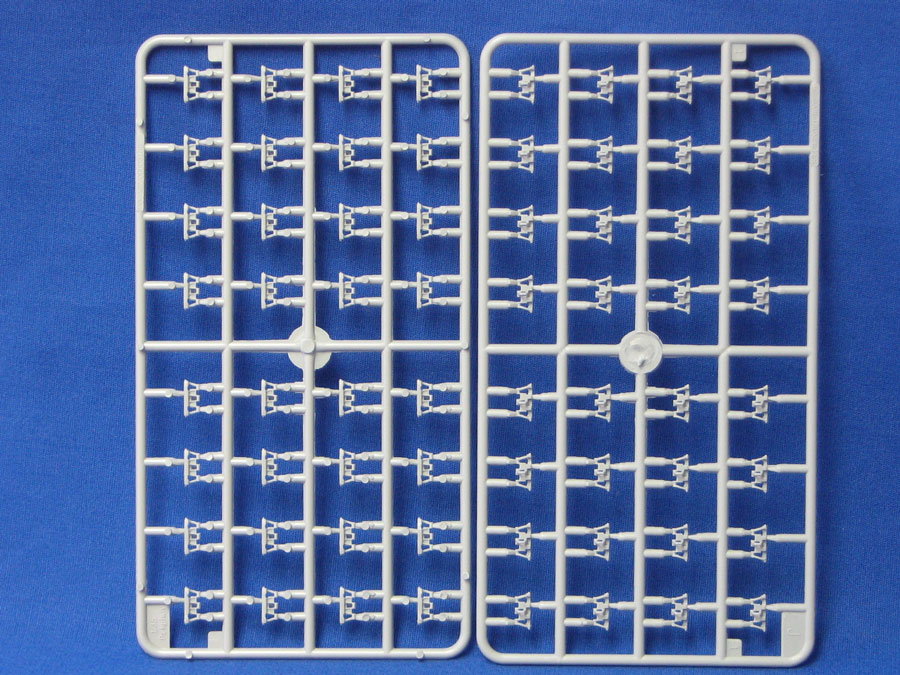

Sprue J 8 of these

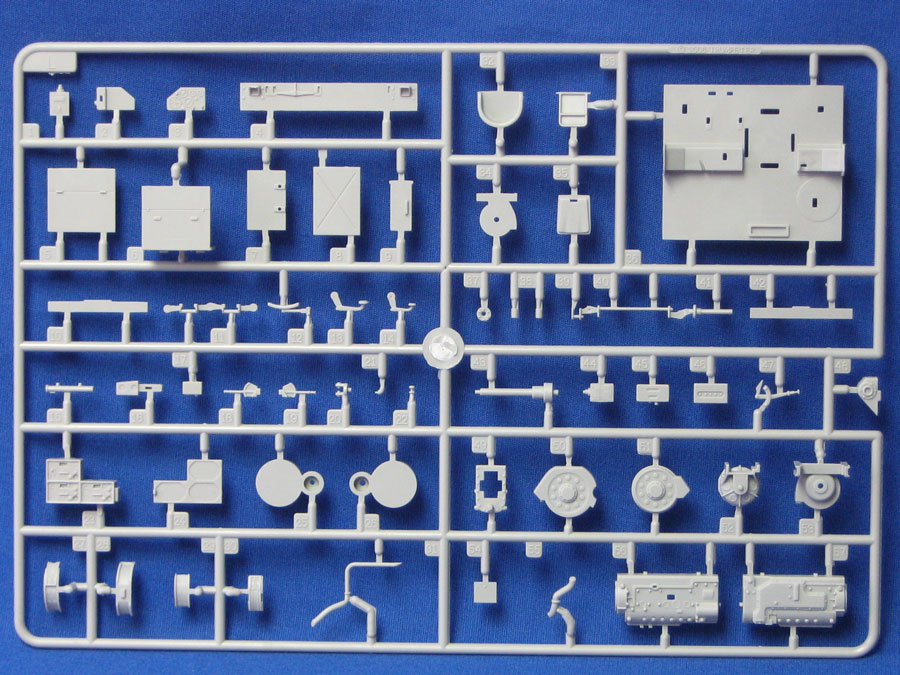

Sprue L new tool for Panzerkampfwagen IV interior

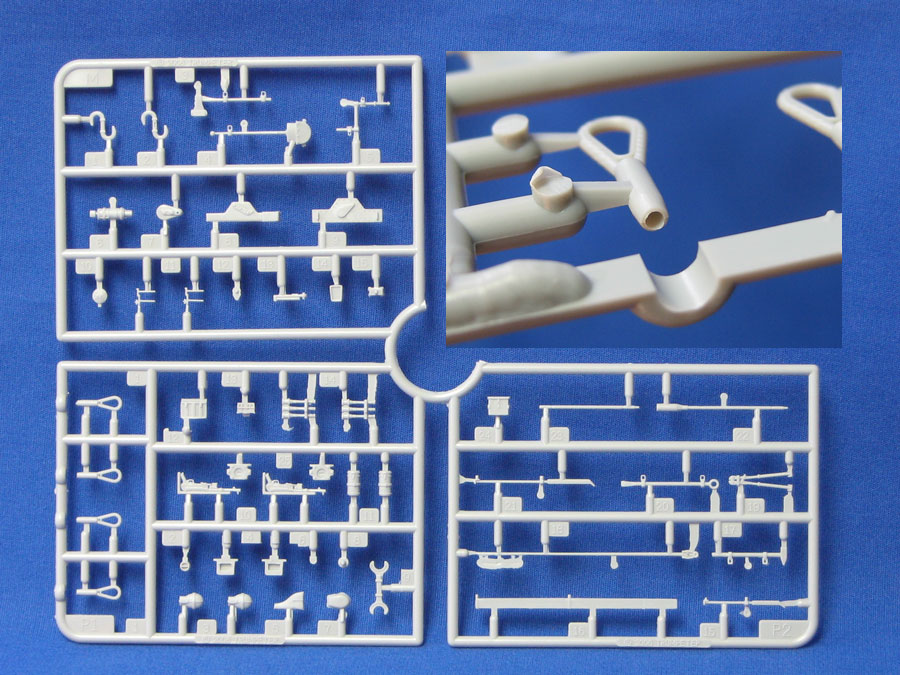

Sprues M, P1, P2

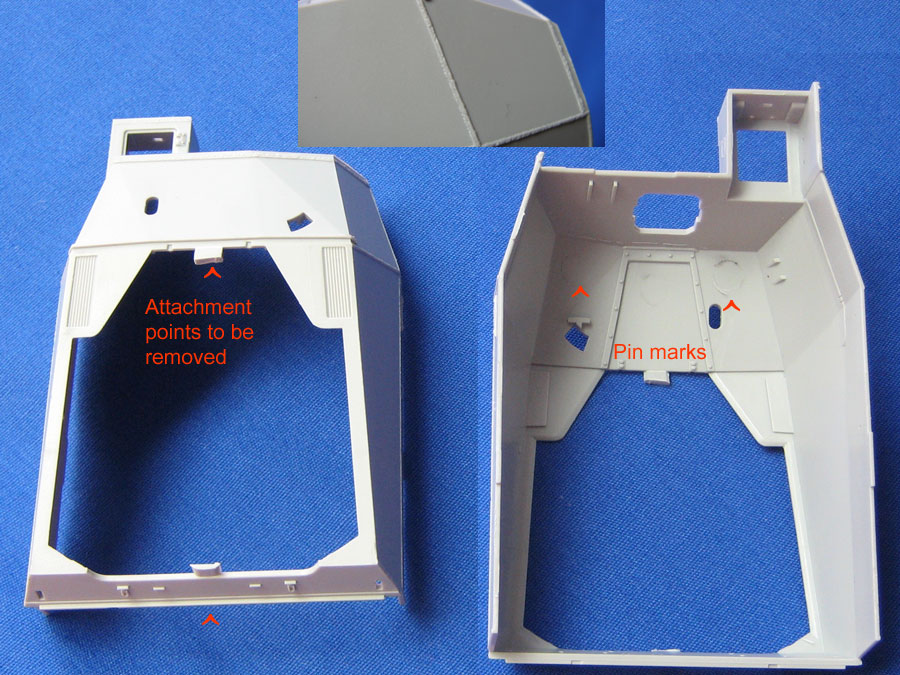

Upper Hull with some notes:

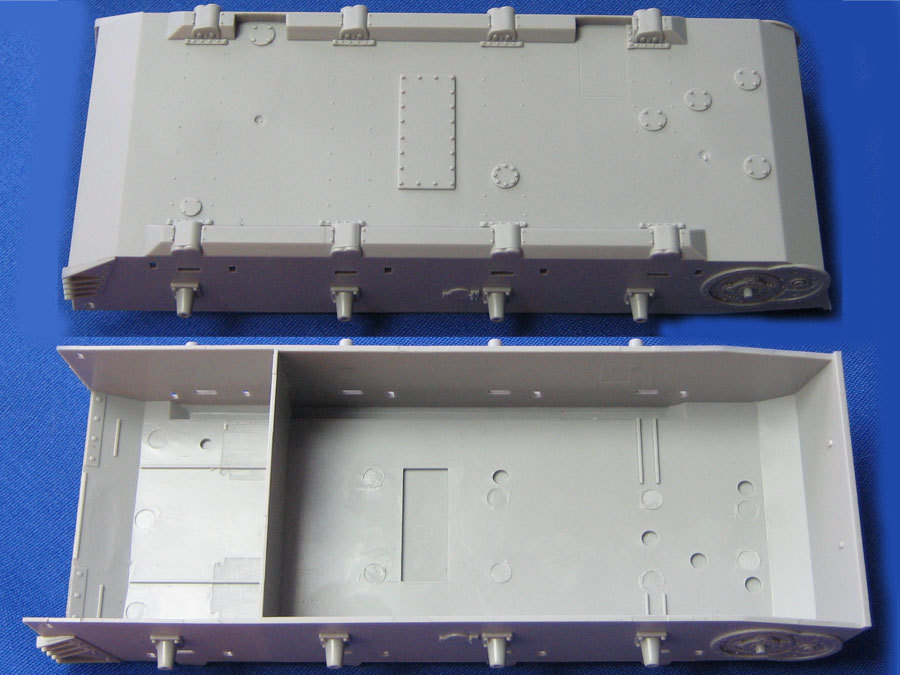

Lower Hull

Lower Hull

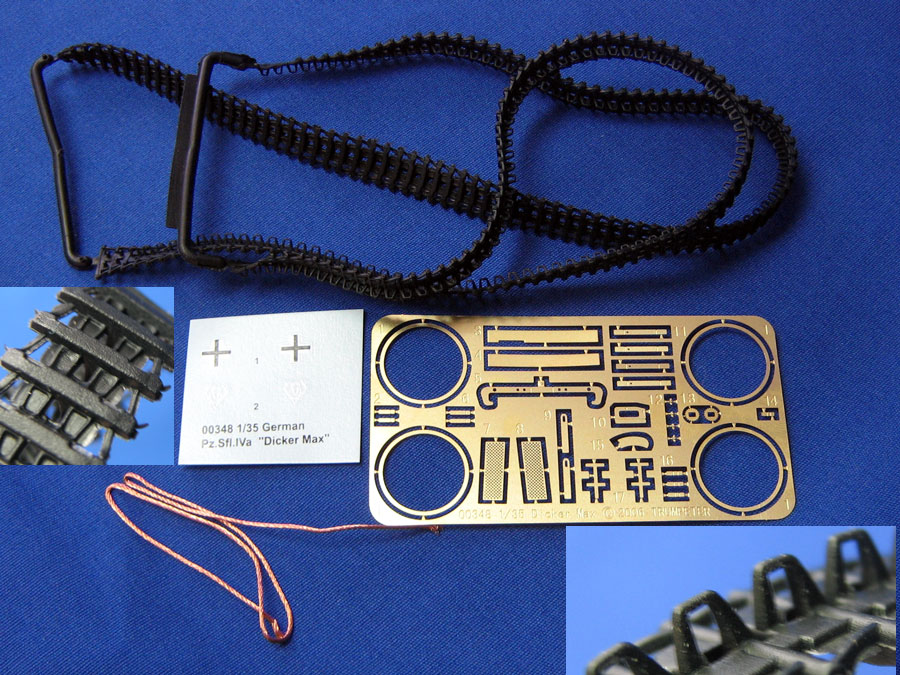

Accessories

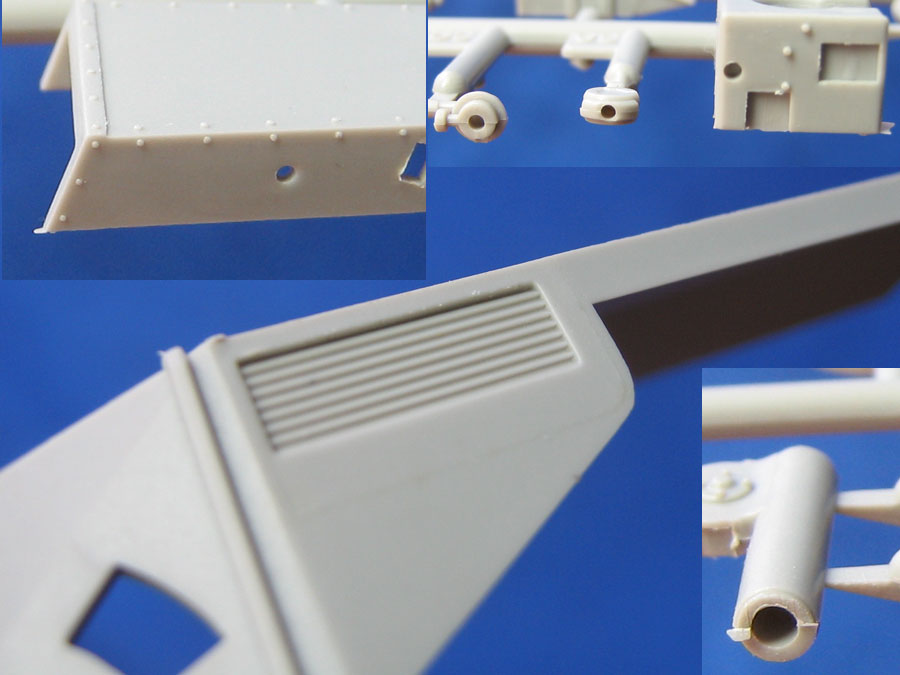

Close up of details, flash, & mismatched mold halves

Looking over the parts on the sprues, I was surprised at the amount of flash I encountered. These were limited to the newly tooled parts for the Pz.Sfl. Iva and not present on sprue D (from their Karl Munitionschlepper on Ausf. D chassis) or sprue L which signals a turreted panzer IV is in the works with a full interior. A light amount of flash appeared on the parts on sprue P which has appeared before.

The instructions cover the model’s assembly in 28 steps on twenty pages. As is usual, they are drawings only. A separate full color sheet, on glossy stock, covers painting and markings. Only one marking choice is provided but the unit, Pz.Jag.Abt. (Sfl.) 521, is not identified.

Step one covers the assembly of the road wheels (make 16, not sixth as written), idlers, and drive sprockets. Since I planned to concentrate my detailing efforts to the exterior, I did not attach the photo-etch lip to the idlers. There was a lot of small flash on the delicate fingers of the idler and I decided to cement each one carefully. Here is some play in the key/slot joint so I carefully rotated the idler halves until the best match was made. The PE parts only supply the outer lip but do not correct the cross section of the main spokes. Since these should be a zigzag cross section, I glued strips of 0.005 inch styrene. To ensure the correct alignment of the drive wheel halves, I used the poly-vinyl tracks as a jig by wrapping them around the toothed rings.

The next step, two, covered attaching the return rollers (make 8, not twelve as written), bump stops, and final drive covers. I left off parts A11, the actual bump stops, until later but did attach their mounts (A12) to the lower hull. I realized that the hinges for the fuel ports are incorrect and cut them off. I used a filler port cover from a spare Panzer IV hull to correct this. Also, Trumpeter has provided a modified belly pan in recognition of the changes from the mid-engine mount design. This includes different drain ports, a squared off cut out as an escape hatch, a small transversely mounted rectangular armor panel, and omission of brake drain panels. Sadly, these are all wrong when compared to the photos of the destroyed vehicle. The front tow connections (parts A22 & B26) were glued together, allowed to dry, then the retaining pin cut off, the parts sanded to eliminate the seam, a new hole drilled and a new retaining pin made from bent wire. If so inclined, attach a micro chain from the pin to the mount as per any other Panzer IV.

The third step is the Rear Panel assembly. It should be noted that the spare wheel outer half (part F27) has the correct hub cap. Not wanting to deal with the numerous pin marks in the interior, I glued the rear hatches (parts E35 and E36) in the closed position. I recommend leaving off parts E21 and E22, the idler mounting arms, off until positioning the tracks to ensure the correct tension. I was not happy with the way the trailer hitch looked so I drilled through the plates and made my own retaining pin from bent wire.

Steps four and five covers attaching the rear fighting compartment wall, drive wheels, fighting compartment sidewalls (in step 4), tow hooks (in step 5), and the road wheel bogies. First, fill in the hollow area of the idler mount on the rear fighting compartment wall. A dry fit to the lower hull will show that the hollow area is visible and would be difficult to fill after gluing the rear wall in place. I recommend attaching the tow hooks, parts B12 and B13, before attaching the fighting compartment sidewalls (parts E11 & E12). This will help in preventing the half circular mounting tab from interfering with the sidewall fit since one can trim it after the glue cures. While the bogie caps, parts A6 & A17, are correct for this vehicle, the bogie leaf springs should have an end cap which is not present. I’ll take mine from the Panzer IV kit which I am using as a hangar queen.

From step six to step eight, the suspension is completed. Road wheels, idlers, and tracks are added. There is a choice of polystyrene/vinyl tracks or individual link polystyrene tracks. The flexible tracks can be glued with normal plastic model cement but suffer from flash. There are 256 individual plastic links of which a few suffer from flash and pin marks but they are well done with smooth faces and hollow guide teeth.

The panzer IV interior is covered in steps nine through thirteen. Here, we find a nicely done Z.F. SSG 76 transmission, driving compartment floor with a round escape hatch, driver’ seat, radio operator’s seat, drive shafts, pedals, steering levers, brakes, instrument cluster, radio set, communications equipment (and ammunition boxes which are marked ‘not for use’). This is all sharply molded and well done for a panzer IV but the Pz. Sfl. IVa used a visibly smaller Z.F. SSG 46 transmission and the RO position was not used. The RO ‘box’ on the glacis plate was most probably a storage box and did not open into the hull. It is similar to that which appeared on the 12.8cm Sf. which was removed in the field. Since I have made up my mind to put the fighting compartment under a tarp, I will use this interior for another kit. I am certain it will be a perfect fit to Trumpeter’s other Panzer IV based offerings. Checking the fit later on, I noticed that the driving compartment interior is not really visible in the end.

Three steps, 14 through 16, cover lower hull details and adding the glacis/fender part E 28. Make sure to open the locating slots for the storage box and gun travel lock is using them. The latter appeared as the Pz. Sfl. IVa went to the field along with a lighter muzzle brake. The tread pattern on the fenders is of the herring bone type seen on panzer IV tanks. Strangely enough, the factory photos in the first reference listed show a large dot pattern on the right and the herringbone on the left! The radiator air exhaust duct, part E2, does not have any filler ports, fasteners, weld seams, or indication of its function. The forward wall to which it attaches has a mold seam to remove and no other details to indicate that an engine is located there. A view through the right rear door seems to indicate that there should be an access plate and wooden slats on the floor. Instead, Trumpeter provides tread plate, parts F52, which attach to the floor. All photos of Panzer IV vehicles show a duct running from the left bogie mount to the right (as provided in the driving compartment floor plate). So, should the wooden slats rest on this duct?

The gun, mount, and fighting compartment floor are covered in steps 17 through 19. A tremendous amount of well-done detail is included which is sadly marred by flash and pin marks. After assembly, the gun does track to the left and right. In preparation to show the vehicle in transit with a tarp, I left off the periscope, part F46, which would normally protrude from the roof of the superstructure.

Steps 20 and 21 cover the upper fighting compartment armor and the storage box. I recommend jumping to step 22 and attaching the collar, part E37, before attaching the upper compartment, called Turret Hull, to the chassis. This is because the mounting tabs are visible on the inside and to make adding weld marks easier since none are depicted. While you’re at it, remove and redo the weld seams which are present as they are too proud and too wide. I glued the driver’s hatch (part F24) shut. The driver’s visor armor flap (part E15) can be mounted open or closed. There are photo etched screens to mount on the engine inlet ducts but I have not seen a photo to indicate this as being correct or not.

The next five steps (22-26) cover external tools, engine exhaust pipe, tow cables (twisted copper wire with plastic eyes), gun tube, gun mantlet, and ammunition boxes (closed state). Difficult to remove pin marks appear inside of the stowage tray (part E26). Canteens should also mount on the forward-facing sides of the air inlet trunks but are not provided. As I had decided not to mount the scissors scope (part E20), I closed its hatch, part E6.

The last two steps cover the alternate schemes. Step 27 is for the initial version as it appears in factory photos while the last is in the field with the gun travel lock and lightweight muzzle brake. In each case, it is a two-part muzzle brake with a long seam and an inner grommet plate.

Summary

Had Trumpeter taken its time to clean up the molds, another nice kit would have resulted. The detail is good with the only visible error being the fuel filler port hinges. The belly pan bothers me but most modelers I have spoken to don’t care. Yet, what we end up with is a lot of flash and pin marks that could have been avoided.

This flash does get in the way of the mating surfaces so care should be taken when removing it. Fortunately, the plastic is easy to work with but there are also numerous pin marks to fill in, some with flash making matters worse. To top it off, the rear air exhaust, part F59, has tabs that fit into slots on the upper rear fighting compartment wall. The end result of the tabs in the slots is very visible and calls for filling and sanding in very close proximity to detail. I have decided not to bother filling in any of the pin marks or slots and just concentrate on the exterior. A tarp will be fashioned for the fighting compartment saving me a lot of work.

My thanks got to Trumpeter’s US distributor, Stevens International, for the review sample.

References

Panzer Tracts 7-1 Panzer jaeger (3.7 cm Tak to Pz.Sfl.Ic) development and employment from 1927 to 1941 by Thomas L. Jentz and Hilary L Doyle

Panzer IV and its Variants by Walter J. Spielberger

Allied-Axis Magazine number 17

Panzer vor! 4 by Frank V. DeSisto

The Combat History of schwere Panzerjäger Abteilung 654 by Karlheinz Munch

Panzer Tracts No. 7-3 Panzerjäger (7.5cm Pak 40/4 to 8.8cm Waffenträger) development and employment from 1939 to 1945 by Thomas L. Jentz and Hilary L Doyle

© Apr 24, 2007 by Saul Garcia

During 1938/39, Krupp announced that they had started on a design of a self-propelled 10,5cm K/ L/52 gun. The next year, the design was completed and a contract awarded to Krupp-Grusonwerk to produce two trial vehicles in armor. Completed in January of 1941, the vehicle was demonstrated to Hitler at the end of March and sent to the front. Arriving too late for its intended role as a Maginot Line bunker buster, it was on strength with Panzerjaeger-Abteilung (Sfl.) 521. One of the two vehicles was destroyed when its ammunition apparently blew up. Several photos were taken of it turned turtle in a barren area. Later photos show it abandoned by a road near a light wooden bridge in a wooded area. Was the recovery abandoned due to the light nature of the bridge?

What about the name ‘Dicker Max’? The unit’s commander, Oberleutnant Kurt Hildebrandt relates that the surviving 10.5cm Sf. was called Brummbär. (6) So where did 'Dicker Max' come from?

The Kit

Box Art

Sprue A

Sprue D

Sprue E new tool for Pz.Sfl. IVa

Sprue F new tool Pz.Sfl. IVa

Sprue J 8 of these

Sprue L new tool for Panzerkampfwagen IV interior

Sprues M, P1, P2

Upper Hull with some notes:

Accessories

Close up of details, flash, & mismatched mold halves

Looking over the parts on the sprues, I was surprised at the amount of flash I encountered. These were limited to the newly tooled parts for the Pz.Sfl. Iva and not present on sprue D (from their Karl Munitionschlepper on Ausf. D chassis) or sprue L which signals a turreted panzer IV is in the works with a full interior. A light amount of flash appeared on the parts on sprue P which has appeared before.

The instructions cover the model’s assembly in 28 steps on twenty pages. As is usual, they are drawings only. A separate full color sheet, on glossy stock, covers painting and markings. Only one marking choice is provided but the unit, Pz.Jag.Abt. (Sfl.) 521, is not identified.

Step one covers the assembly of the road wheels (make 16, not sixth as written), idlers, and drive sprockets. Since I planned to concentrate my detailing efforts to the exterior, I did not attach the photo-etch lip to the idlers. There was a lot of small flash on the delicate fingers of the idler and I decided to cement each one carefully. Here is some play in the key/slot joint so I carefully rotated the idler halves until the best match was made. The PE parts only supply the outer lip but do not correct the cross section of the main spokes. Since these should be a zigzag cross section, I glued strips of 0.005 inch styrene. To ensure the correct alignment of the drive wheel halves, I used the poly-vinyl tracks as a jig by wrapping them around the toothed rings.

The next step, two, covered attaching the return rollers (make 8, not twelve as written), bump stops, and final drive covers. I left off parts A11, the actual bump stops, until later but did attach their mounts (A12) to the lower hull. I realized that the hinges for the fuel ports are incorrect and cut them off. I used a filler port cover from a spare Panzer IV hull to correct this. Also, Trumpeter has provided a modified belly pan in recognition of the changes from the mid-engine mount design. This includes different drain ports, a squared off cut out as an escape hatch, a small transversely mounted rectangular armor panel, and omission of brake drain panels. Sadly, these are all wrong when compared to the photos of the destroyed vehicle. The front tow connections (parts A22 & B26) were glued together, allowed to dry, then the retaining pin cut off, the parts sanded to eliminate the seam, a new hole drilled and a new retaining pin made from bent wire. If so inclined, attach a micro chain from the pin to the mount as per any other Panzer IV.

The third step is the Rear Panel assembly. It should be noted that the spare wheel outer half (part F27) has the correct hub cap. Not wanting to deal with the numerous pin marks in the interior, I glued the rear hatches (parts E35 and E36) in the closed position. I recommend leaving off parts E21 and E22, the idler mounting arms, off until positioning the tracks to ensure the correct tension. I was not happy with the way the trailer hitch looked so I drilled through the plates and made my own retaining pin from bent wire.

Steps four and five covers attaching the rear fighting compartment wall, drive wheels, fighting compartment sidewalls (in step 4), tow hooks (in step 5), and the road wheel bogies. First, fill in the hollow area of the idler mount on the rear fighting compartment wall. A dry fit to the lower hull will show that the hollow area is visible and would be difficult to fill after gluing the rear wall in place. I recommend attaching the tow hooks, parts B12 and B13, before attaching the fighting compartment sidewalls (parts E11 & E12). This will help in preventing the half circular mounting tab from interfering with the sidewall fit since one can trim it after the glue cures. While the bogie caps, parts A6 & A17, are correct for this vehicle, the bogie leaf springs should have an end cap which is not present. I’ll take mine from the Panzer IV kit which I am using as a hangar queen.

From step six to step eight, the suspension is completed. Road wheels, idlers, and tracks are added. There is a choice of polystyrene/vinyl tracks or individual link polystyrene tracks. The flexible tracks can be glued with normal plastic model cement but suffer from flash. There are 256 individual plastic links of which a few suffer from flash and pin marks but they are well done with smooth faces and hollow guide teeth.

The panzer IV interior is covered in steps nine through thirteen. Here, we find a nicely done Z.F. SSG 76 transmission, driving compartment floor with a round escape hatch, driver’ seat, radio operator’s seat, drive shafts, pedals, steering levers, brakes, instrument cluster, radio set, communications equipment (and ammunition boxes which are marked ‘not for use’). This is all sharply molded and well done for a panzer IV but the Pz. Sfl. IVa used a visibly smaller Z.F. SSG 46 transmission and the RO position was not used. The RO ‘box’ on the glacis plate was most probably a storage box and did not open into the hull. It is similar to that which appeared on the 12.8cm Sf. which was removed in the field. Since I have made up my mind to put the fighting compartment under a tarp, I will use this interior for another kit. I am certain it will be a perfect fit to Trumpeter’s other Panzer IV based offerings. Checking the fit later on, I noticed that the driving compartment interior is not really visible in the end.

Three steps, 14 through 16, cover lower hull details and adding the glacis/fender part E 28. Make sure to open the locating slots for the storage box and gun travel lock is using them. The latter appeared as the Pz. Sfl. IVa went to the field along with a lighter muzzle brake. The tread pattern on the fenders is of the herring bone type seen on panzer IV tanks. Strangely enough, the factory photos in the first reference listed show a large dot pattern on the right and the herringbone on the left! The radiator air exhaust duct, part E2, does not have any filler ports, fasteners, weld seams, or indication of its function. The forward wall to which it attaches has a mold seam to remove and no other details to indicate that an engine is located there. A view through the right rear door seems to indicate that there should be an access plate and wooden slats on the floor. Instead, Trumpeter provides tread plate, parts F52, which attach to the floor. All photos of Panzer IV vehicles show a duct running from the left bogie mount to the right (as provided in the driving compartment floor plate). So, should the wooden slats rest on this duct?

The gun, mount, and fighting compartment floor are covered in steps 17 through 19. A tremendous amount of well-done detail is included which is sadly marred by flash and pin marks. After assembly, the gun does track to the left and right. In preparation to show the vehicle in transit with a tarp, I left off the periscope, part F46, which would normally protrude from the roof of the superstructure.

Steps 20 and 21 cover the upper fighting compartment armor and the storage box. I recommend jumping to step 22 and attaching the collar, part E37, before attaching the upper compartment, called Turret Hull, to the chassis. This is because the mounting tabs are visible on the inside and to make adding weld marks easier since none are depicted. While you’re at it, remove and redo the weld seams which are present as they are too proud and too wide. I glued the driver’s hatch (part F24) shut. The driver’s visor armor flap (part E15) can be mounted open or closed. There are photo etched screens to mount on the engine inlet ducts but I have not seen a photo to indicate this as being correct or not.

The next five steps (22-26) cover external tools, engine exhaust pipe, tow cables (twisted copper wire with plastic eyes), gun tube, gun mantlet, and ammunition boxes (closed state). Difficult to remove pin marks appear inside of the stowage tray (part E26). Canteens should also mount on the forward-facing sides of the air inlet trunks but are not provided. As I had decided not to mount the scissors scope (part E20), I closed its hatch, part E6.

The last two steps cover the alternate schemes. Step 27 is for the initial version as it appears in factory photos while the last is in the field with the gun travel lock and lightweight muzzle brake. In each case, it is a two-part muzzle brake with a long seam and an inner grommet plate.

Summary

Had Trumpeter taken its time to clean up the molds, another nice kit would have resulted. The detail is good with the only visible error being the fuel filler port hinges. The belly pan bothers me but most modelers I have spoken to don’t care. Yet, what we end up with is a lot of flash and pin marks that could have been avoided.

This flash does get in the way of the mating surfaces so care should be taken when removing it. Fortunately, the plastic is easy to work with but there are also numerous pin marks to fill in, some with flash making matters worse. To top it off, the rear air exhaust, part F59, has tabs that fit into slots on the upper rear fighting compartment wall. The end result of the tabs in the slots is very visible and calls for filling and sanding in very close proximity to detail. I have decided not to bother filling in any of the pin marks or slots and just concentrate on the exterior. A tarp will be fashioned for the fighting compartment saving me a lot of work.

My thanks got to Trumpeter’s US distributor, Stevens International, for the review sample.

References

Panzer Tracts 7-1 Panzer jaeger (3.7 cm Tak to Pz.Sfl.Ic) development and employment from 1927 to 1941 by Thomas L. Jentz and Hilary L Doyle

Panzer IV and its Variants by Walter J. Spielberger

Allied-Axis Magazine number 17

Panzer vor! 4 by Frank V. DeSisto

The Combat History of schwere Panzerjäger Abteilung 654 by Karlheinz Munch

Panzer Tracts No. 7-3 Panzerjäger (7.5cm Pak 40/4 to 8.8cm Waffenträger) development and employment from 1939 to 1945 by Thomas L. Jentz and Hilary L Doyle

© Apr 24, 2007 by Saul Garcia