As others have stated, it comes down to quality tools and the knowledge to use them. Invest in quality tools and practice with them. Until my wife swiped them away, I had Tweezerman tweezers and scissors (to cut PE free), and Wilder (as in Adam Wilder) tweezers.

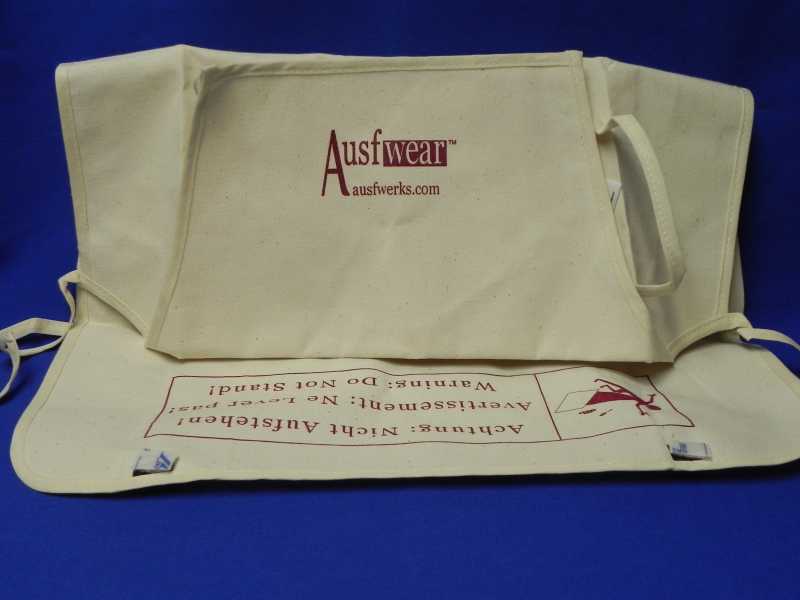

What I use now are a set of Swiss tweezers I bought off eBay, Xuron PE scissors, a range of PE benders from The Small Shop, a superb bending brake (appropriately named The Fender Bender) from Ausfwerks [now OOP], and use various adhesives.

If the item to e glued is light with no stress on bare plastic, I have used Tamiya Thin Cement (green cap) to attach PE whose contact surface was roughed up with some sandpaper. If the items are painted, Gator's Grip Hobby Glue is perfect as it is tacky and one can remove the excess with water. note that now Kenny Loup, the man behind Gator's Grip Hobby Glue now offers two viscosities.

If items may come under some stress, then I decide if I should solder or cement. CA cement has poor shear strength, in those cases I use tiny dots of epoxy cement (a wasteful exercise as the amount mixed is always greater than actually used).

For soldering, I have several options. Obviously, I only use this to attach similar metals. Sometimes one must solder items real close to each other so I suggest looking at Chukw's SBS but one he hasn't shown is using high and low temperature solder. I use the high temperature solder on parts skipping items in between which I come back to with low temperature solder since it won't affect the high temperature (I use Tix brand) soldered joints.

For soldering, I have a Cold Heat product (sold in Radio Shack) for low temperature, a Wahl cordless soldering iron, or my American Beauty (thanks Ausf) resistance soldering set.

Regards,

What I use now are a set of Swiss tweezers I bought off eBay, Xuron PE scissors, a range of PE benders from The Small Shop, a superb bending brake (appropriately named The Fender Bender) from Ausfwerks [now OOP], and use various adhesives.

If the item to e glued is light with no stress on bare plastic, I have used Tamiya Thin Cement (green cap) to attach PE whose contact surface was roughed up with some sandpaper. If the items are painted, Gator's Grip Hobby Glue is perfect as it is tacky and one can remove the excess with water. note that now Kenny Loup, the man behind Gator's Grip Hobby Glue now offers two viscosities.

If items may come under some stress, then I decide if I should solder or cement. CA cement has poor shear strength, in those cases I use tiny dots of epoxy cement (a wasteful exercise as the amount mixed is always greater than actually used).

For soldering, I have several options. Obviously, I only use this to attach similar metals. Sometimes one must solder items real close to each other so I suggest looking at Chukw's SBS but one he hasn't shown is using high and low temperature solder. I use the high temperature solder on parts skipping items in between which I come back to with low temperature solder since it won't affect the high temperature (I use Tix brand) soldered joints.

For soldering, I have a Cold Heat product (sold in Radio Shack) for low temperature, a Wahl cordless soldering iron, or my American Beauty (thanks Ausf) resistance soldering set.

Regards,