Nick_Karatzides

Member

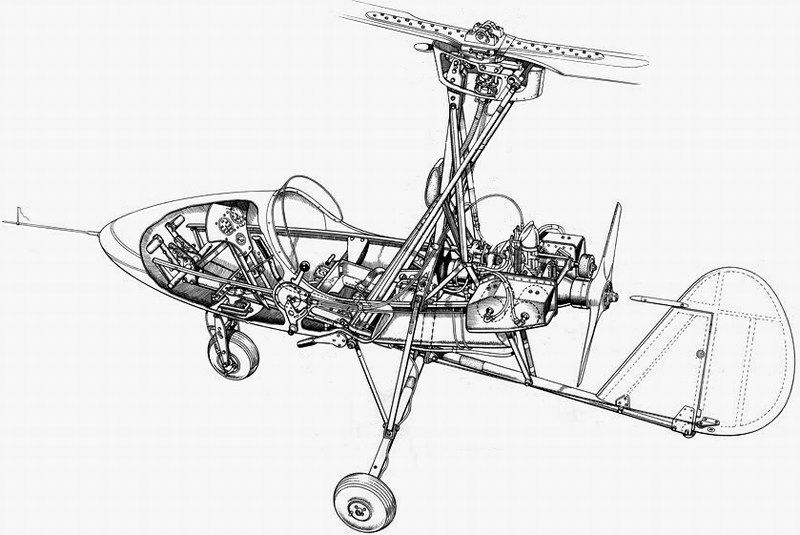

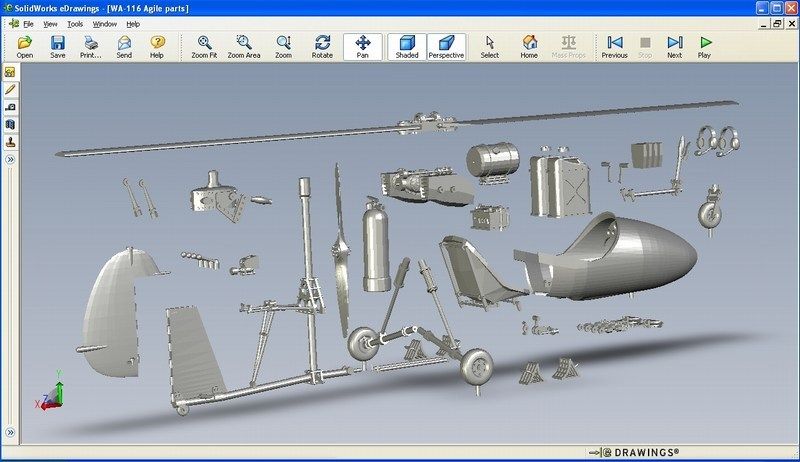

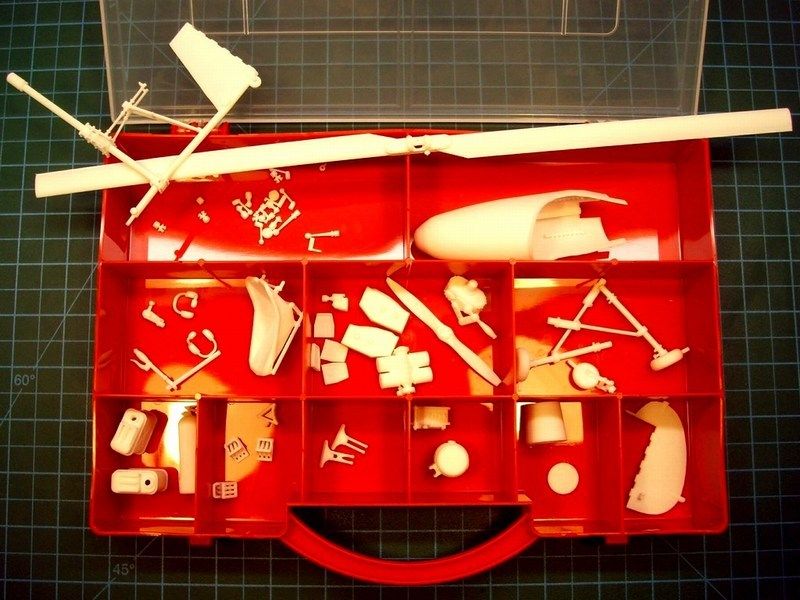

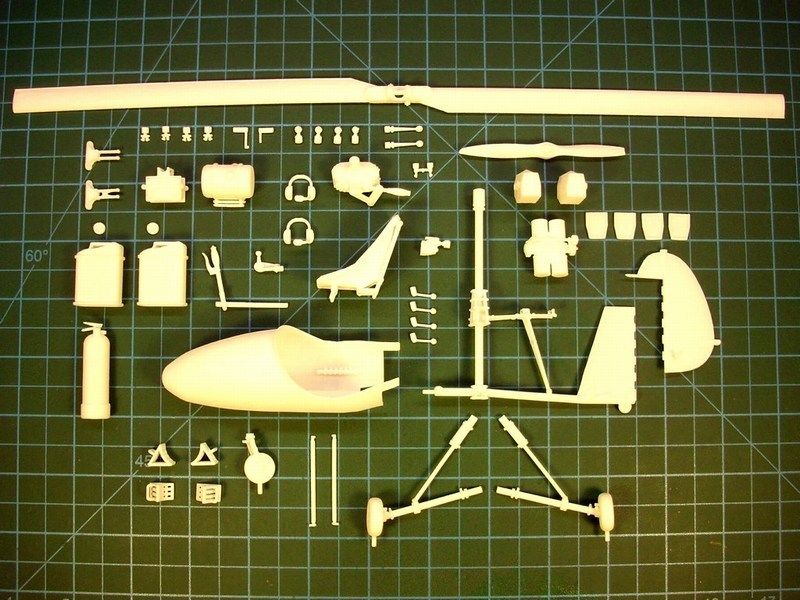

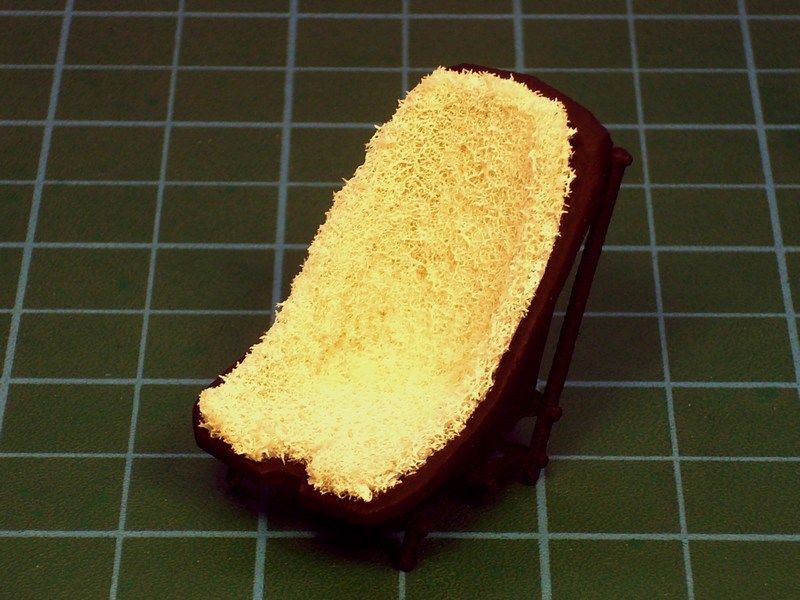

1/18 scale Wallis WA-116 Agile autogyro scratchbuild model

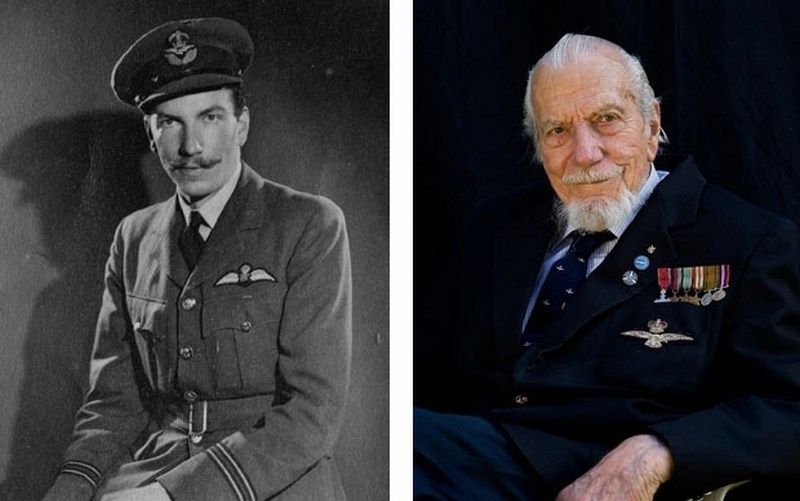

The following construction is a tribute to RAF Wing Commander Kenneth Horatio Wallis DSO MBE CEng FRAeS PhD, a pioneer gyrocopter aviator, who passed away early on Sunday morning, September 1st 2013. Ken was 97 years old. During the WWII, Wallis served in the Royal Air Force as Westland Lysander and Wellington pilot and flew 28 bomber missions over Germany. After the War, he flew the massive Convair B-36 and later involved in research and development, before retiring in 1964. He later became one of the leading exponents of autogyros and earned 34 world records, still holding eight of them at the time of his death. He was an inspiration to us all and we shall greatly miss him. A local hero and a national treasure.

He was born on the 26th April 1916, at Ely in Cambridgeshire. With his father and uncle having built an aeroplane in 1908 to fly the channel in a competition that was eventually won by Louis Bleriot, Ken Wallis acquired an interest in practical mechanics at an early age and by the time he was eleven years old had built his own motorcycle. He eventually turned his attention to aviation following a flying demonstration he watched in 1936 of the Henri Mignet HM-14 Flying Flea / Pou Du Ciel.

Ken will be greatly missed by the Flixton museum members. He was a frequent visitor, generous fundraiser and a great ambassador. In addition to the numerous professional institutions who welcomed Ken as a member and the vast number of clubs who regarded him with great respect and fondness, many ordinary people will also feel a loss in one way or another. Even a short chat with him left the individual feeling that it was something special and his warmth made them feel that he would remember them! Ken was recognised wherever he went. Admirers would soon gather and he would usually produce a small clipboard from a pocket, to sign and give away autographed postcards of him flying the “Little Nellie”. I am sure that many a childless adult has asked for a card to give to their “offspring”. Ken was inspirational, a great role model and possessed a rare old-world charm plus the impeccable manners of his age; all without a hint of grandeur. I am not alone in thinking that he was probably the grandfather figure we would all have liked to have had at some time. Norfolk was Ken’s home from 1963 and I venture to think he was appreciated by such a large part of its population that he was likely a close second to its most revered inhabitant: Horatio Nelson.

Goodbye Ken - our gyrocopter aviation hero and national treasure.