Iron Mike

Master At Arms And Resident Curmudgeon

I'll remember you saying that, you know.

Modelers Alliance has updated the forum software on our website. We have migrated all post, content and user accounts but we could not migrate the passwords.

This requires that you manually reset your password.

Please click here, http://modelersalliance.org/forums/login to go to logon page and use the "Forgot your Password" option.

So far so good Bob!

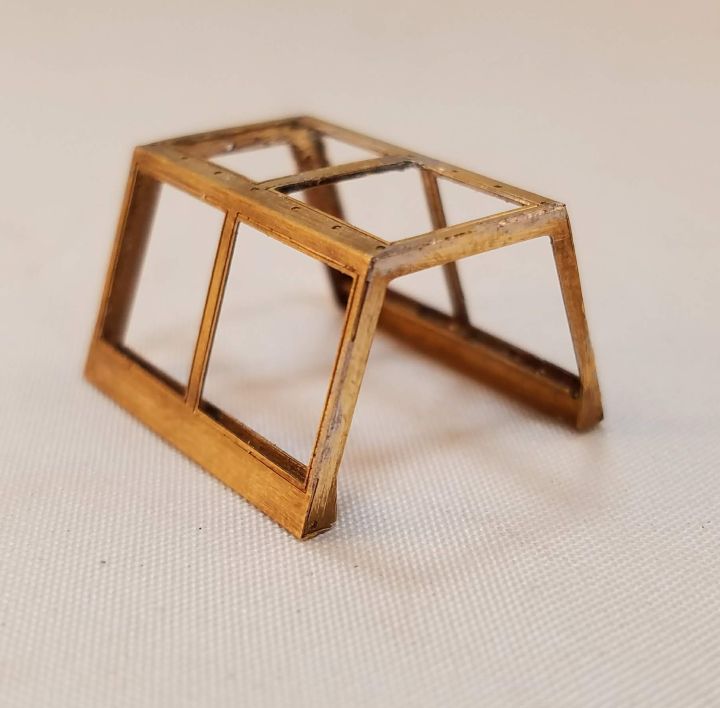

I would make a soldering suggestion. If you are joining 2 pieces at the edge, flux and pre-tin the edges. You don't need a lot of solder, just make them silver.

Then to join the pieces You can set them together and tack a couple of spots to hold it. The pre-tin will flow quickly when touched by a small drop of melted solder on the iron. Once it is tacked to your satisfaction, just run the iron slowly along the joint and it will bond along the whole joint without a lot of solder needing to be added.

Well I'm not exactly sure what's going on with this stuff.

I pealed back the film and about 90% of the rivets transferred. I played around with it a bit, the intent is to put these on, paint then sand back a bit. I put another layer of primer on and they disappear completely. Haven't tested with paint yet, suspect it will not disappear right away. Problem is I tend to be a heavy painter, lots of coats. I'm not sure if these are supposed to be chipped rivets or slightly raised. Not seeing this stuff used on a build before I'm not really sure what the end game is supposed to be.

I'm going to press forward.

BTW, they seem to react better sticking wise to Mr. Surfacer 1000 sanded with 4000 as opposed to Tamiya primer.

- never seen these used before.

- never seen these used before.Solder work is looking good Bob. I need to practice a lot more.

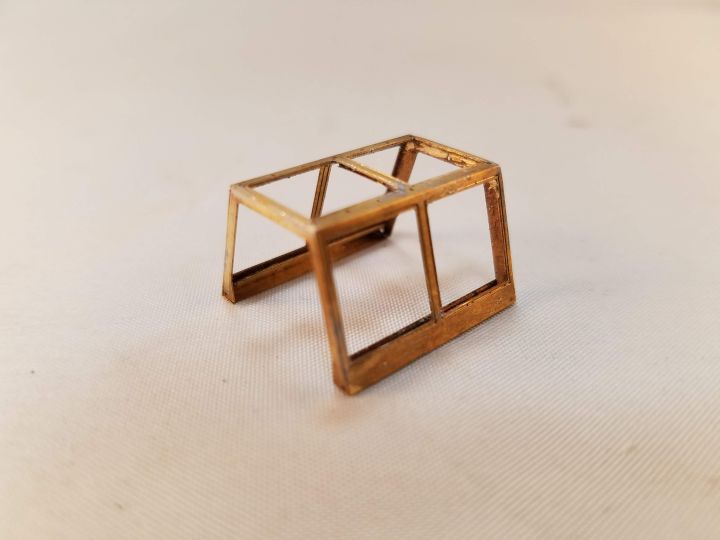

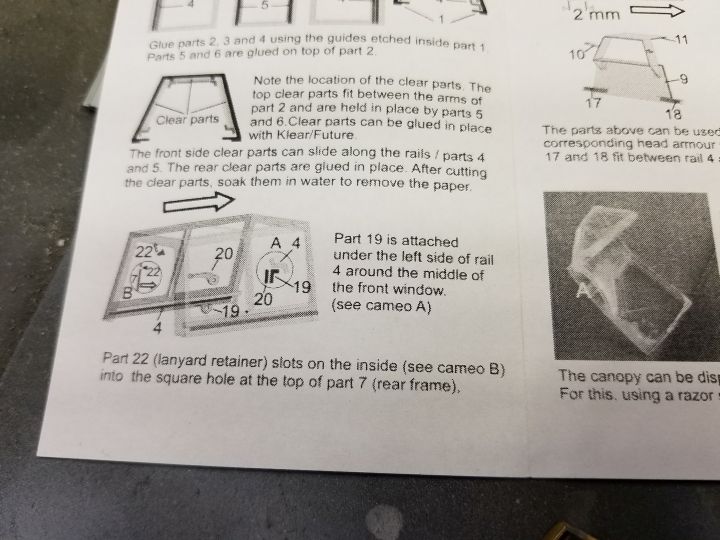

So I'm confused, what exactly is that etched piece? Canopy frame?

Mike

:hmmm :hmmm- never seen these used before.

So far so good Bob!

I would make a soldering suggestion. If you are joining 2 pieces at the edge, flux and pre-tin the edges. You don't need a lot of solder, just make them silver.

Then to join the pieces You can set them together and tack a couple of spots to hold it. The pre-tin will flow quickly when touched by a small drop of melted solder on the iron. Once it is tacked to your satisfaction, just run the iron slowly along the joint and it will bond along the whole joint without a lot of solder needing to be added.