Gator

Well-known member

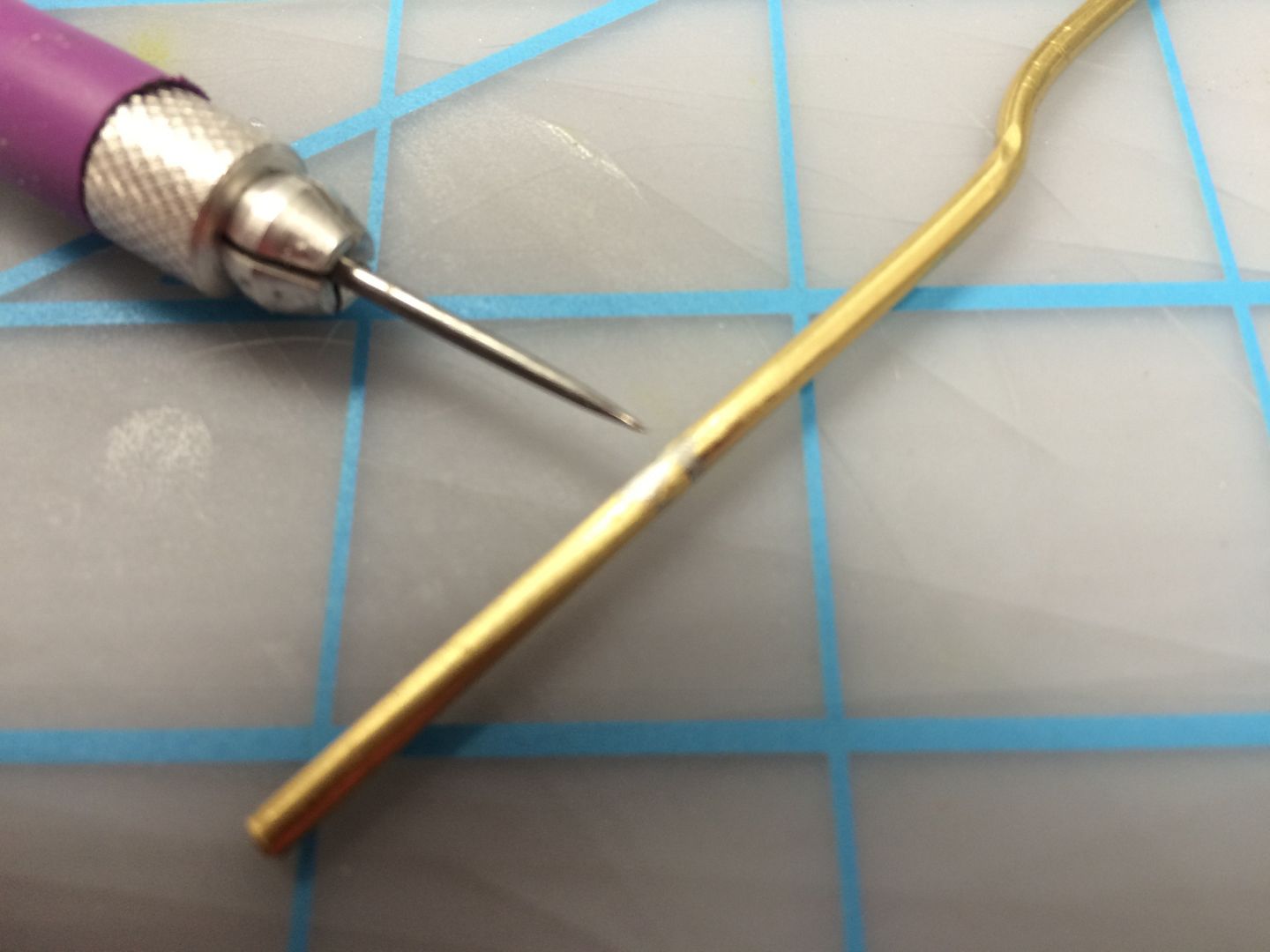

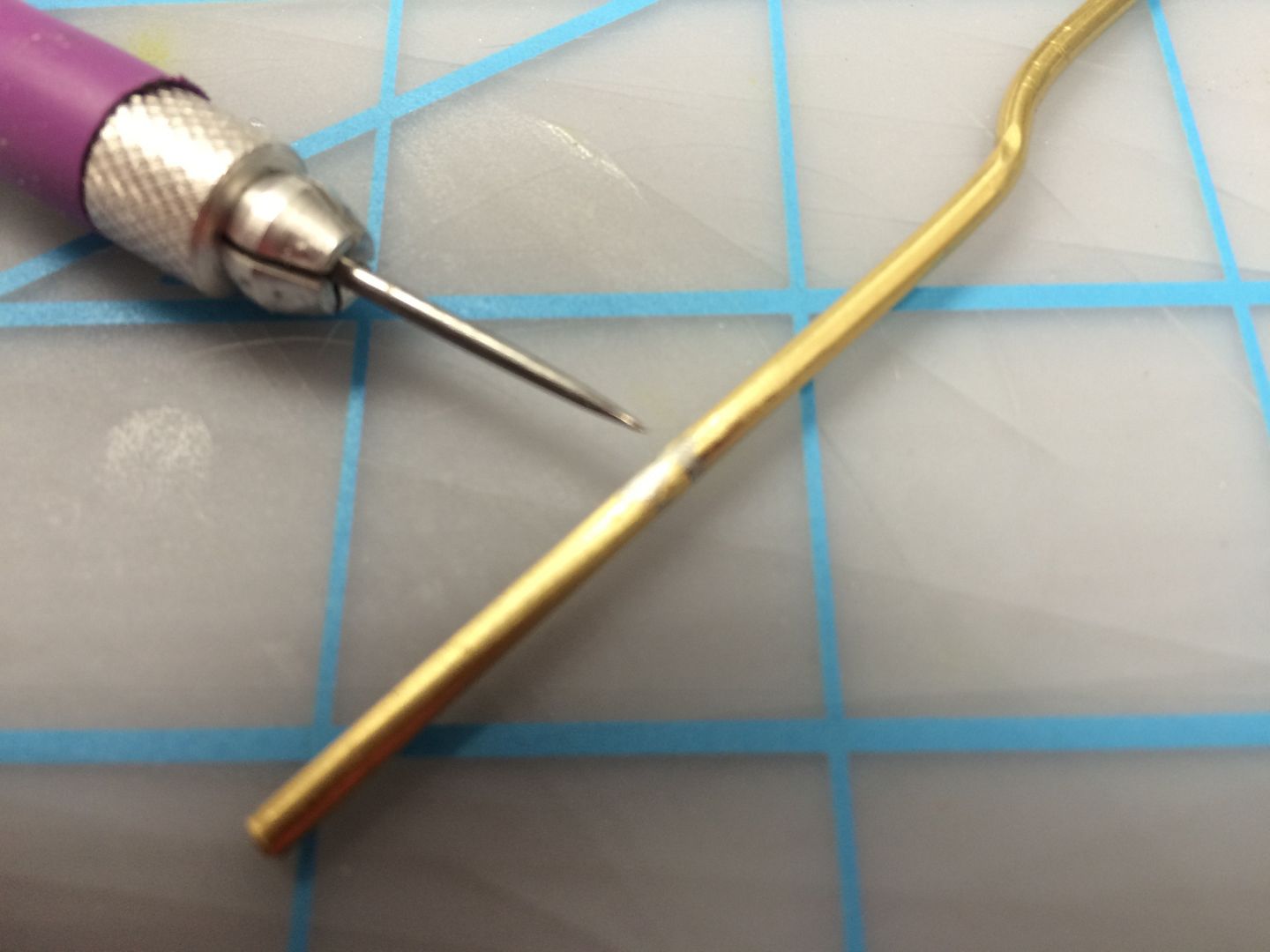

I did manage to get the chrome sprayed in the cargo area. I need to clear it and then apply the wood grain decals. I tried my hand at making the gurney but ran into kinking at the corners when using brass tubing. I did take two scrap pieces of tubing and solder them together for the first time.

Not too bad considering this was my first time. Ian has a neurosurgery checkup in Baton Rouge on Wednesday. A few blocks away is a nice hobby shop that has a bit of everything including brass rod so I will pick some up after the appointment.

After I got finished soldering and learning as I went, I remembered that I have Adam Wilder's DVD on working with photoetch. I popped it in the laptop and fixed some of my errors in technique. Oh well.

Not too bad considering this was my first time. Ian has a neurosurgery checkup in Baton Rouge on Wednesday. A few blocks away is a nice hobby shop that has a bit of everything including brass rod so I will pick some up after the appointment.

After I got finished soldering and learning as I went, I remembered that I have Adam Wilder's DVD on working with photoetch. I popped it in the laptop and fixed some of my errors in technique. Oh well.