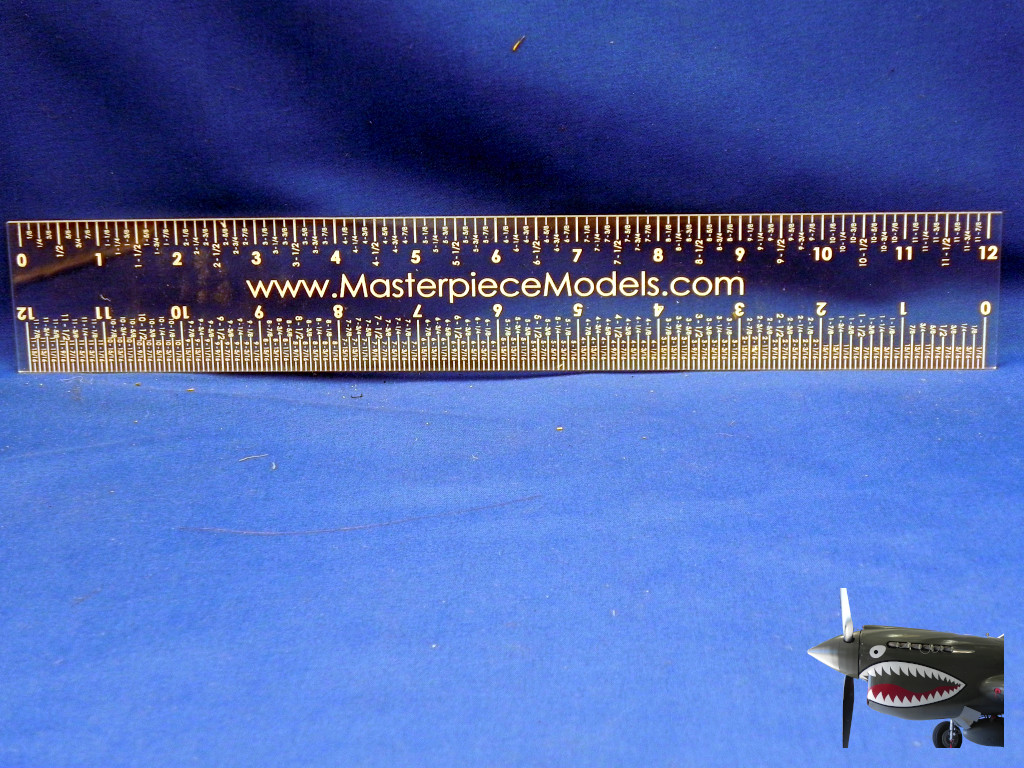

Masterpiece Models has released several laser-engraved acrylic rulers. The reason for these rulers is to measure items accurately so, let's take a closer look:

12-inch ruler made from 0.105-inch acrylic with 1/8th inch increments on one side and 1/16th inch on the other-

My digital micrometer was zeroed out and then set to 1.000 inch. Taking care to align the points to the start of the engraving shows a VERY high degree of accuracy!

I have a habit of trying to improve my tools. This is not a slight on the companies, simply things I do. The first will be to use a black ink wash in the engraved areas. Being acrylic, stress, scratches, and oxidation show up as opacity in the white spectrum. Having them in black ensures visibility. At the moment, there is no rush.

However, I want to use these rulers to set up the stock stops on my cutting tools like, The Chopper II.

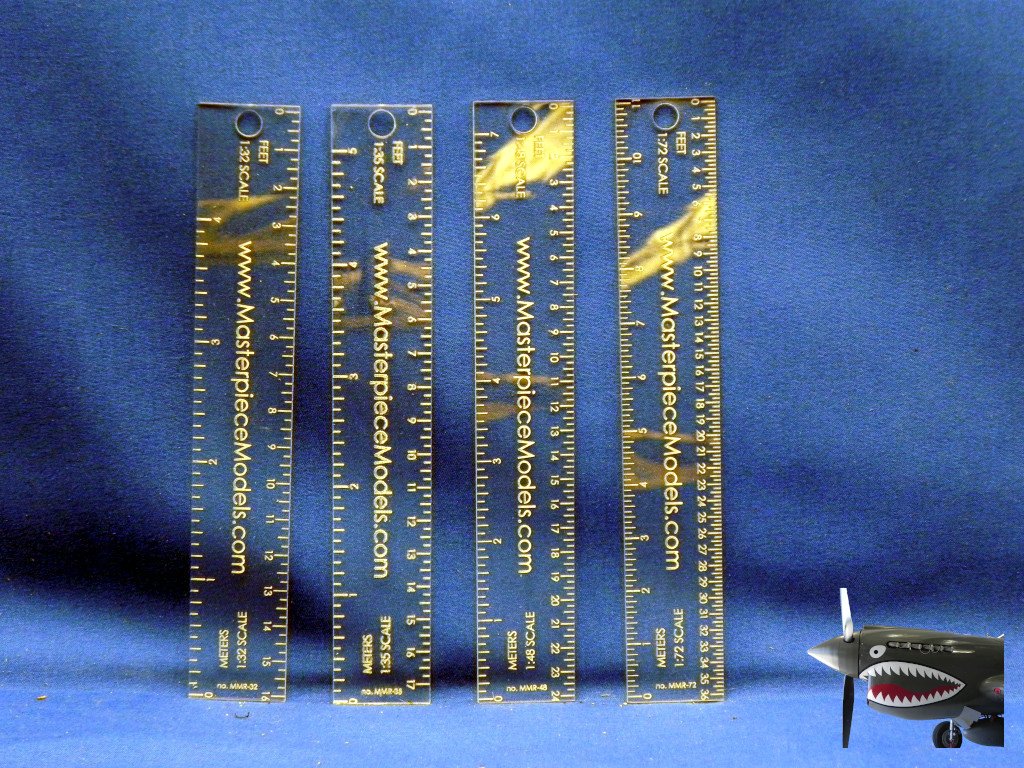

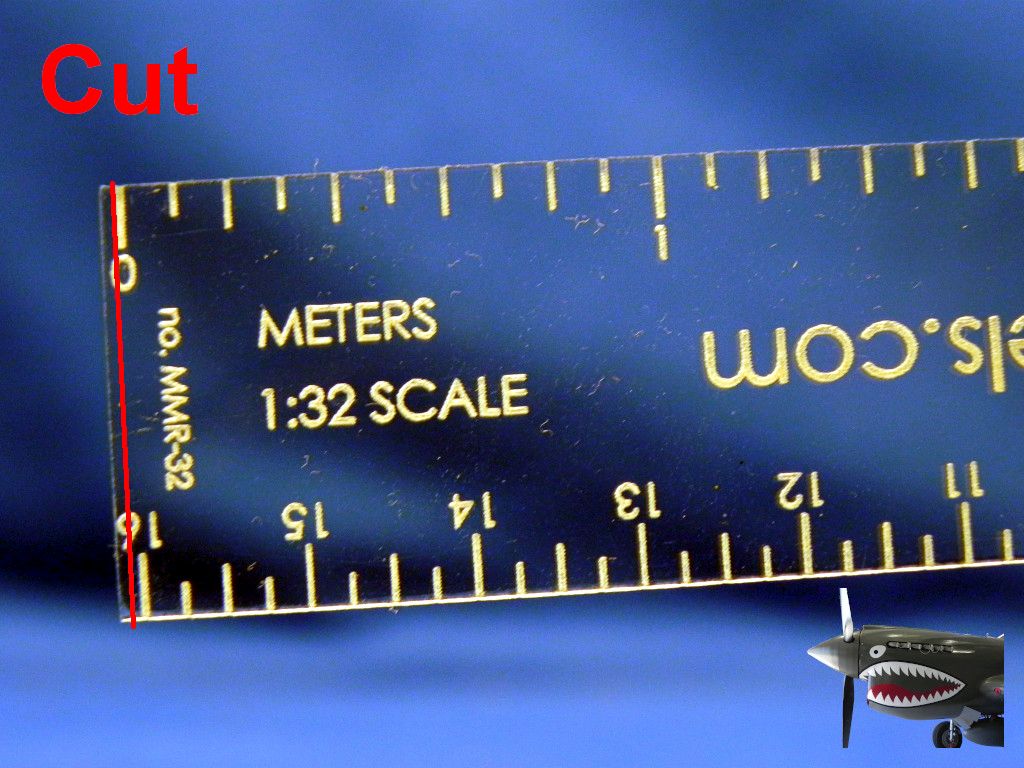

The 6-inch scale rulers are laser engraved on thinner 0.057-inch acrylic. From left to right, they are scaled to 1:32nd, 1:35th ,1:48th, and 1:72nd scale to a high degree of accuracy. Once sire is calibrated in scale feet while the other is in scale meters.

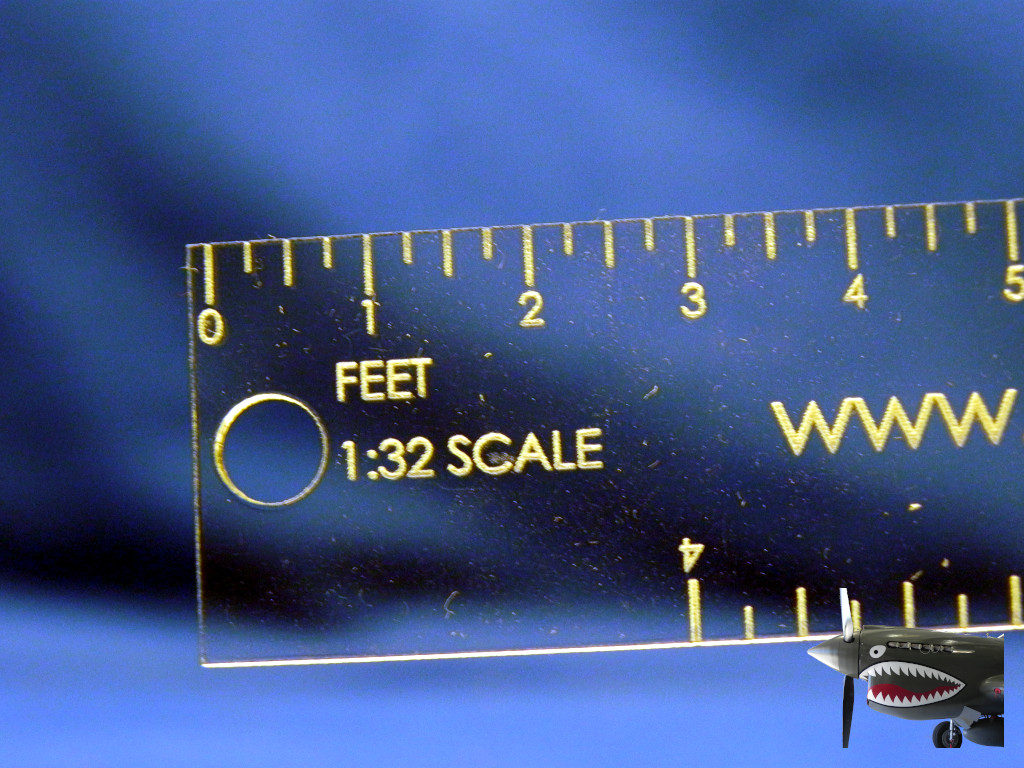

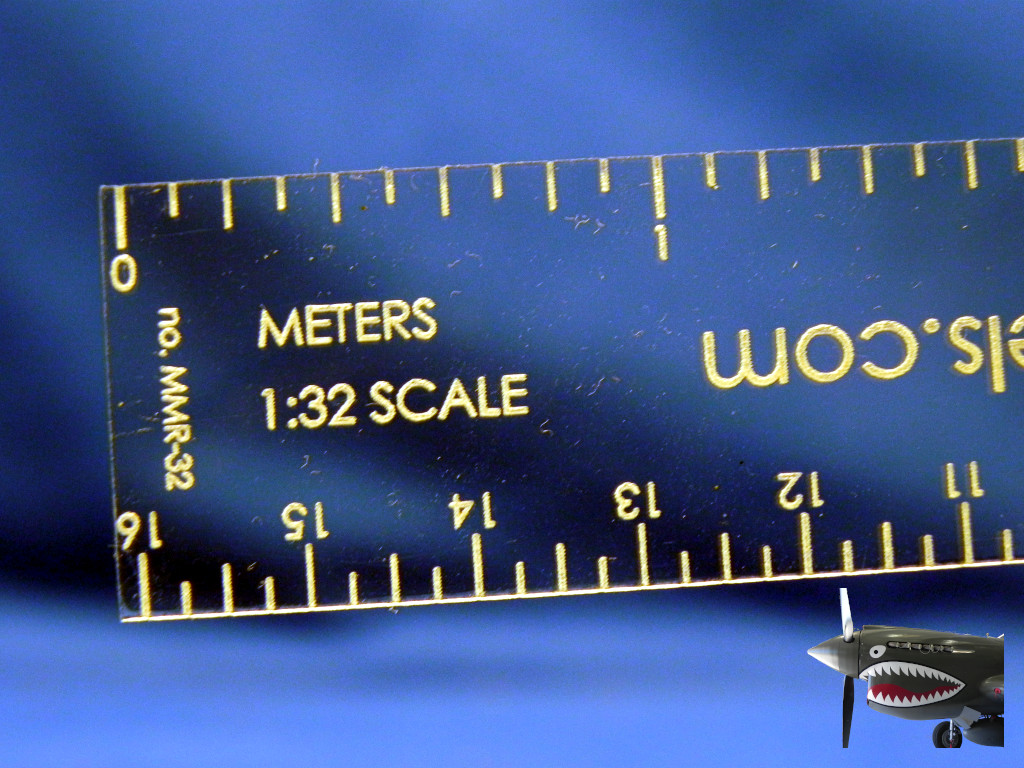

Close-up of MMR-32 (32nd scale) showing that the engraving starts a bit inwards from the corner.

Since I want to use these accurate rulers to place my stops on The Chopper II (and mini table saw), I need to trim off the excess prior to the start of the engravings. So, I will cut the tips off.

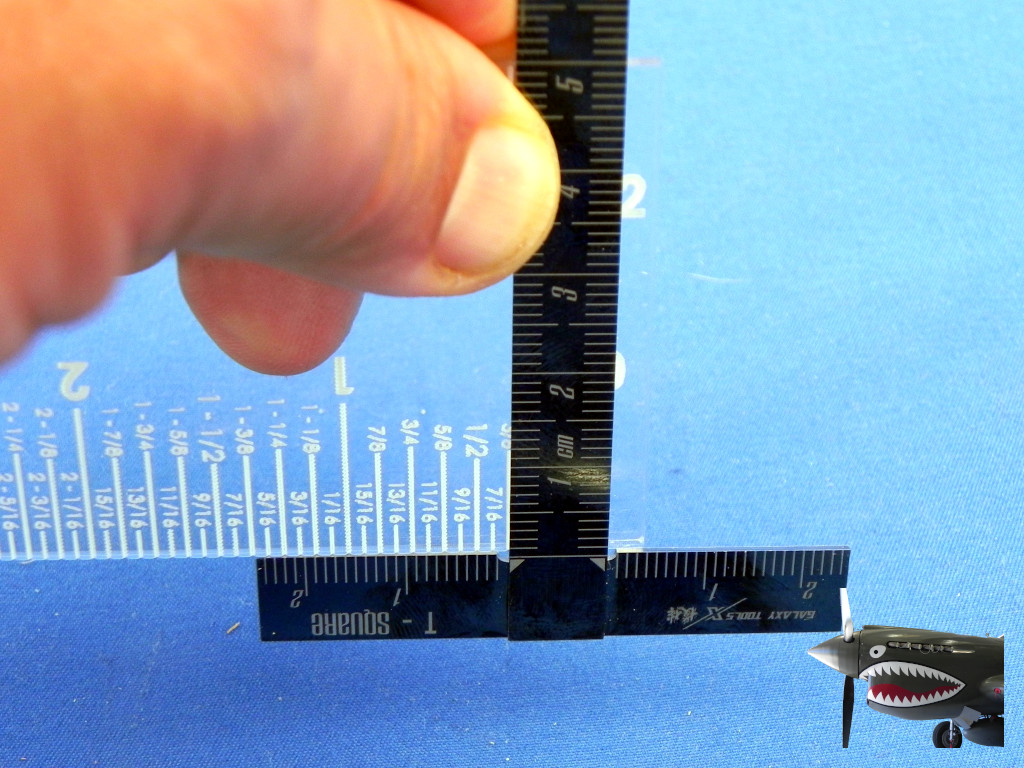

I used a T-Square to ensure I scribed a perpendicular line outside the start of the first engraving.

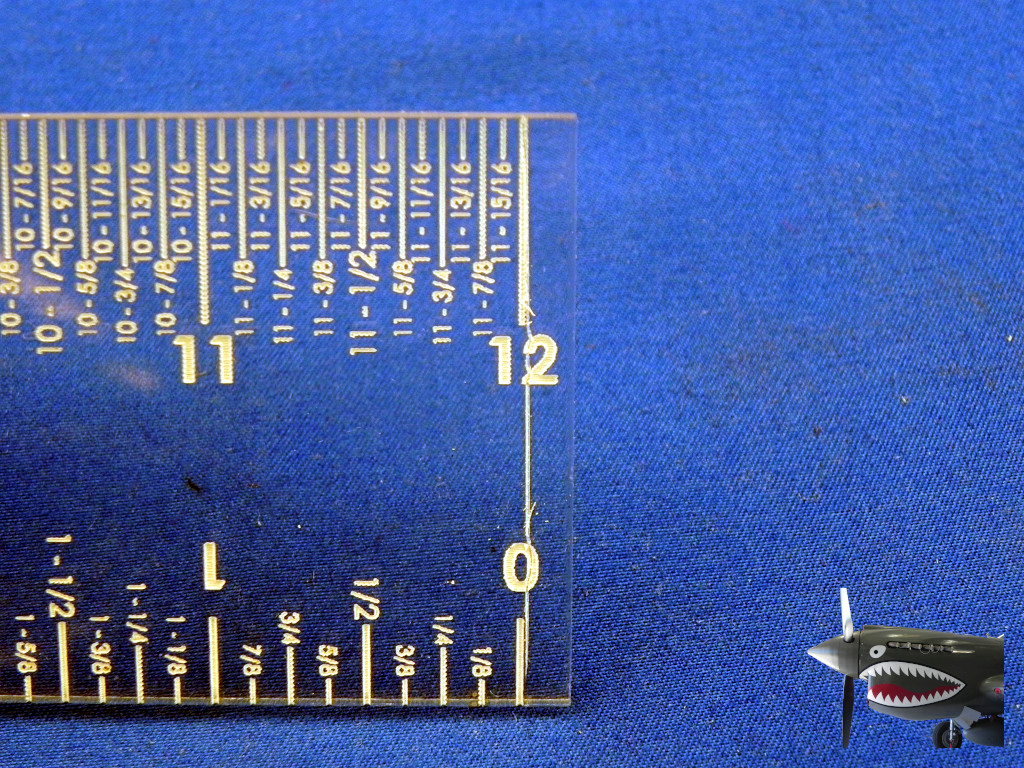

Try not to rush, as I did, since the scriber may slip. Fortunately, outside the area I want to keep.

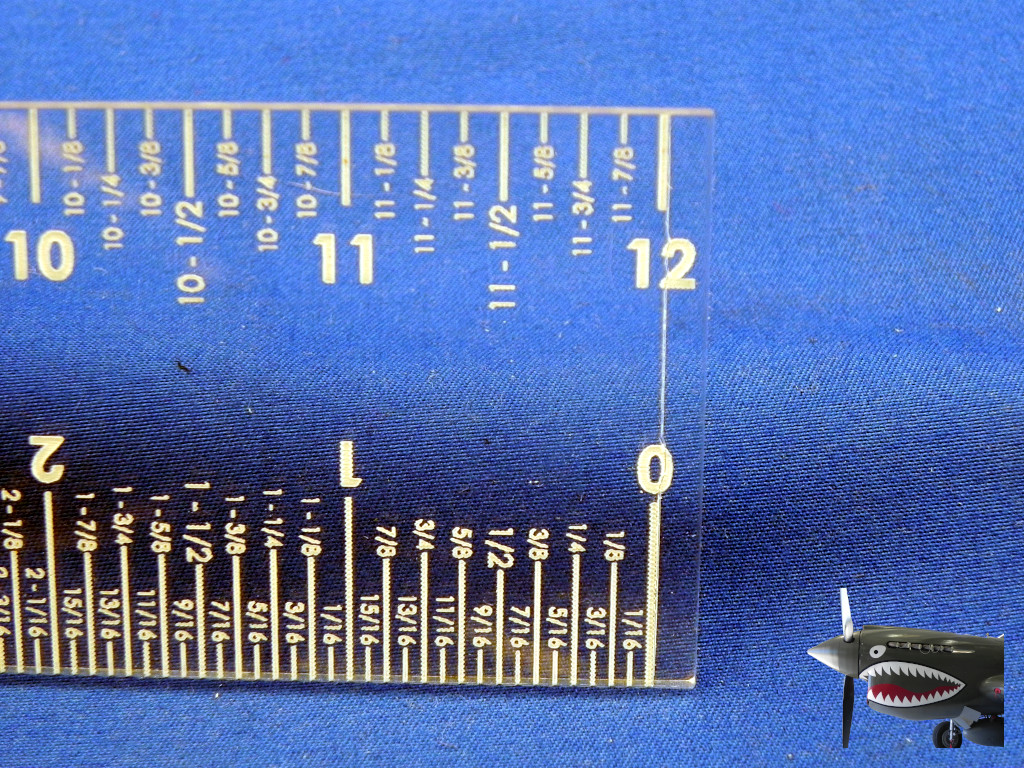

Did much better here...

My thanks to John Geigle of Masterpiece Models for the samples. They can be bought directly from Masterpiece Models.

12-inch ruler made from 0.105-inch acrylic with 1/8th inch increments on one side and 1/16th inch on the other-

My digital micrometer was zeroed out and then set to 1.000 inch. Taking care to align the points to the start of the engraving shows a VERY high degree of accuracy!

I have a habit of trying to improve my tools. This is not a slight on the companies, simply things I do. The first will be to use a black ink wash in the engraved areas. Being acrylic, stress, scratches, and oxidation show up as opacity in the white spectrum. Having them in black ensures visibility. At the moment, there is no rush.

However, I want to use these rulers to set up the stock stops on my cutting tools like, The Chopper II.

The 6-inch scale rulers are laser engraved on thinner 0.057-inch acrylic. From left to right, they are scaled to 1:32nd, 1:35th ,1:48th, and 1:72nd scale to a high degree of accuracy. Once sire is calibrated in scale feet while the other is in scale meters.

Close-up of MMR-32 (32nd scale) showing that the engraving starts a bit inwards from the corner.

Since I want to use these accurate rulers to place my stops on The Chopper II (and mini table saw), I need to trim off the excess prior to the start of the engravings. So, I will cut the tips off.

I used a T-Square to ensure I scribed a perpendicular line outside the start of the first engraving.

Try not to rush, as I did, since the scriber may slip. Fortunately, outside the area I want to keep.

Did much better here...

My thanks to John Geigle of Masterpiece Models for the samples. They can be bought directly from Masterpiece Models.