Sorry for not getting back to this earlier...been another crazy week on the homestead.

I received a couple of offline questions about what tools (if any) I have for working with PE and also what Am I having problems with.

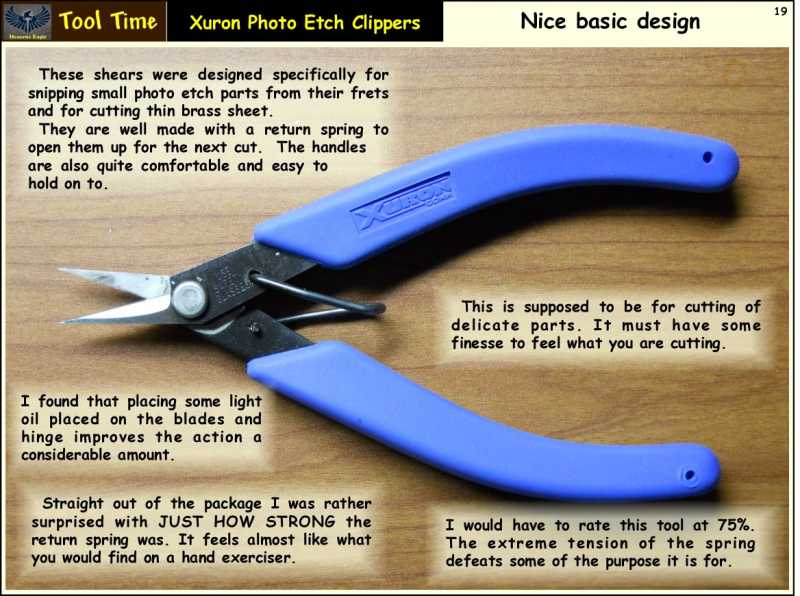

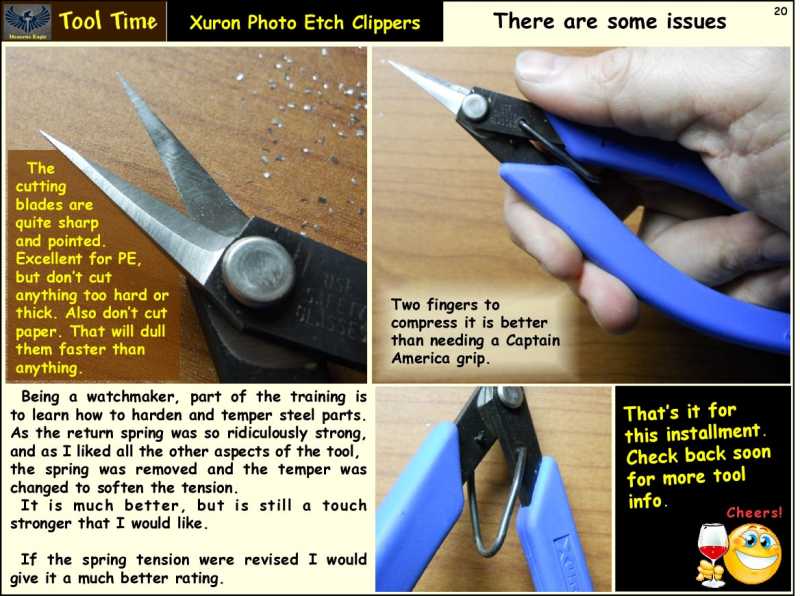

So first the tools...

So as you can see I thinking I'm ok on proper tools but you will notice no soldering setup, so that will have to be addressed if I decide to continue messing with PE in the long term.

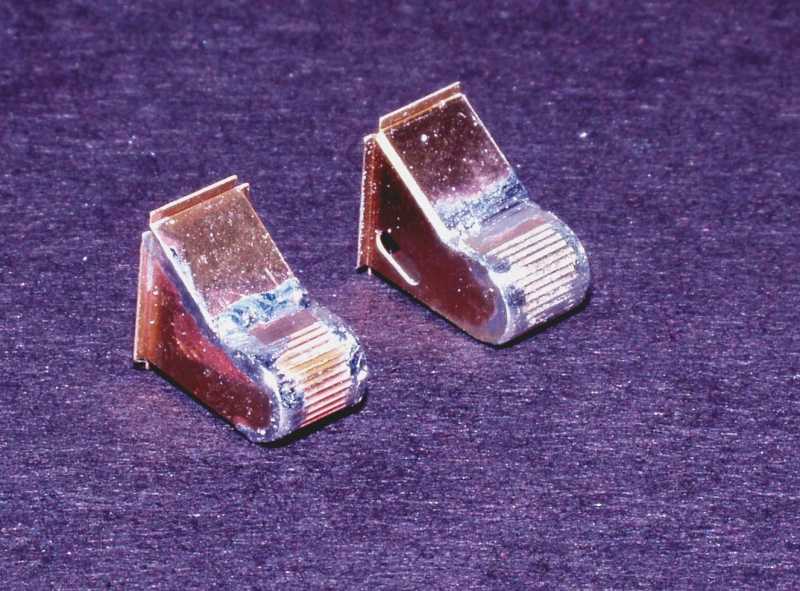

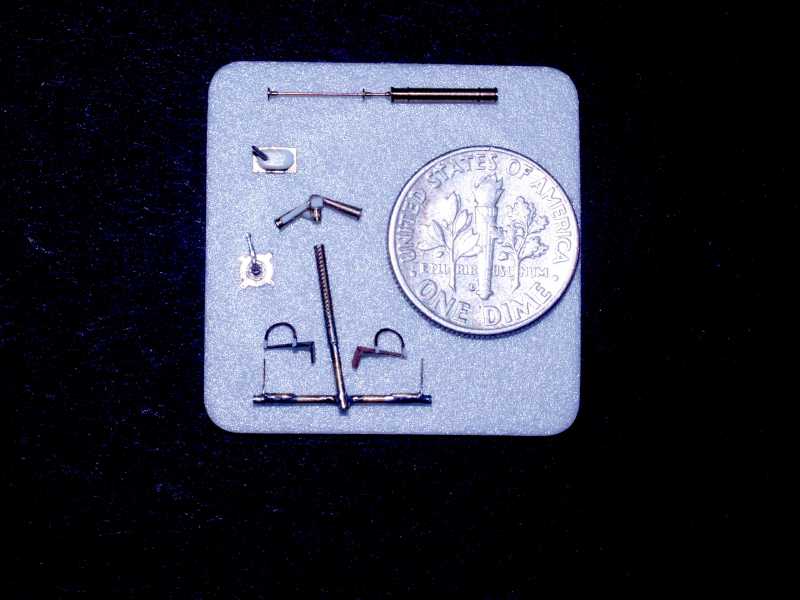

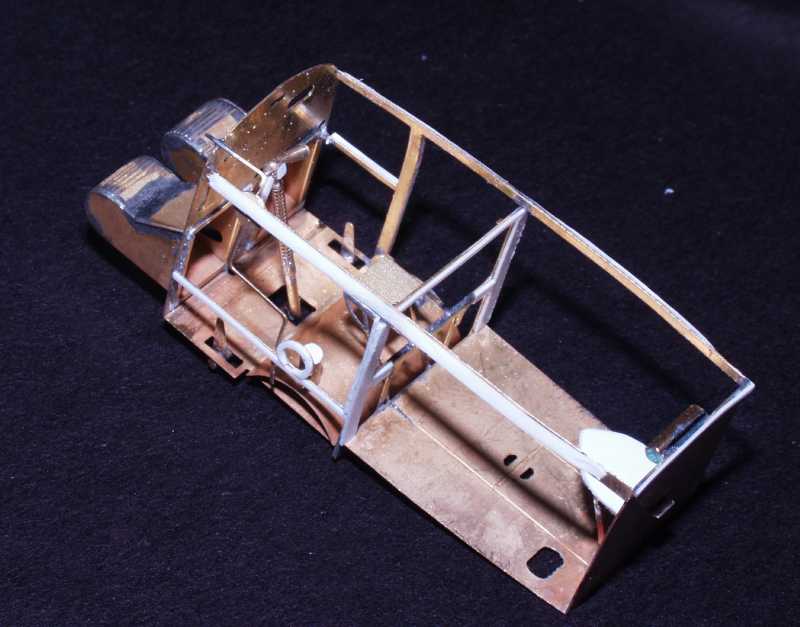

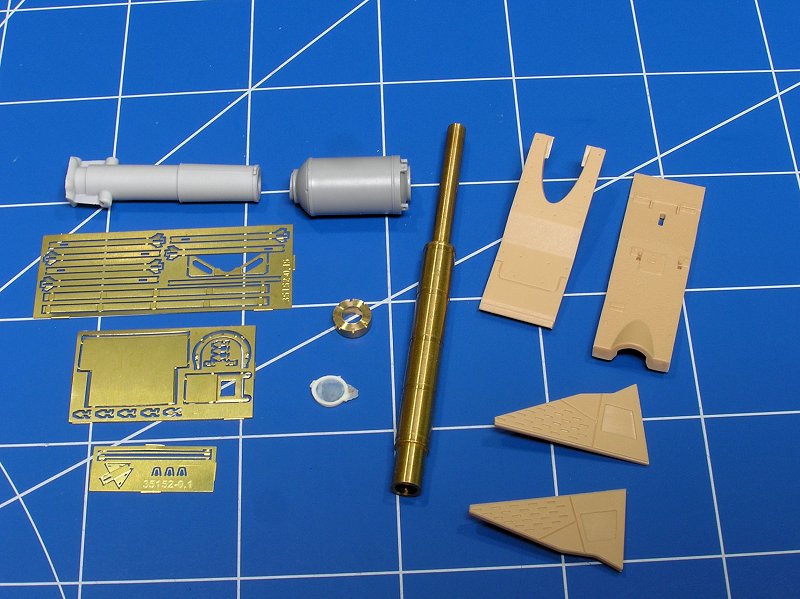

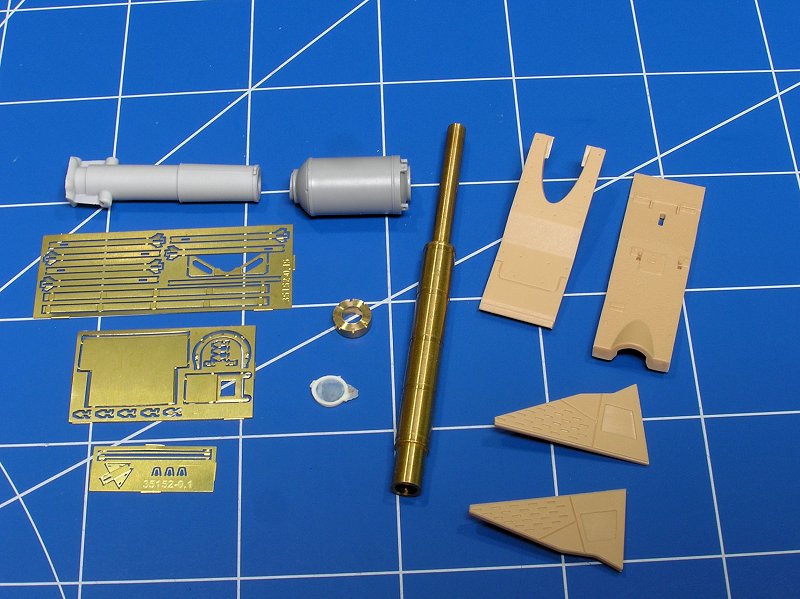

As for "what I'm having problems with" is a little more difficult to directly answer. The photos below show what I was working with during this most recent...fun fest...NOT!

I think the issues fall into three areas.

1. Mindset. For whatever reason I totally stress myself out about working with PE even before I start. I feel like I have only one shot to get it "right" and if it doesn't happen then the entire PE project is botched. Unlike styrene when I can just chuck the botched attempt and start over, for PE I have to buy a new set.

2. Ridiculously small parts and crazy as shapes. I mean really who the hell is thinking up some of the stuff. As I get older my eyesight is getting worst so it harder to see what it is my doing.

3. Lack of Dexterity. My stubby little fingers just don't seem to have the feaness needed to work with the ridiculously small parts

So the above three items happen more or less at the same time resulting in the fun of the hobby getting totally sucked out of the room and destroying any of my motivation to continue. Then I ask myself "what am I even putting up with this for"...Dude Just build the way you want and enjoy it for what it is.

See working like this doesn't help either Armorama Merkava Mk3.

Sorry for the RANT :facepalm :smack

I received a couple of offline questions about what tools (if any) I have for working with PE and also what Am I having problems with.

So first the tools...

So as you can see I thinking I'm ok on proper tools but you will notice no soldering setup, so that will have to be addressed if I decide to continue messing with PE in the long term.

As for "what I'm having problems with" is a little more difficult to directly answer. The photos below show what I was working with during this most recent...fun fest...NOT!

I think the issues fall into three areas.

1. Mindset. For whatever reason I totally stress myself out about working with PE even before I start. I feel like I have only one shot to get it "right" and if it doesn't happen then the entire PE project is botched. Unlike styrene when I can just chuck the botched attempt and start over, for PE I have to buy a new set.

2. Ridiculously small parts and crazy as shapes. I mean really who the hell is thinking up some of the stuff. As I get older my eyesight is getting worst so it harder to see what it is my doing.

3. Lack of Dexterity. My stubby little fingers just don't seem to have the feaness needed to work with the ridiculously small parts

So the above three items happen more or less at the same time resulting in the fun of the hobby getting totally sucked out of the room and destroying any of my motivation to continue. Then I ask myself "what am I even putting up with this for"...Dude Just build the way you want and enjoy it for what it is.

See working like this doesn't help either Armorama Merkava Mk3.

Sorry for the RANT :facepalm :smack