phantom II

Master at Arms

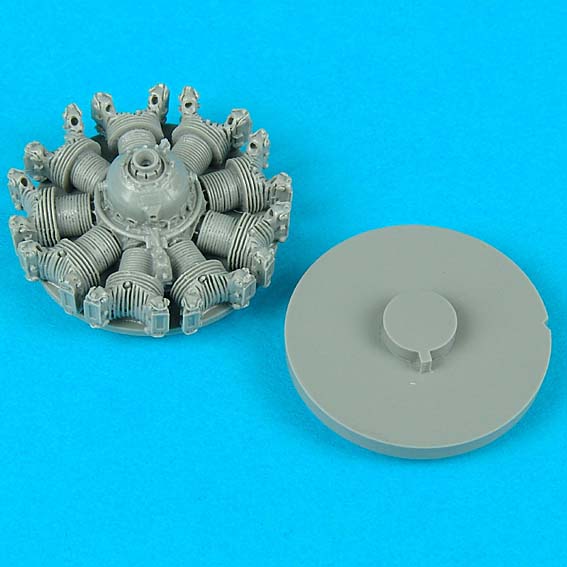

I usually drill the gear reduction or crankcase . Easier to work with in 1/72 , but whatever works for you.

Can't see the holes either after you install the ignition harness .

Good to see progress Bob.

Cheers, Christian B)

Can't see the holes either after you install the ignition harness .

Good to see progress Bob.

Cheers, Christian B)