The Tools:

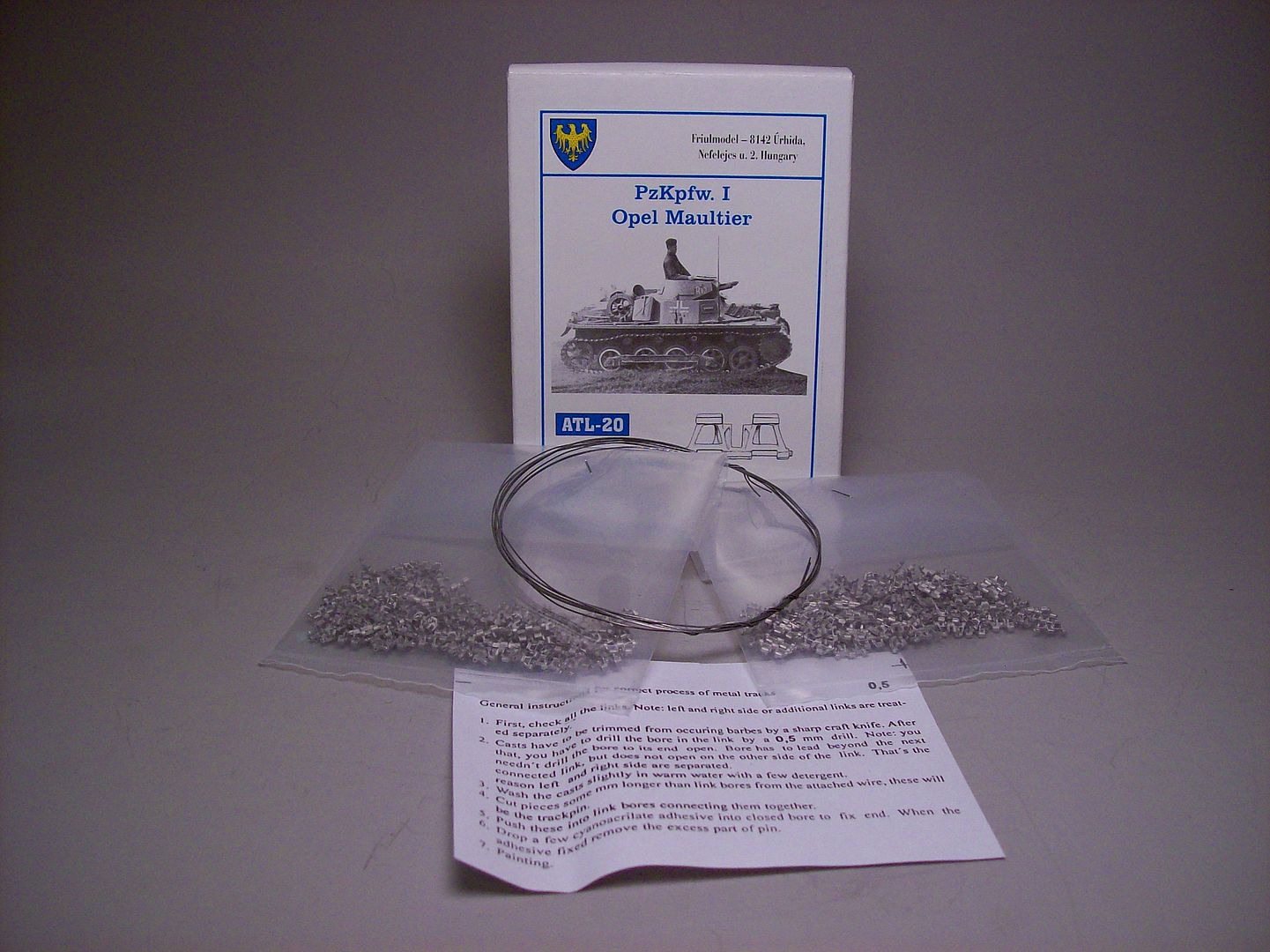

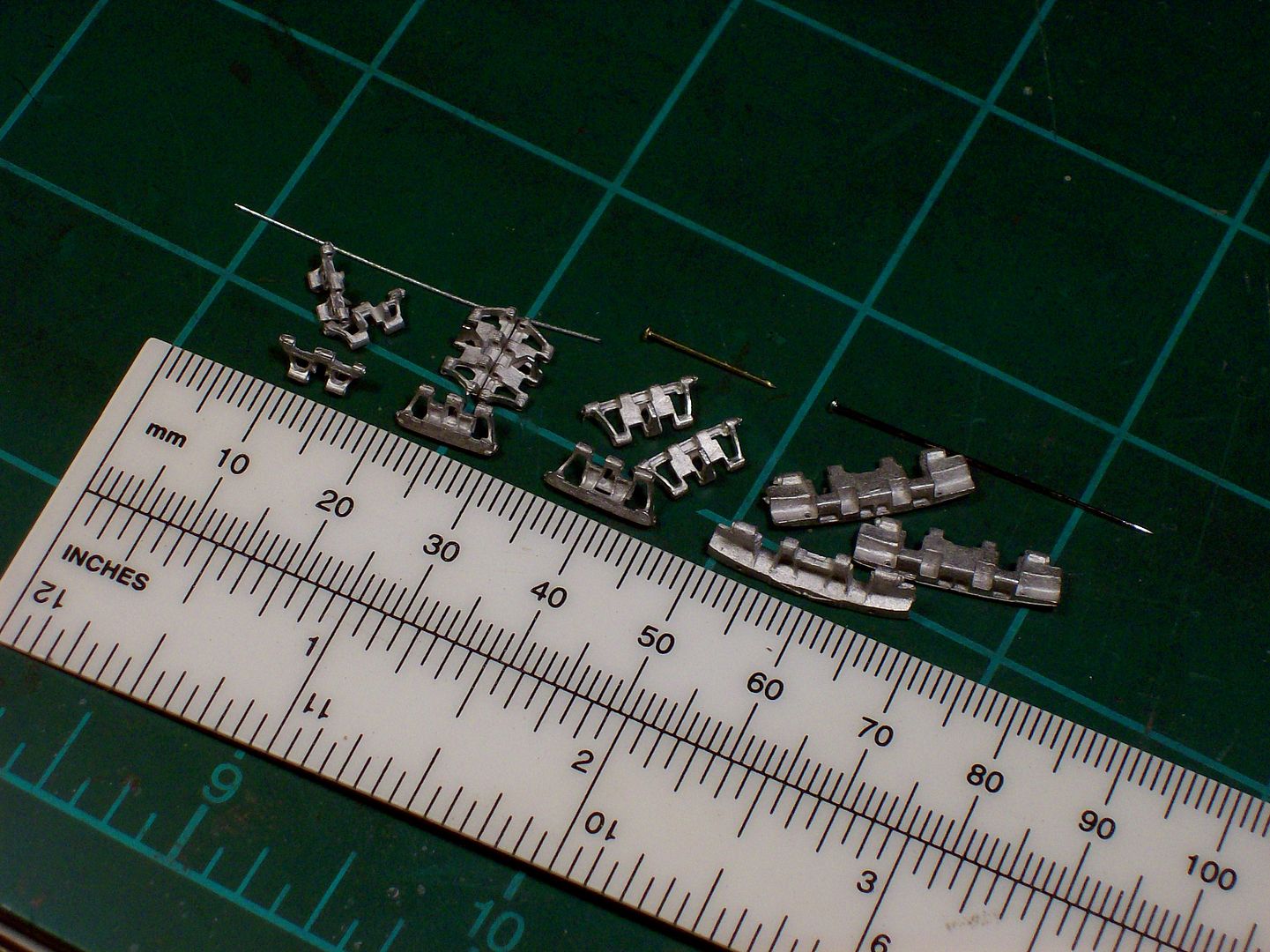

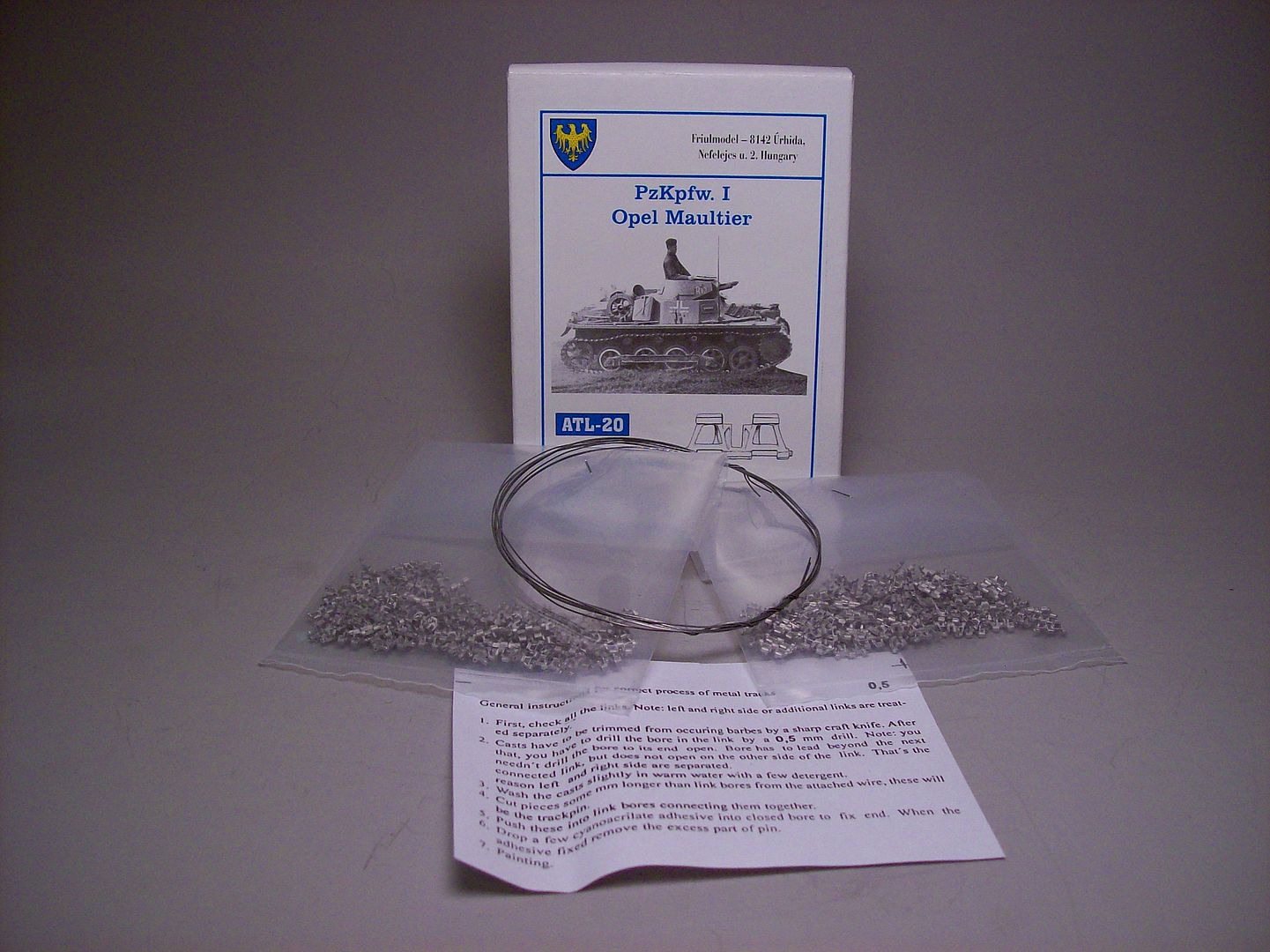

What's in the box:

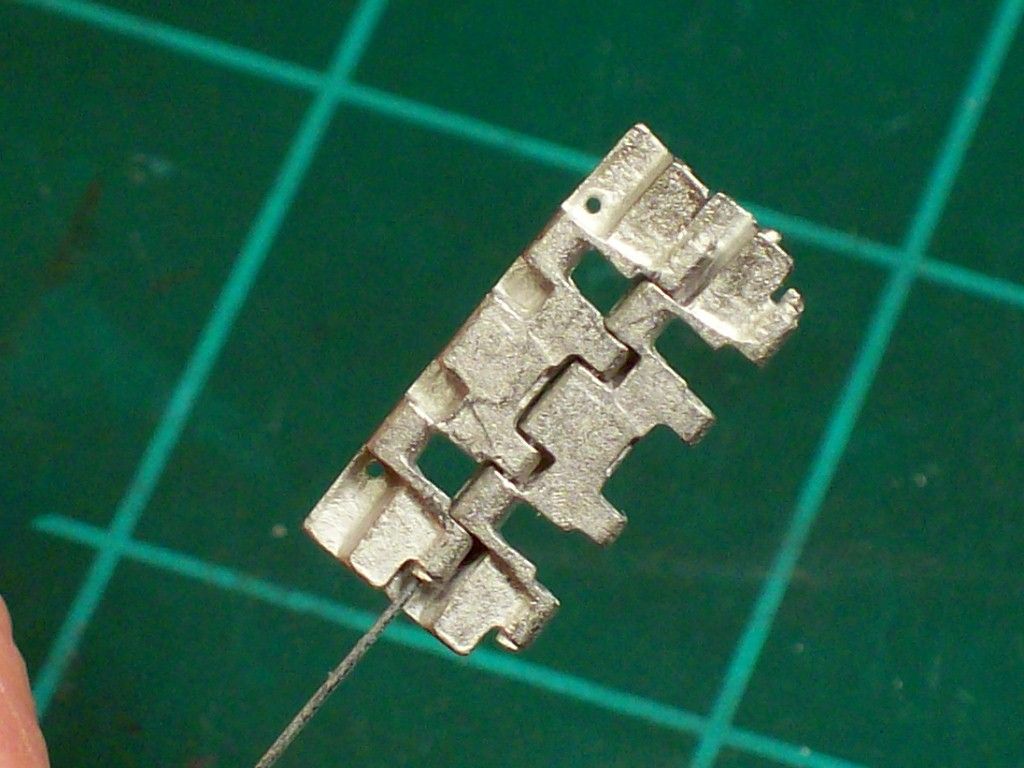

There are two packs of links because, BUT NOT ALWAYS, there are left and right sides so DON'T go and dump both bags into one big pile.

OK Here We Go:

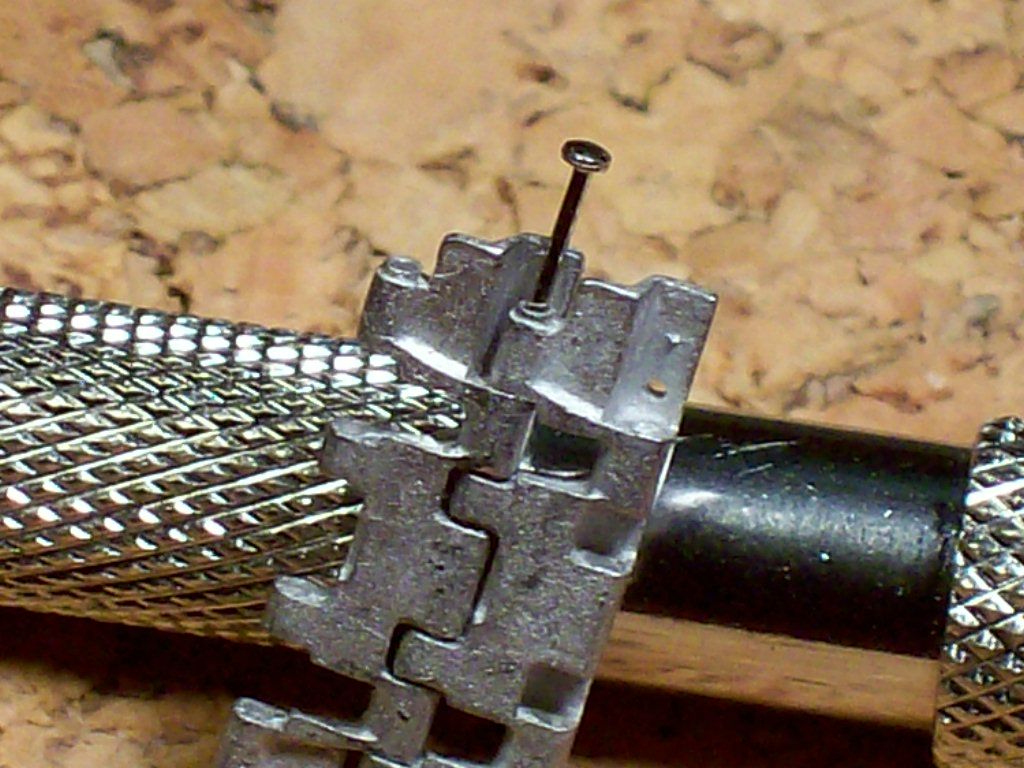

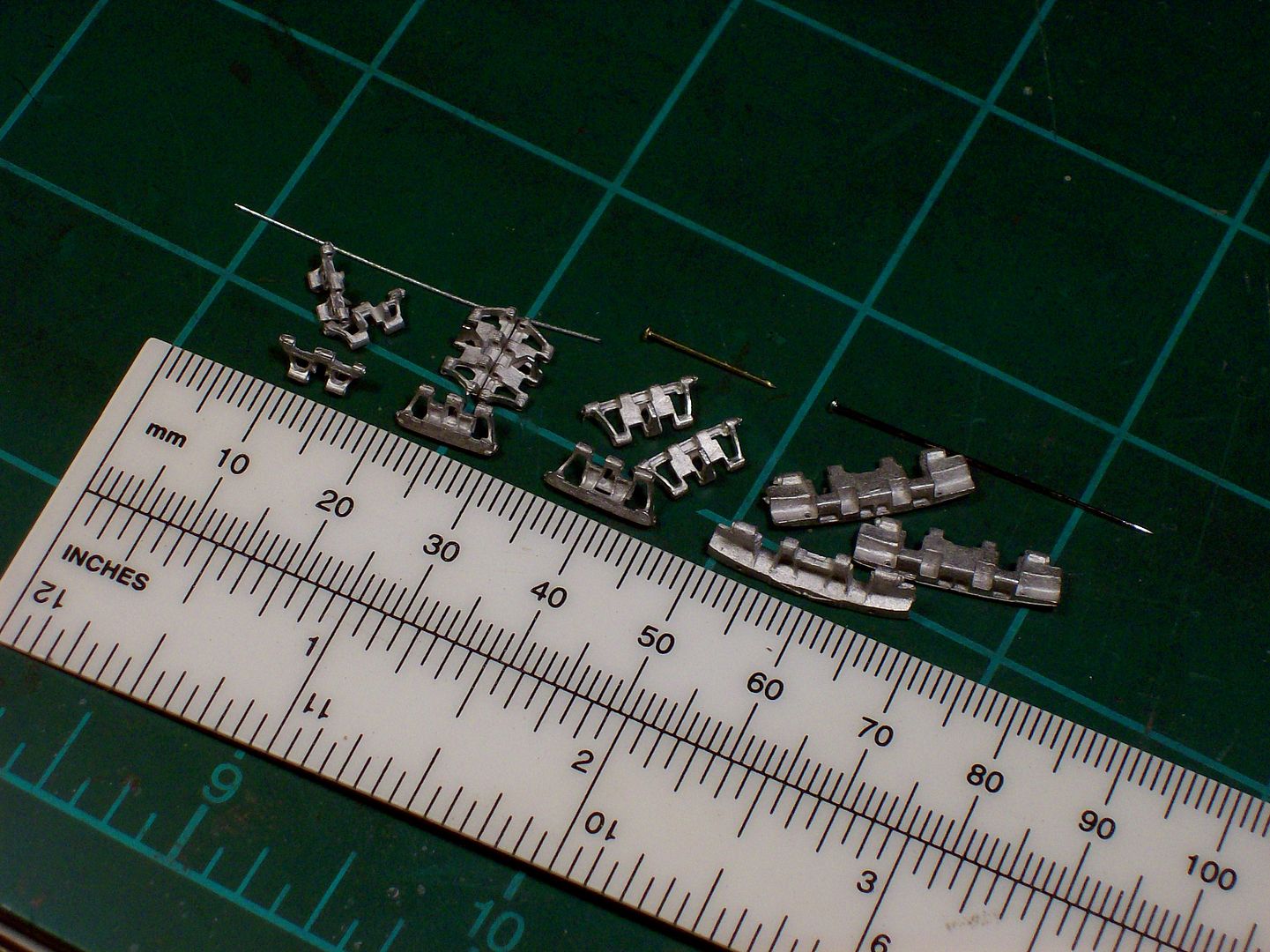

Most everyone uses the supplied wire or brass rod to put the links together but I use dress or sequin pins on the larger tracks and the wire for the smaller tracks.

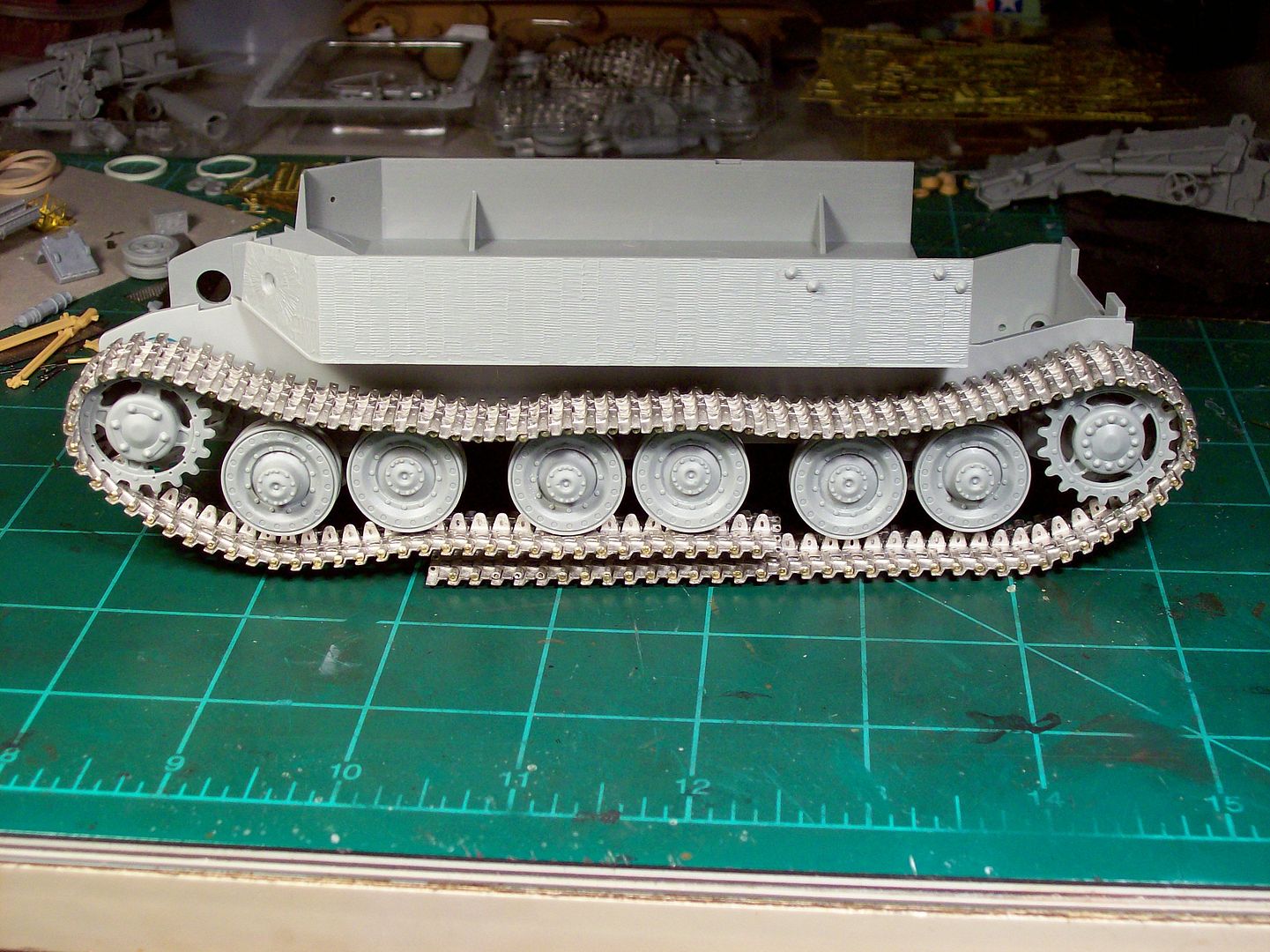

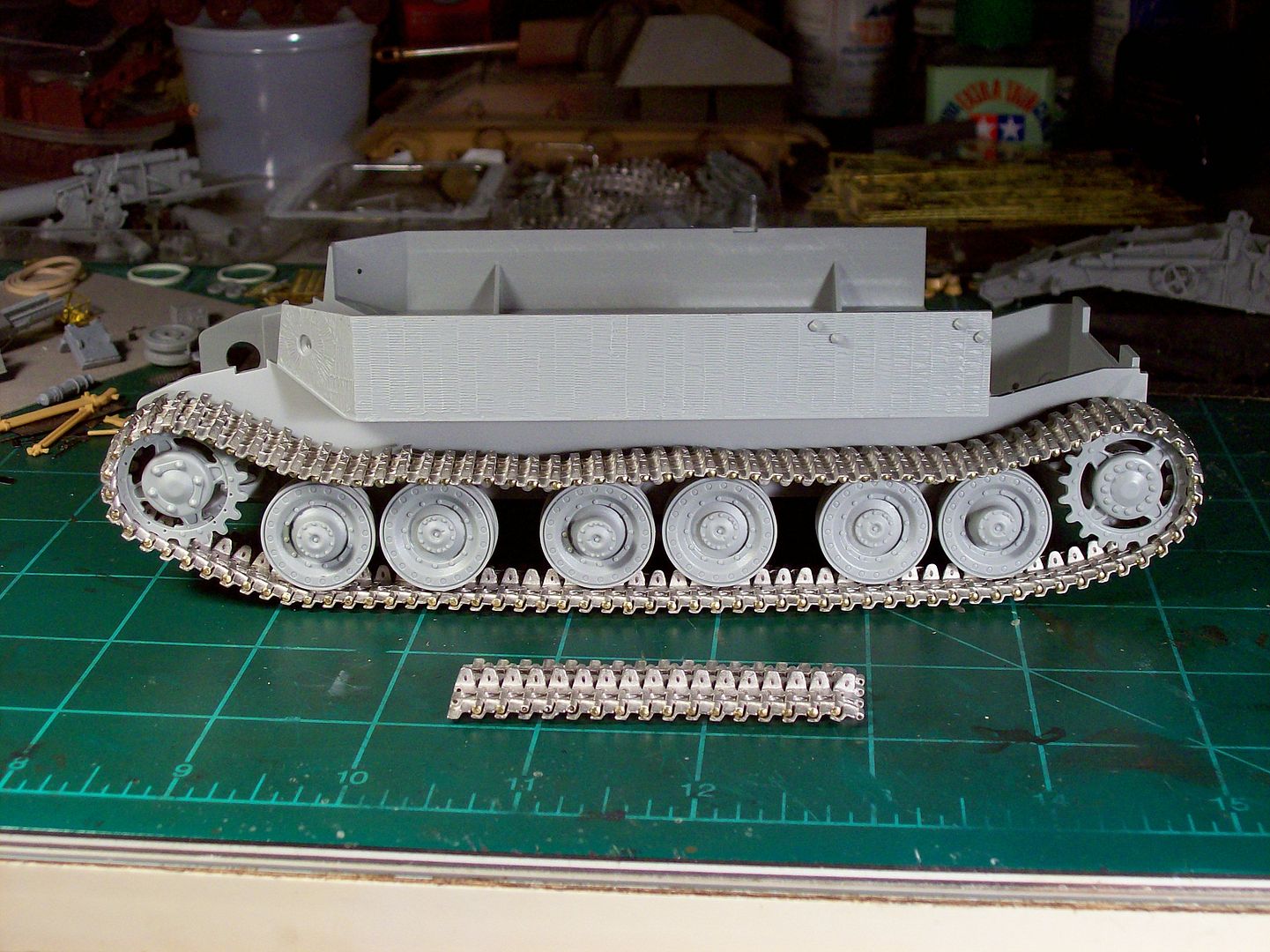

Left to right: Pz 1 and Pz 2 i'll use the wire. Pz 3&4 and larger like the Elefants shown here i'll use the pins.

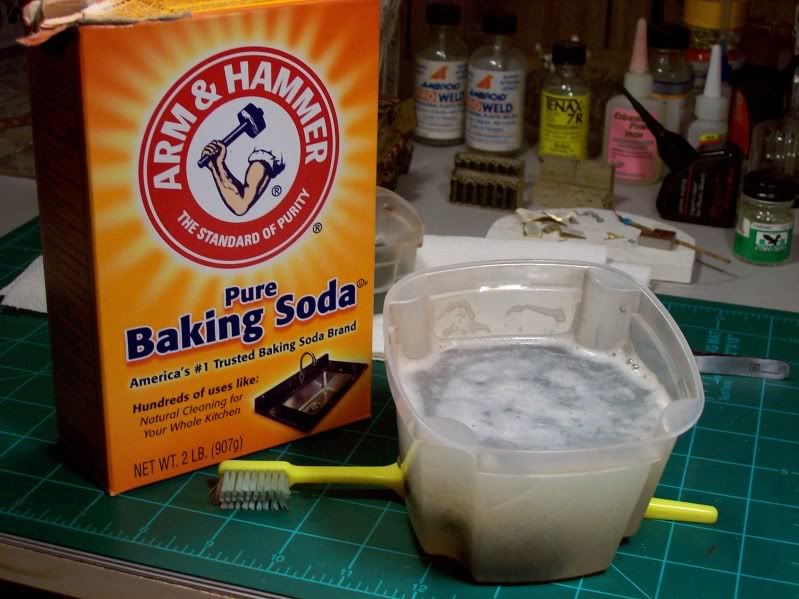

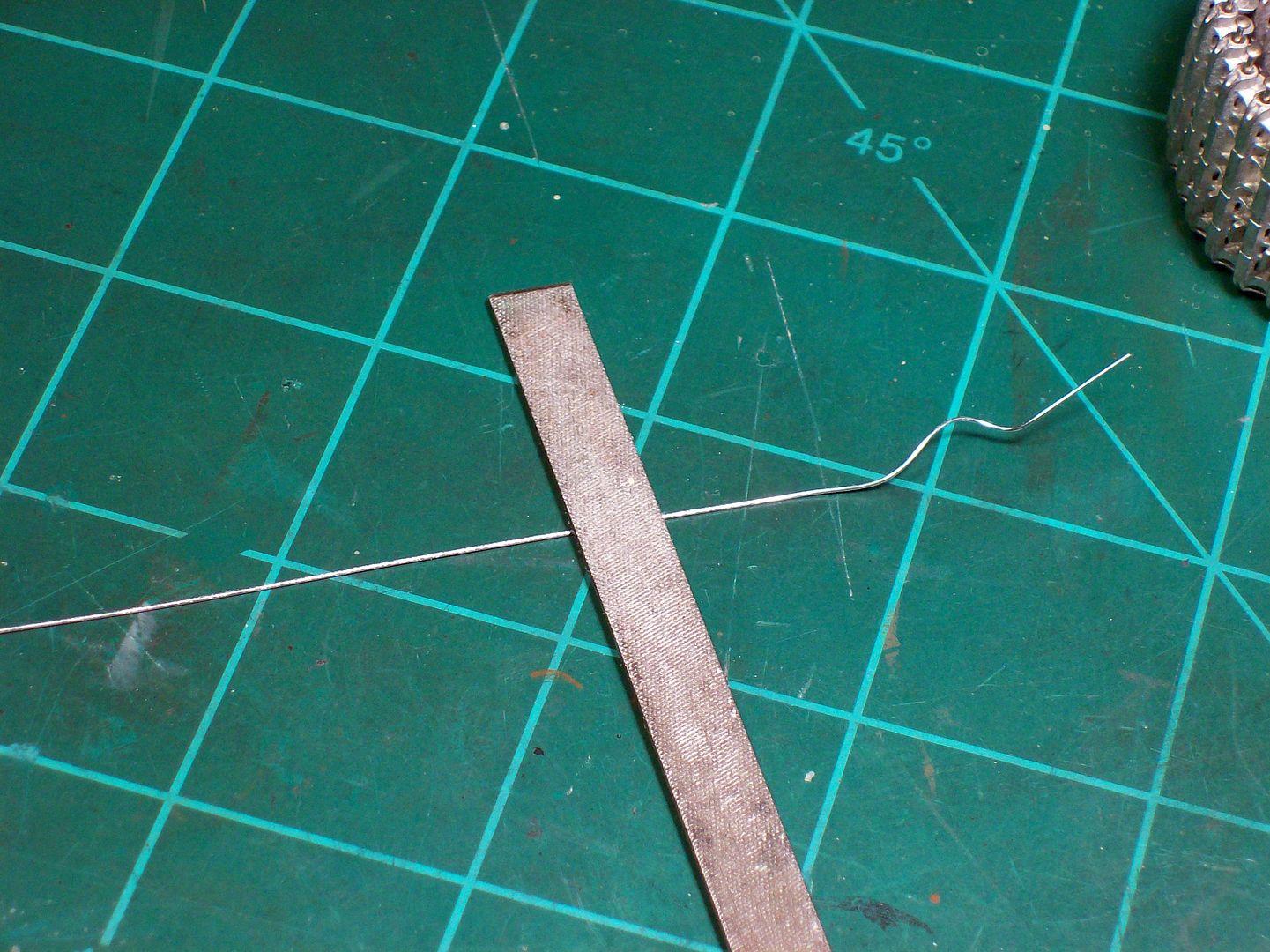

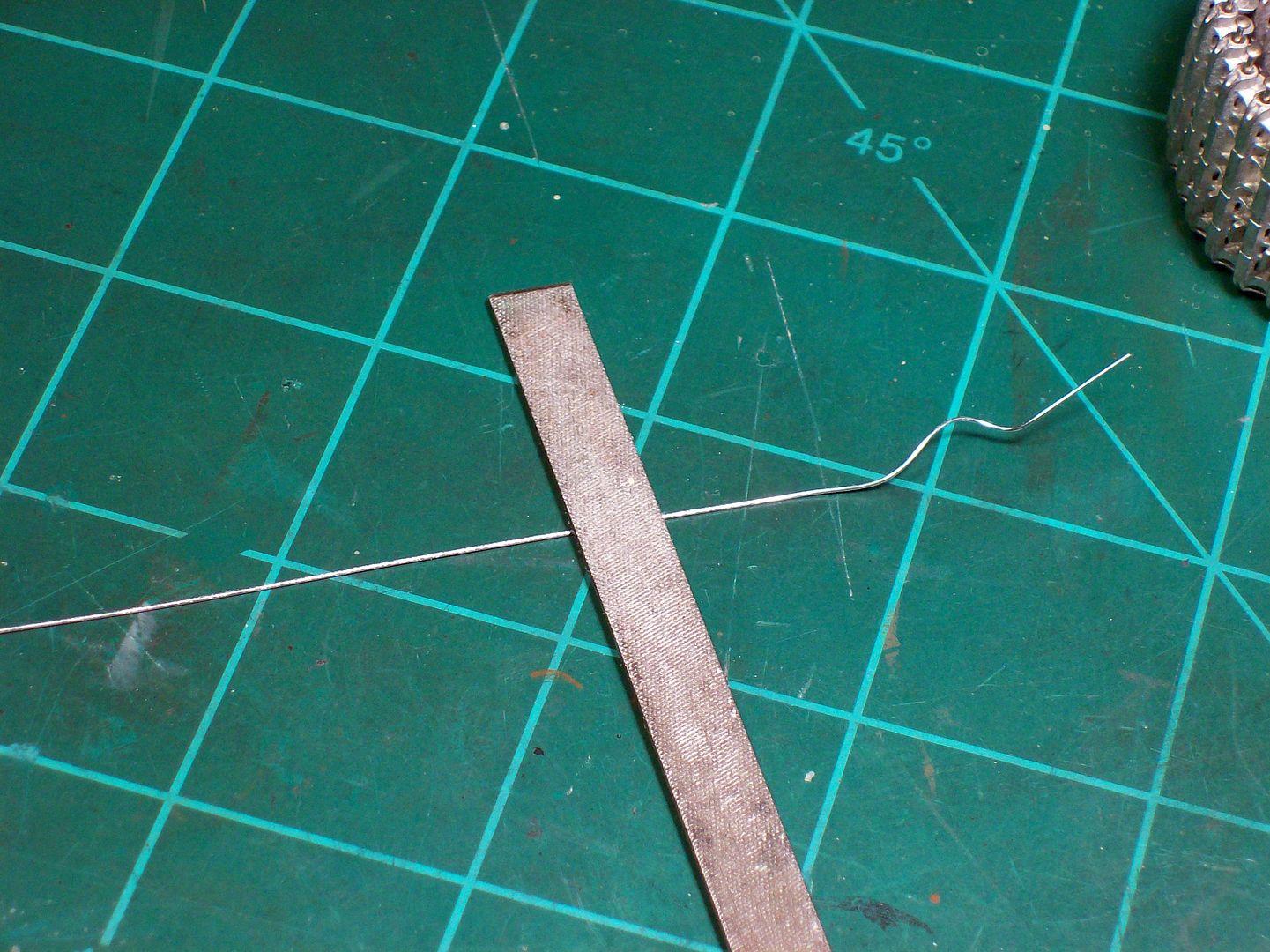

I usually get a lap tray,open one of the link packs and put the links in a container. Cut the wire into manageable lengths and roll the kinks out like so with an old ignition points file.

or cut the dress pins to length. Gather the tools i'll need along with my opt-visor and then flop down in my recliner in front of the TV.

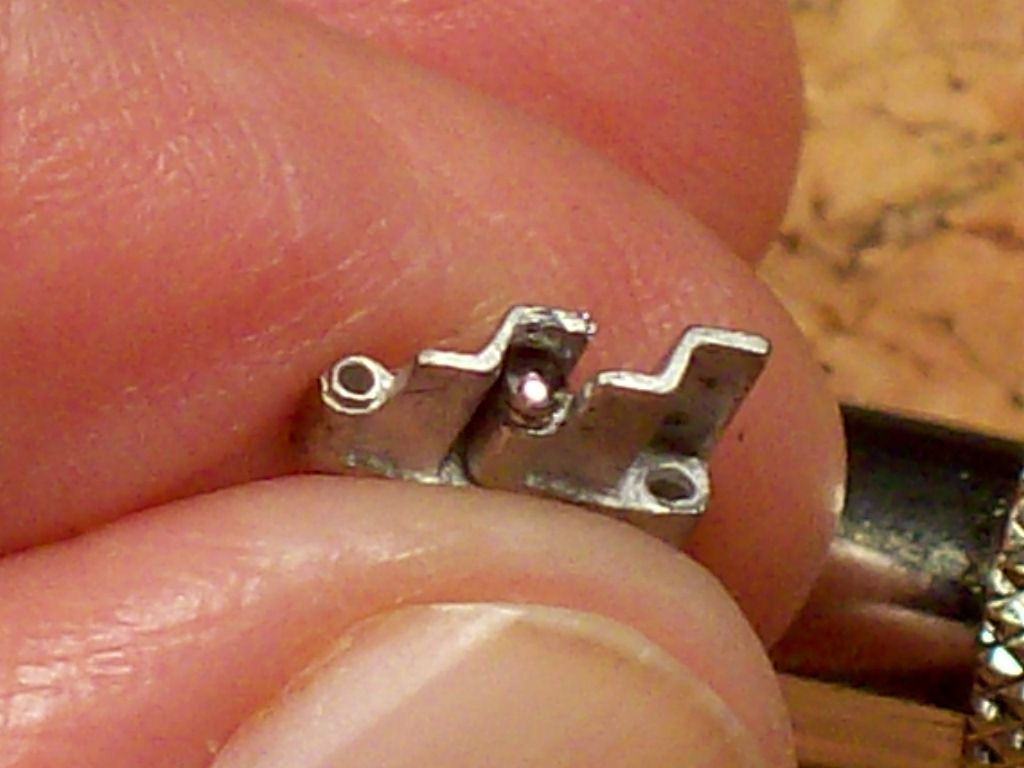

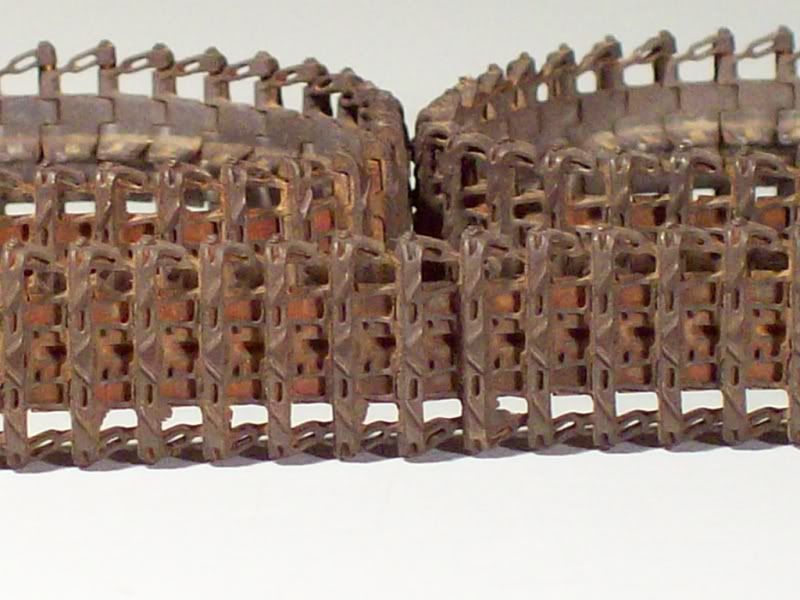

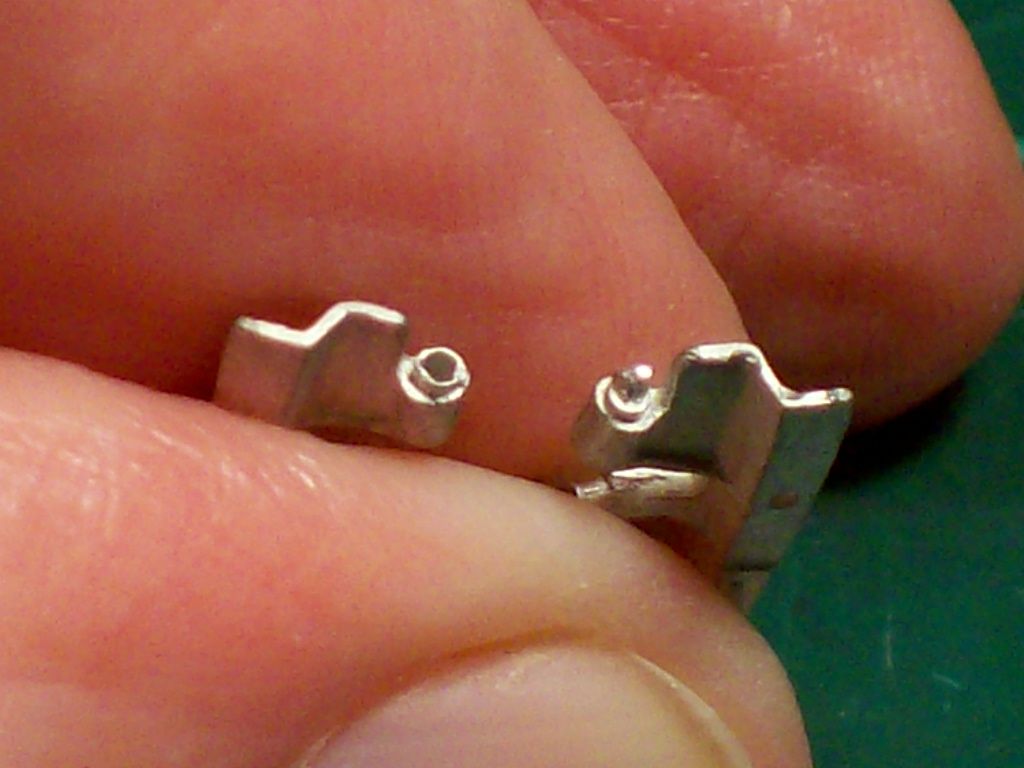

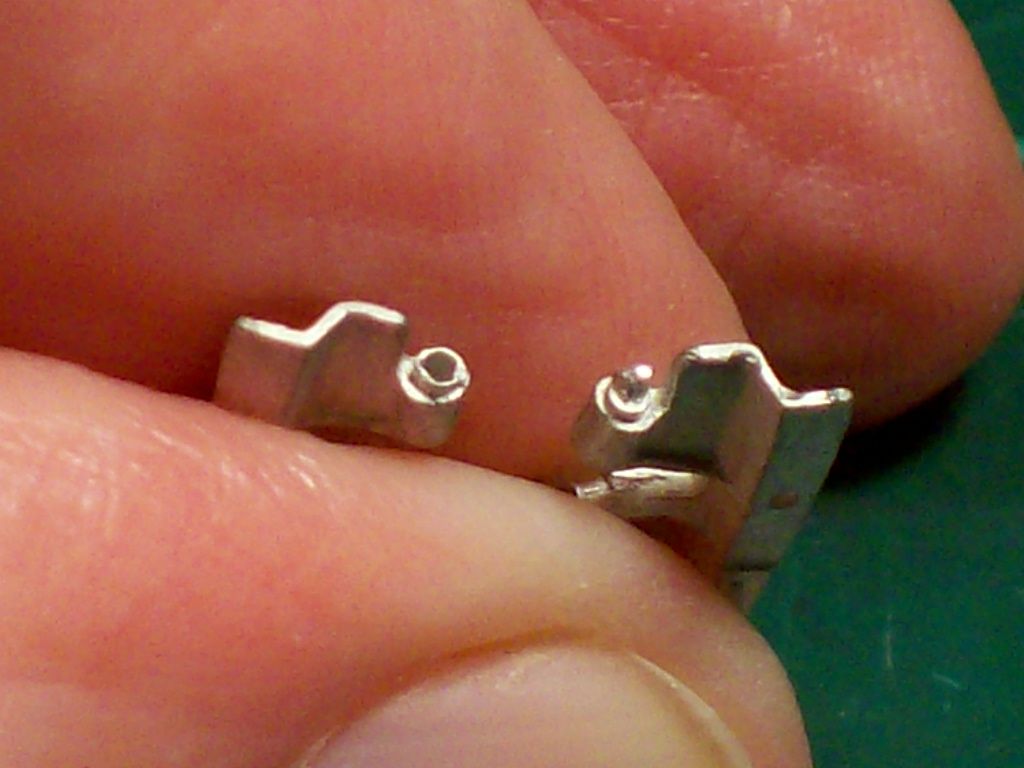

If you look at the links you'll notice one end has a hole for the wire and the other end has link pin detail cast into it. BTW that pin head detail is placed to the outside when mounting the tracks. Now you see why you need to keep the links separate and not in one pile.

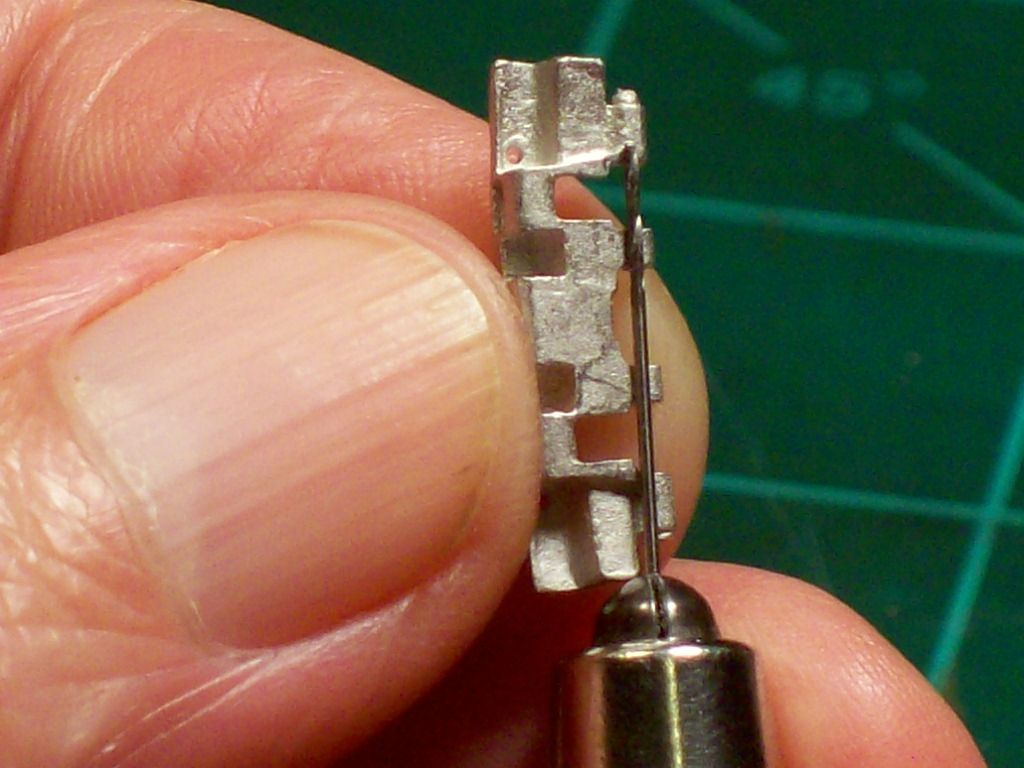

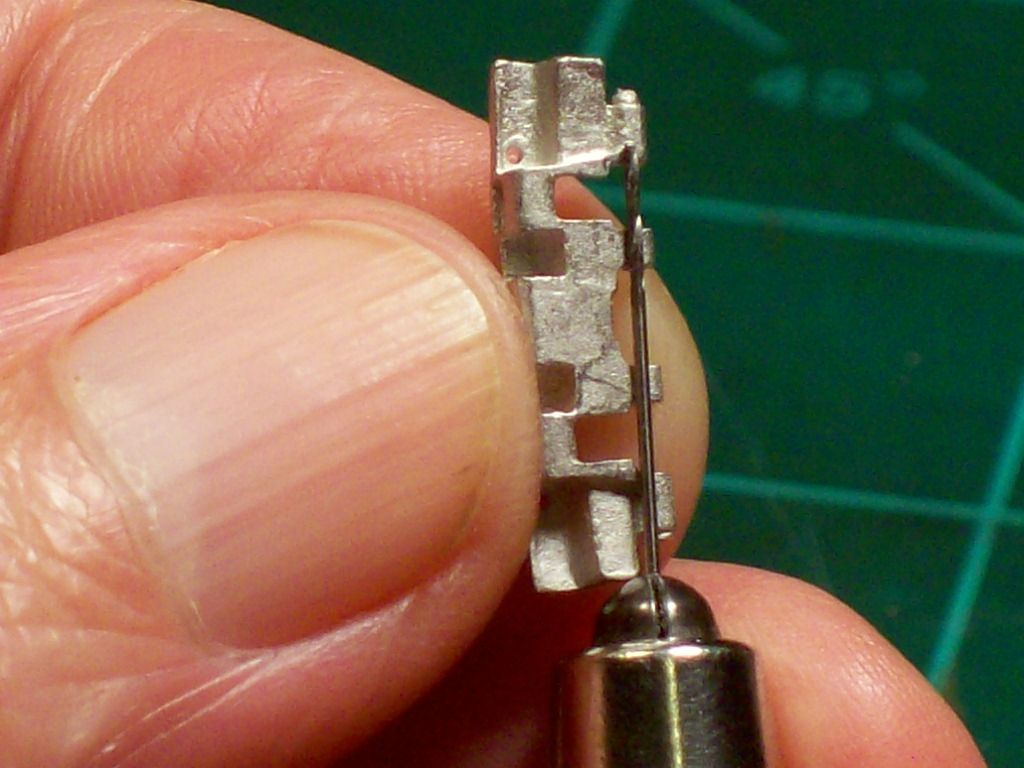

What you need to do now is set your drill bit depth so if you run across a link that the wire hole is blocked you can drill it without going all the way through destroying that cast link pin head.

You do have a pin vise???? If not get one,makes life easier.

Lets cut this off here and start a new chapter

Tony

What's in the box:

There are two packs of links because, BUT NOT ALWAYS, there are left and right sides so DON'T go and dump both bags into one big pile.

OK Here We Go:

Most everyone uses the supplied wire or brass rod to put the links together but I use dress or sequin pins on the larger tracks and the wire for the smaller tracks.

Left to right: Pz 1 and Pz 2 i'll use the wire. Pz 3&4 and larger like the Elefants shown here i'll use the pins.

I usually get a lap tray,open one of the link packs and put the links in a container. Cut the wire into manageable lengths and roll the kinks out like so with an old ignition points file.

or cut the dress pins to length. Gather the tools i'll need along with my opt-visor and then flop down in my recliner in front of the TV.

If you look at the links you'll notice one end has a hole for the wire and the other end has link pin detail cast into it. BTW that pin head detail is placed to the outside when mounting the tracks. Now you see why you need to keep the links separate and not in one pile.

What you need to do now is set your drill bit depth so if you run across a link that the wire hole is blocked you can drill it without going all the way through destroying that cast link pin head.

You do have a pin vise???? If not get one,makes life easier.

Lets cut this off here and start a new chapter

Tony