-

Modelers Alliance has updated the forum software on our website. We have migrated all post, content and user accounts but we could not migrate the passwords.

This requires that you manually reset your password.

Please click here, http://modelersalliance.org/forums/login to go to logon page and use the "Forgot your Password" option.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Airfix 1/12 Bentley blower FINISHED

- Thread starter paddy

- Start date

Are those Smiths Gauges in there?

Complex IP for for something that doesn't leave the ground.

Complex IP for for something that doesn't leave the ground.

paddy

Well-known member

As far as i can see from blowing up the pictures most of instruments are smiths Bob so maybe you have a few kicking about at workAre those Smiths Gauges in there?

Complex IP for for something that doesn't leave the ground.

Maybe some blokes back in one of the old plants in UK has some tucked away. I'm sure you know that the Smiths gauges are still being made by a small company that has no affiliation with Smiths Group but has the groups blessings.

paddy

Well-known member

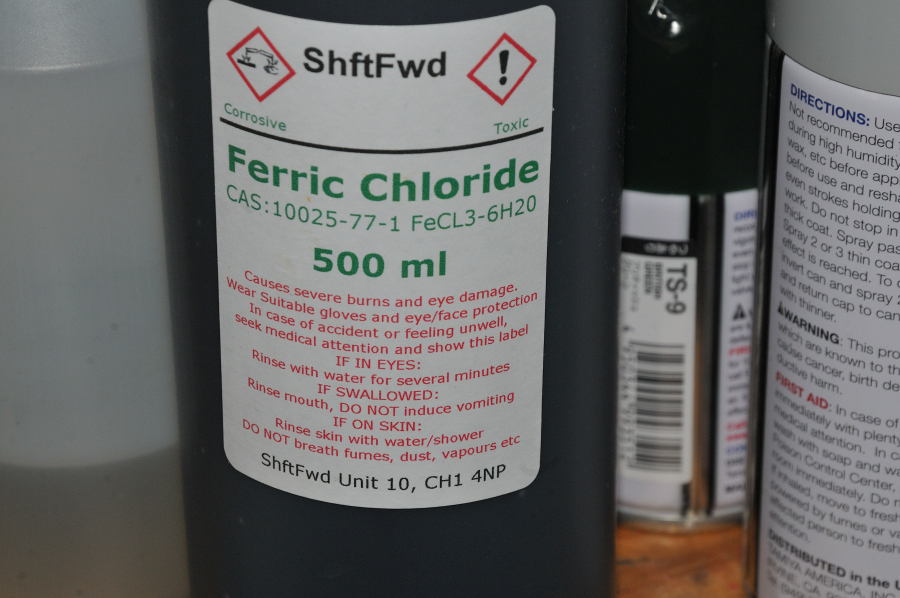

Not sure whether to put this here or in my "removing chrome " thread in the lounge.

These are some of the chrome parts. you can se large amounts of flash that was also chromed so its impossable to clean this up and keep the Airfix supplied chrome.

I have tried all the usual methods to remove the chrome from car brake fluid, bleach, oven cleaner and even caustic soda ...nothing worked and it became pretty obvious Airfix have found a way of actually chrome plating plastic (its usually a very fine Finnish alloy coating like used on car reflectors in headlamps)

eventually i stumbled across another build where the guy had used an etching fluid used on PCB's and by industry for etching Glass and steel.

Now this stuff will kill you. Just one glance at the bottle from 100yds can leave you mortally wounded.

I really dont recommend it unless you are super careful.

Parts dipped in this went back to copper in20 seconds. another sign this is real chrome.

and back to clean plastic in about 1 minute.

(forgot to take a picture ).....

Once back to plastic the parts were cleaned up and rubbed back with 4000 and then 8000 wet n dry and given an fine under coat

Next will be gloss black and alclad

the guy who's build suggested this etching fluid said it turned the plastic incredibly brittle and his online build stopped abruptly after this.

My guess is he did what most people would do and submerged the parts in this stuff and left them.. Don't do this, take them out after 1 minute and wash them with clean cold water and assess ? they may need another 15 seconds...that the sort of time scale we are talking here.

These are some of the chrome parts. you can se large amounts of flash that was also chromed so its impossable to clean this up and keep the Airfix supplied chrome.

I have tried all the usual methods to remove the chrome from car brake fluid, bleach, oven cleaner and even caustic soda ...nothing worked and it became pretty obvious Airfix have found a way of actually chrome plating plastic (its usually a very fine Finnish alloy coating like used on car reflectors in headlamps)

eventually i stumbled across another build where the guy had used an etching fluid used on PCB's and by industry for etching Glass and steel.

Now this stuff will kill you. Just one glance at the bottle from 100yds can leave you mortally wounded.

I really dont recommend it unless you are super careful.

Parts dipped in this went back to copper in20 seconds. another sign this is real chrome.

and back to clean plastic in about 1 minute.

(forgot to take a picture ).....

Once back to plastic the parts were cleaned up and rubbed back with 4000 and then 8000 wet n dry and given an fine under coat

Next will be gloss black and alclad

the guy who's build suggested this etching fluid said it turned the plastic incredibly brittle and his online build stopped abruptly after this.

My guess is he did what most people would do and submerged the parts in this stuff and left them.. Don't do this, take them out after 1 minute and wash them with clean cold water and assess ? they may need another 15 seconds...that the sort of time scale we are talking here.

Nice job, be careful with that stuff!

Heavens Eagle

Well-known member

I used that stuff for years to etch prototype circuit boards. It does have a smell, but the odor isn't the problem. If you take precautions in handling it you should have no problems at all.

In fact it seems I suggested this stuff in your chrome removal thread. Rubber gloves, glass or plastic containers to soak the parts, and LOTS of water to rinse things off.

Congrats on finally getting the shiny off!

In fact it seems I suggested this stuff in your chrome removal thread. Rubber gloves, glass or plastic containers to soak the parts, and LOTS of water to rinse things off.

Congrats on finally getting the shiny off!

paddy

Well-known member

Here we see the Queen demonstrating the glasses for the instrument panel

but shift the light and you get this

Has anyone ever tried to flatten and polish these types of glasses ? I was wondering about a flat plate and some really fine sanding sheets, i have some 8000 grit ?

I'm sure you know progressive sanding to polishing. I've never tried to do what you're looking at doing so not much help. I do wonder if clear resin replacement would be better?

Iron Mike

Master At Arms And Resident Curmudgeon

Your idea about flattening the bezels is what I would do, polishing progressively with finer grits and finishing with Flitz or Simichrome polish.

Novus plastic polish works pretty well, but not as well as Flitz.

Flitz!

Recently, Chris and I were discussing Opti-Visors and he told me that he uses Flitz polish on his lens. I have used other metal and plastic polishes, but had not tried Flitz. Our local hardware store had a tube in stock, so I brought it home and used a small dab on my old Opti-Visor's lens...

modelersalliance.org

Impisi

Well-known member

Well I've not done it with those kind of glasses but with the canopy on my B-2 build. I had only some nail polish sticks numbered 1,2, 3 - so I don't know the grid of those, after that some tooth paste polish and some car polish without wax and in the end an dip in future - it worked quite well

paddy

Well-known member

Today i had my first real attempt with Aclad dont think i have ever needed to spray chrome on tanks or Aircraft

Very pleased with the results, As you might expect its 99% preparation, The better your plastic prep ie: ultra smooth, your black base coat, the better the chrome finish

i used Tamiya fine primer then Tamiya gloss black then alclad chrome

Its hard to take good pictures of chrome but these parts are better than they look and more importantly they are cleaned up with out attachment points and flash

I have stood a bottle next to the radiator so you can see the reflection. Very pleased

Very pleased with the results, As you might expect its 99% preparation, The better your plastic prep ie: ultra smooth, your black base coat, the better the chrome finish

i used Tamiya fine primer then Tamiya gloss black then alclad chrome

Its hard to take good pictures of chrome but these parts are better than they look and more importantly they are cleaned up with out attachment points and flash

I have stood a bottle next to the radiator so you can see the reflection. Very pleased

Nice job!