Hawkwrench

Active member

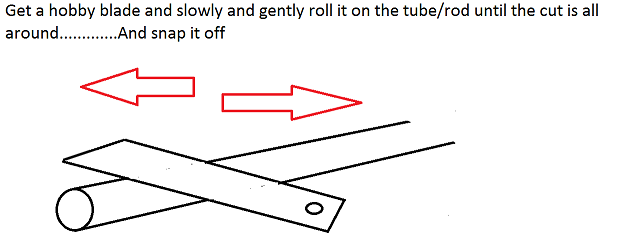

I've got a question about sanding edges of tubing or rod. To get a flat squared edge, obviously the right way is to put it on your miter box and cut it, but how do you get that same flat squared edge when you can't use the miter box?

Tim

Tim